| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

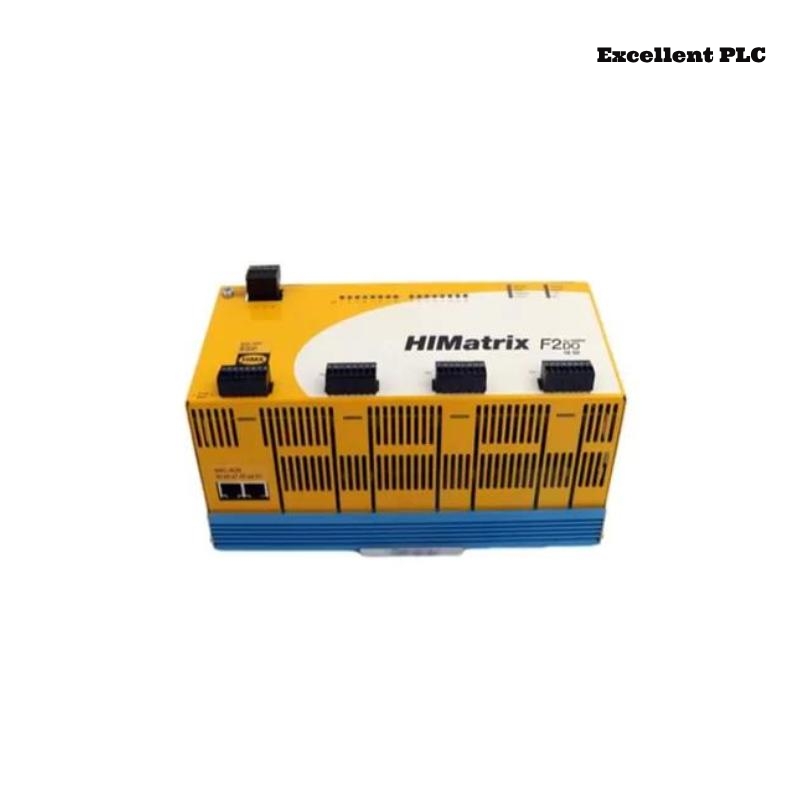

Product Overview

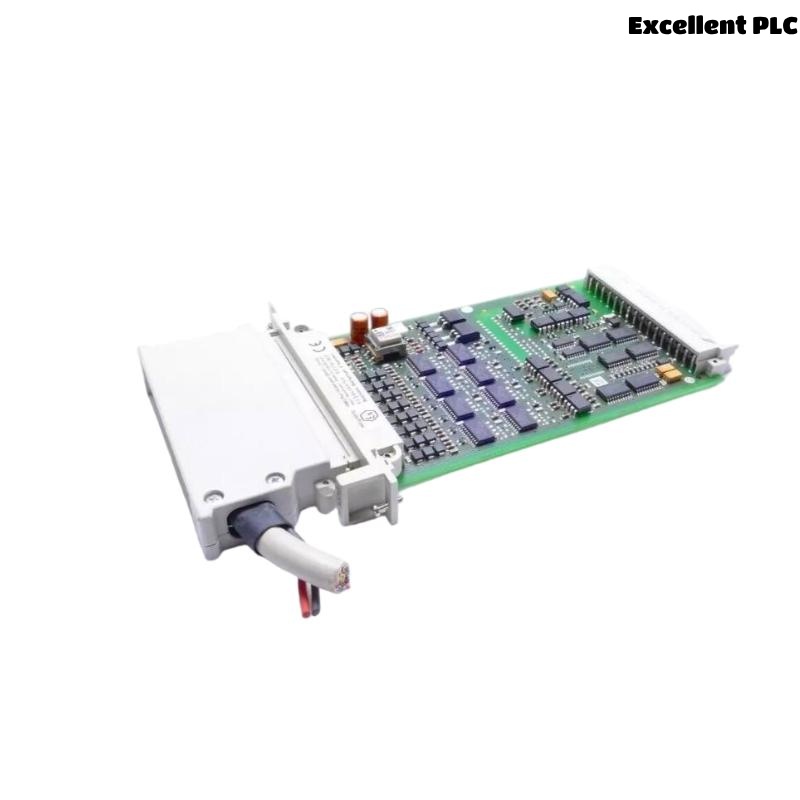

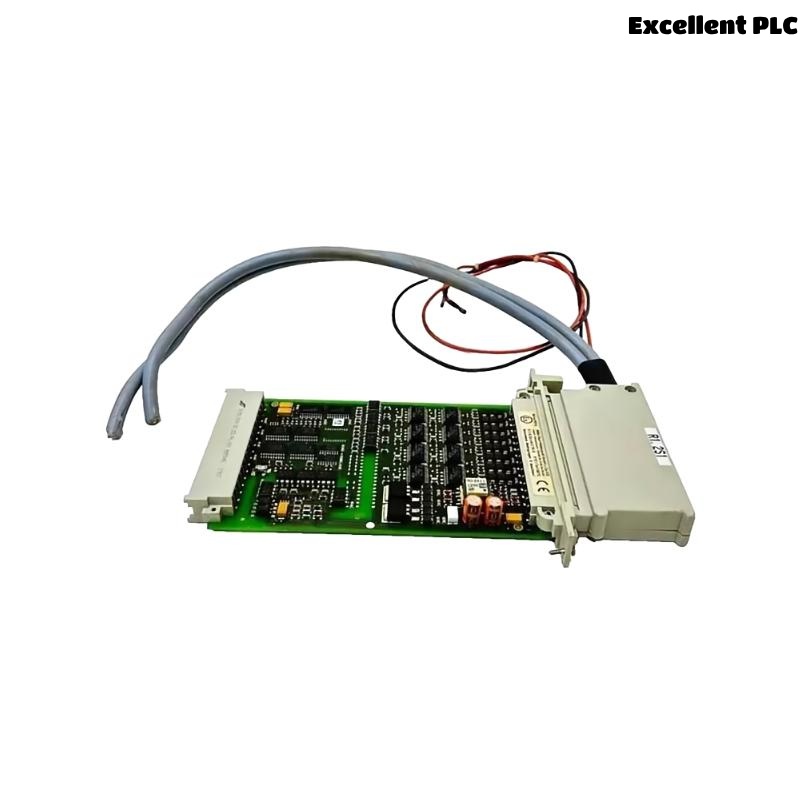

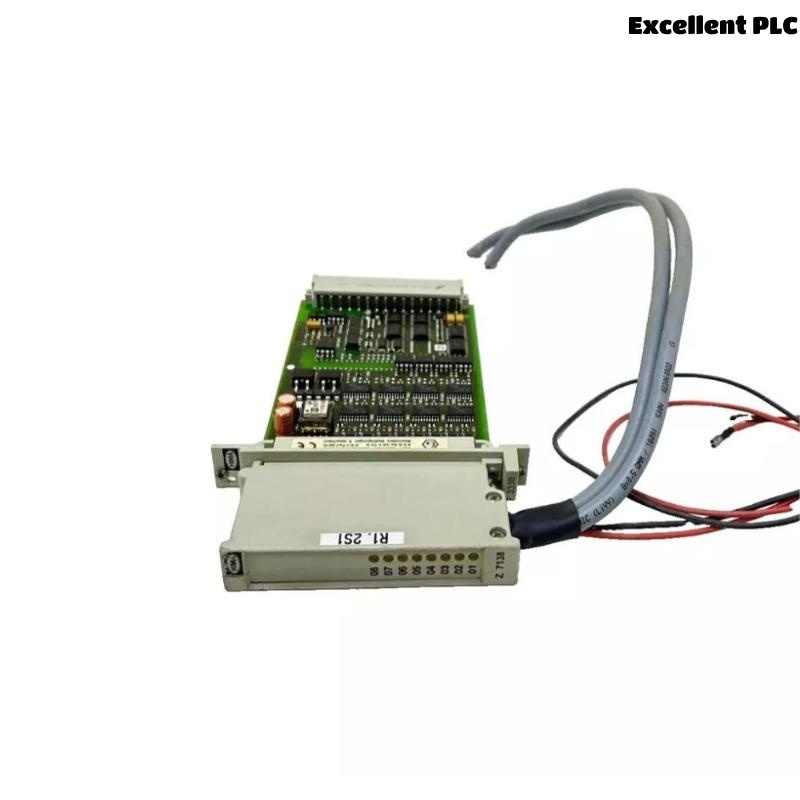

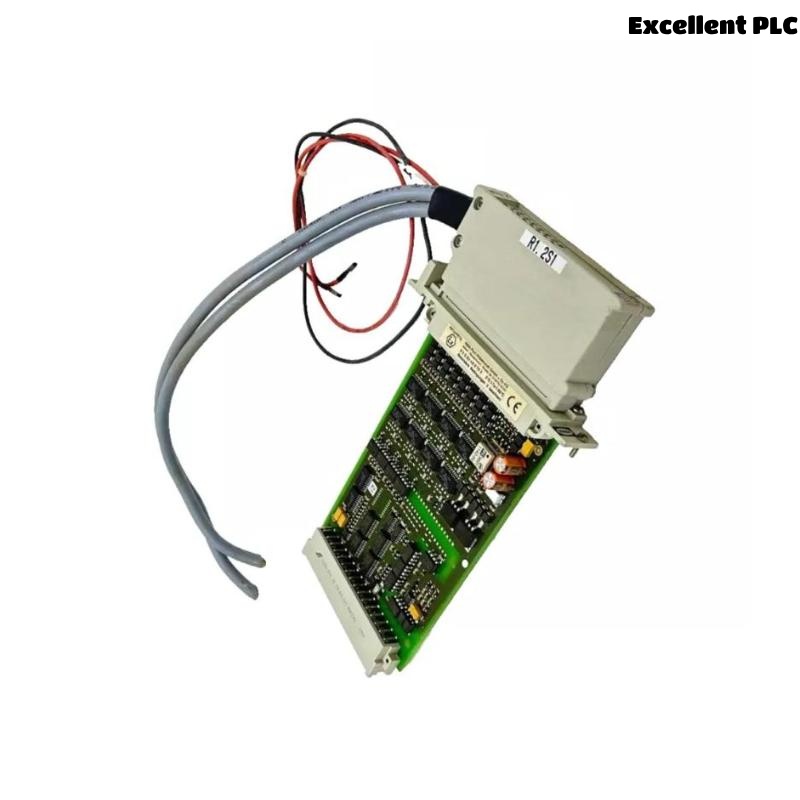

The HIMA F2 DO 16 02 is a highly reliable Remote I/O Module designed for use in safety-critical systems, particularly in Safety Instrumented Systems (SIS). As part of the HIMA F2 series, the F2 DO 16 02 module provides 16 digital outputs for controlling safety functions in environments where system integrity is crucial. It is used extensively in industries like oil and gas, chemical processing, and power generation, where safety is paramount, and any failure could lead to serious consequences.

This module integrates seamlessly into HIMA’s SIL-rated systems, offering high fault tolerance and redundant architecture to ensure that safety functions remain operational even in the event of component failures. The F2 DO 16 02 can control and monitor multiple devices simultaneously, and with its ability to interface with a variety of input and output devices, it provides flexibility for a wide range of industrial applications.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | F2 DO 16 02 |

| Type | Remote I/O Module |

| Input/Output | 16 Digital Outputs (Relay-Based) |

| Power Supply | 24V DC (nominal) |

| Nominal Voltage | 24V DC |

| Dimensions (HxWxD) | 255 x 114 x 113 mm |

| Weight | 2 kg |

| Operating Temperature | -40°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Power Consumption | 7W |

| Communication Protocol | Profibus, Modbus, HART, Ethernet |

| Safety Integrity Level (SIL) | SIL 3 |

| Mounting Type | DIN Rail Mounting |

| Enclosure Type | IP20 |

| Certifications | CE, UL, ATEX, IECEx, SIL 3 |

Applications

The HIMA F2 DO 16 02 module is designed for use in safety-critical applications where reliability and fault tolerance are key. Some key applications include:

-

Safety Instrumented Systems (SIS)

The F2 DO 16 02 module is commonly used in Safety Instrumented Systems for monitoring and controlling critical safety functions. -

Emergency Shutdown Systems (ESD)

It is essential for triggering emergency shutdown processes in hazardous environments, ensuring the safety of personnel and assets. -

Process Automation in Oil & Gas

The F2 DO 16 02 controls safety-related equipment, such as valves and pumps, in the oil and gas sector. -

Chemical and Petrochemical Plants

Used in chemical plants to control digital outputs that interact with safety devices like pressure relief valves and gas detectors. -

Power Generation

In power plants, the module ensures that emergency shutdowns and other safety functions are performed reliably and efficiently.

Advantages

-

High Safety Integrity (SIL 3 Certified)

The F2 DO 16 02 module is certified to SIL 3, ensuring it meets the highest safety standards for critical systems, reducing the risk of failure in hazardous environments. -

Compact and Robust Design

Designed for both space-constrained and harsh industrial environments, the F2 DO 16 02 is compact yet robust, able to withstand challenging operational conditions. -

Flexibility and Scalability

The module supports Profibus, Modbus, HART, and Ethernet communication protocols, ensuring easy integration into existing control systems while providing flexibility for future upgrades. -

Fast and Reliable Operation

With 16 digital relay outputs, the module offers high-speed, reliable switching, essential for safety-related functions in industrial environments. -

Seamless Integration

The module easily integrates with other HIMA products, such as F2 CPUs and F2 I/O Modules, creating a unified, highly reliable safety system that can be easily scaled and expanded. -

High Fault Tolerance

Featuring redundant design and self-diagnosing capabilities, the module offers high fault tolerance, ensuring that system failure does not compromise safety functions.

Latest News

-

“HIMA F2 DO 16 02 Achieves SIL 3 Certification”

HIMA recently announced that the F2 DO 16 02 module has received SIL 3 certification, meeting the highest safety standards for industrial applications. -

“New Features Enhance the HIMA F2 DO 16 02 for Remote Monitoring”

A new firmware update for the F2 DO 16 02 adds enhanced remote monitoring capabilities, improving overall system diagnostics and reducing maintenance costs. -

“F2 DO 16 02 Improves Process Safety in the Chemical Industry”

The module has been successfully integrated into several chemical plants, where it is being used to monitor and control critical safety systems, improving uptime and safety. -

“HIMA F2 Series Now Compatible with New Safety Networks”

The F2 DO 16 02 now supports newer safety network protocols, offering increased interoperability with modern control systems in various industries.

Frequently Asked Questions (FAQ)

-

What is the primary function of the HIMA F2 DO 16 02 module?

The HIMA F2 DO 16 02 is a Remote I/O Module designed for safety applications, providing 16 relay-based digital outputs for controlling safety-critical systems. -

What safety certifications does the F2 DO 16 02 have?

The module is SIL 3 certified, ensuring it meets the highest safety standards for use in critical industrial applications. -

What communication protocols does the F2 DO 16 02 support?

It supports Profibus, Modbus, HART, and Ethernet, making it compatible with a wide range of industrial control systems. -

How many outputs does the F2 DO 16 02 provide?

The F2 DO 16 02 provides 16 digital relay outputs, which can control various safety devices. -

What is the operating temperature range of the F2 DO 16 02?

The module operates in temperatures from -40°C to 70°C, suitable for use in both indoor and outdoor environments. -

What is the power consumption of the F2 DO 16 02?

The module consumes approximately 7W of power. -

Is the F2 DO 16 02 suitable for hazardous areas?

Yes, it is certified for use in hazardous areas, with ATEX and IECEx certifications ensuring it meets the standards for explosive atmospheres. -

How does the F2 DO 16 02 ensure fault tolerance?

It features redundant design and self-diagnostics that ensure the module remains operational even in the event of a fault. -

Can the F2 DO 16 02 be used in a distributed control system?

Yes, the module is ideal for use in distributed control systems (DCS), thanks to its robust communication protocols and high reliability. -

What is the typical weight and size of the F2 DO 16 02 module?

The module has dimensions of 255 x 114 x 113 mm and weighs 2 kg.

Related Models

Here are 10 related models from the HIMA F2 series:

| Model | Description | Key Features |

|---|---|---|

| F2 DO 16 01 | Digital Output Module with 16 channels | SIL 3, Profibus, Modbus |

| F2 AI 8 02 | Analog Input Module with 8 channels | SIL 3, High-Precision Inputs |

| F2 DI 8 02 | Digital Input Module with 8 channels | SIL 3, Fast Response Times |

| F2 DO 8 01 | Digital Output Module with 8 channels | SIL 3, Flexible Output Configuration |

| F2 DIO 16 02 | Digital Input/Output Module with 16 channels | SIL 3, Profibus |

| F2 RTD 4 02 | RTD Input Module for Temperature Measurement | SIL 3, High Accuracy |

| F2 AI 4 02 | Analog Input Module with 4 channels | SIL 3, Wide Input Range |

| F2 DO 32 01 | High-density Digital Output Module with 32 channels | SIL 3, Profibus |

| F2 CI 16 02 | Communication Interface Module | Ethernet, SIL 3 |

| F2 IO 8 01 | Compact I/O Module with 8 channels | SIL 3, High Reliability |

Popular Models from HIMA

Here are 10 popular models from HIMA that you may find useful:

| Model | Description | Key Features |

|---|---|---|

| F3-20 | Process Control System | Modular, SIL 3 |

| F3-40 | Safety Control System | SIL 3, Flexible I/O |

| F3-60 | Advanced Safety System | High-Performance CPU, SIL 3 |

| F3-70 | High Availability System | Redundant Architecture, SIL 3 |

| F3-100 | Fully Redundant System | Ethernet, SIL 3 |

| F4-20 | Digital I/O System | SIL 3, Modbus, Profibus |

| F4-40 | Analog I/O System | SIL 3, Accurate Analog Inputs |

| F5-50 | Fieldbus I/O System | HART, SIL 3 |

| F6-60 | Wireless I/O System | High Scalability, SIL 3 |

| F7-70 | Safety I/O System | Compact Design, SIL 3 |

Excellent PLC

Excellent PLC