| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

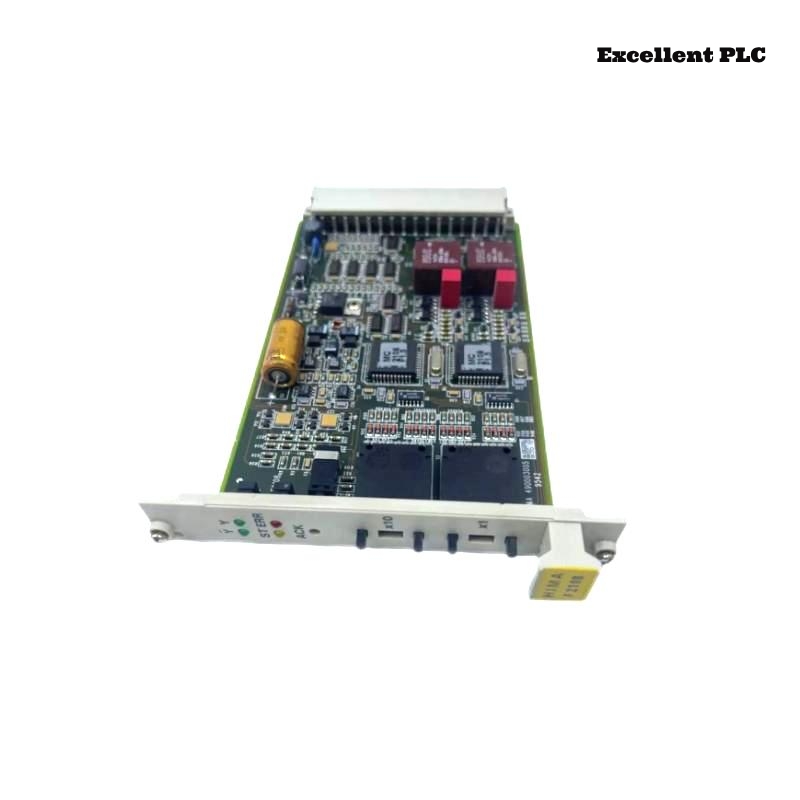

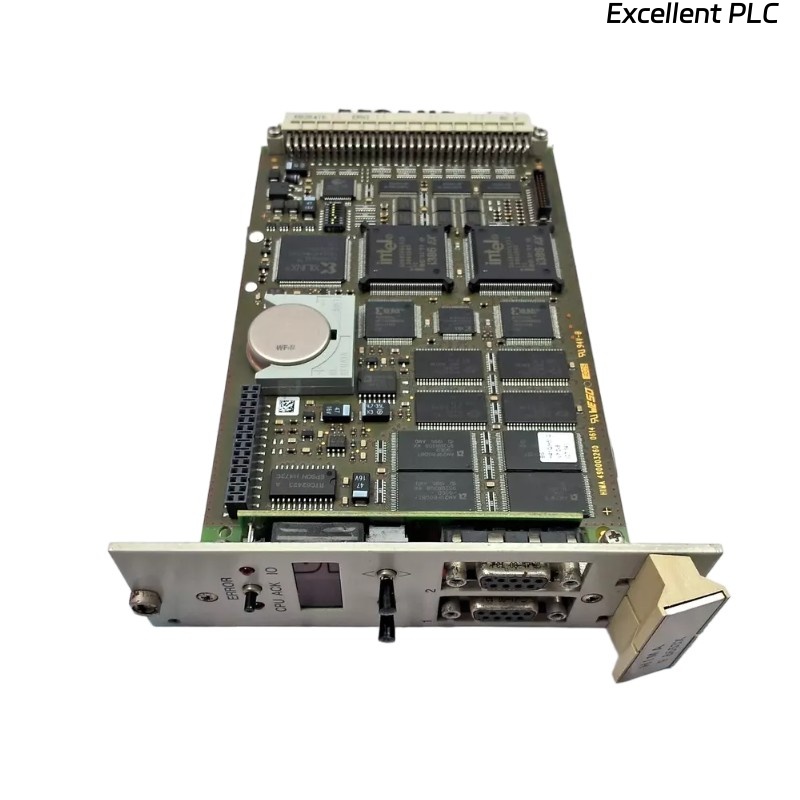

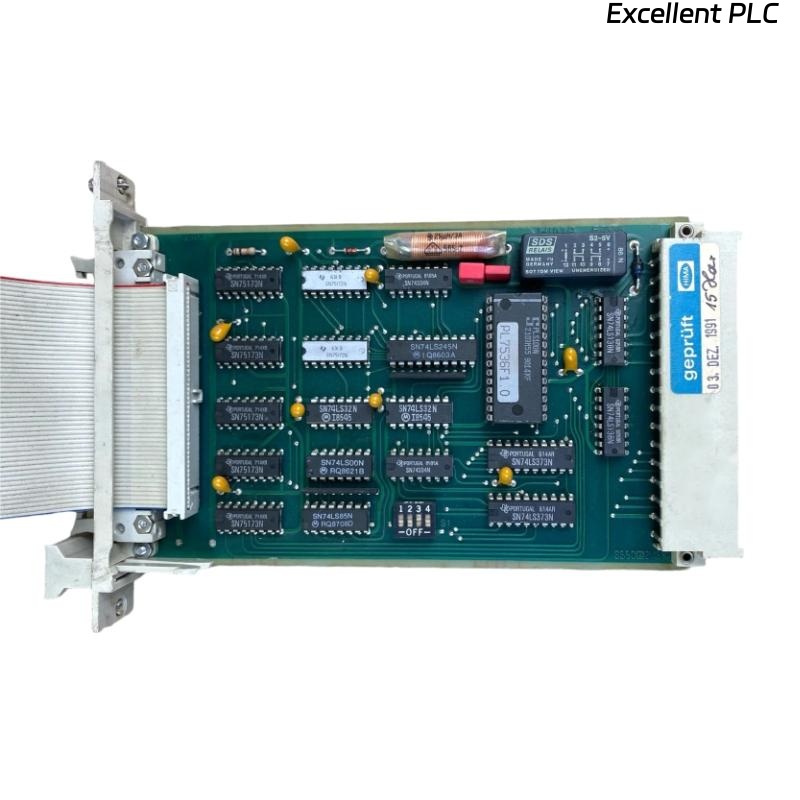

Product Introduction

The HIMA F2108 Safety-Related Multifunctional Delay Module is a high-precision, safety-certified timing module designed for critical industrial applications. It provides reliable time-delay functions for safety-related processes, ensuring that systems respond correctly within pre-defined timeframes. This module is an integral part of HIMA’s safety automation systems, which are widely used in industries such as oil & gas, chemical processing, power generation, and manufacturing.

With its SIL3 certification, the F2108 guarantees high reliability and fault tolerance, making it an ideal choice for applications that require precise control over delayed activation and deactivation of safety functions. Its flexible configuration allows it to be adapted to various safety automation tasks, including emergency shutdowns (ESD), alarm sequencing, and controlled process timing.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | HIMA F2108 Safety-Related Multifunctional Delay Module |

| Function | Safety-related time delay control module |

| Input Voltage | 24V DC (nominal) |

| Power Consumption | Approx. 3.5W |

| Timer Functions | Delay-on, delay-off, pulse generation, interval timing |

| Response Time | < 5 ms |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN rail mounting |

| Safety Certification | SIL3 (IEC 61508) |

| Communication Interface | Compatible with HIMA safety systems |

| Dimensions | 160 x 120 mm |

| Weight | 0.8 kg |

| Compliance | IEC 61508, EN 50156-1, ATEX certified |

Applications

The HIMA F2108 is widely used in industrial and safety-critical applications requiring precise timing control. Key application areas include:

1. Emergency Shutdown (ESD) Systems

- Ensures a controlled delay before activating an emergency shutdown sequence to prevent unnecessary system trips.

2. Process Safety in Chemical and Petrochemical Industries

- Used to manage time-based safety interlocks, ensuring critical reactions occur in a controlled sequence.

3. Power Plant Automation

- Provides precise delay timing in turbine control systems, preventing premature shutdowns or system faults.

4. Oil & Gas Industry

- Used in offshore and onshore facilities for pipeline safety and flare system control.

5. Alarm & Notification Sequencing

- Implements controlled delays for alarm activations to avoid unnecessary disturbances and false alarms.

6. Industrial Automation & Manufacturing

- Controls the timed operation of safety devices such as emergency stops, protective barriers, and machine interlocks.

Advantages of HIMA F2108

- High Safety Certification (SIL3) – Ensures reliability in mission-critical safety applications.

- Multifunctional Timer Capabilities – Supports multiple timing functions such as delay-on, delay-off, pulse timing, and interval timing.

- Fast Response Time (<5ms) – Ensures accurate and quick reaction in emergency and automation processes.

- Wide Operating Temperature Range (-25°C to +70°C) – Suitable for harsh industrial environments.

- Energy Efficient (3.5W Power Consumption) – Reduces overall energy costs and system heat generation.

- Compact DIN Rail Mounting – Space-saving design for easy integration into control panels.

- Compatible with HIMA Safety Systems – Seamless integration with other HIMA automation and safety modules.

- Fault-Tolerant Design – Minimizes risks of failure in safety applications, ensuring continuous operation.

- Easy Configuration & Maintenance – Configurable via HIMA’s proprietary software tools, allowing for quick setup.

- Certified for Hazardous Environments – Complies with IEC 61508 and ATEX standards for use in explosive atmospheres.

Latest News Titles

- March 2025: HIMA F2108 successfully deployed in large-scale refinery safety systems.

- February 2025: HIMA introduces firmware update for F2108 to enhance timer flexibility.

- December 2024: F2108 module passes rigorous testing in extreme temperature conditions.

- October 2024: HIMA expands product portfolio with advanced multifunctional safety timers.

- July 2024: Global demand increases for HIMA F2108 in offshore oil & gas applications.

Frequently Asked Questions (FAQs)

1. What is the primary function of the HIMA F2108 module?

The F2108 is a safety-related multifunctional delay module used for time-controlled safety applications.

2. What industries commonly use the F2108?

Industries such as oil & gas, power generation, chemical processing, and manufacturing rely on the F2108 for precise safety timing.

3. What certifications does the F2108 have?

It is SIL3-certified and complies with IEC 61508, EN 50156-1, and ATEX for hazardous environments.

4. Can I configure different delay times with the F2108?

Yes, the module supports configurable delay-on, delay-off, and pulse timing through HIMA’s software tools.

5. What is the response time of the module?

The F2108 has a response time of less than 5ms, ensuring high-speed safety reactions.

6. How is the module mounted?

It features DIN rail mounting, allowing for easy installation in industrial control panels.

7. What is the operating temperature range?

The module operates between -25°C and +70°C, making it suitable for extreme environments.

8. How much power does the F2108 consume?

It has a low power consumption of approximately 3.5W, making it energy efficient.

9. Is the F2108 compatible with older HIMA systems?

Yes, it integrates seamlessly with HIMA’s existing safety automation platforms.

10. Can the F2108 be used in hazardous environments?

Yes, it meets ATEX and IEC 61508 standards, making it suitable for explosion-prone locations.

Related Models (Same Series or Similar Functionality)

| Model Number | Description |

|---|---|

| F2103a | Safety Timer Module with multi-function delay options |

| F2104a | Extended Delay Timer with advanced safety features |

| F2201a | Digital Input Module with time-based control functions |

| F2501a | High-speed Timer and Process Control Module |

| F2301a | Safety Relay Module with time delay integration |

| F2203a | Pulse Input Module for advanced timer applications |

| F2303a | Digital Output Module with programmable delay functions |

| F2502a | Enhanced Multifunction Timer with dual-channel operation |

| F2402a | Power Supply Module for HIMA safety systems |

| F3201a | Signal Processing Module with integrated timing functions |

Popular HIMA Models

| Model Number | Description |

|---|---|

| F3101a | High-performance Safety Communication Module |

| F2001a | Modular Safety Controller for automation systems |

| F3300a | Digital Output Module with fail-safe redundancy |

| F3401a | Universal Safety I/O Module for flexible applications |

| F3102a | Field Interface Module with integrated diagnostics |

| F3500a | High-capacity Output Module for industrial controls |

| F2400a | Advanced Safety Relay Output Module |

| F2200a | Digital Input Module for time-sensitive applications |

| F3200a | Digital Signal Processor for automation control |

| F3105a | Remote Safety Monitoring Module |

Excellent PLC

Excellent PLC