| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

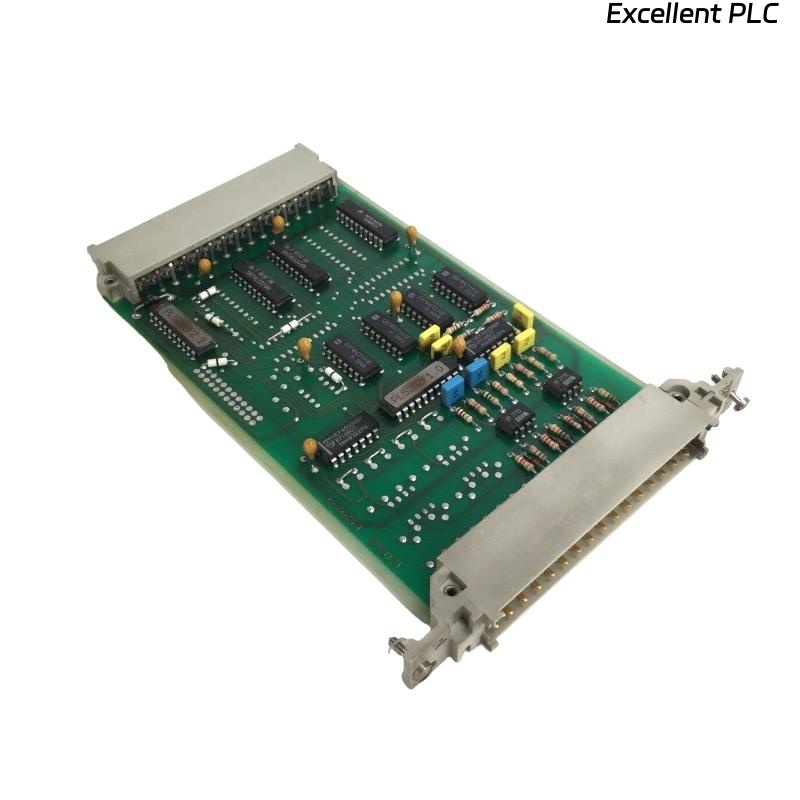

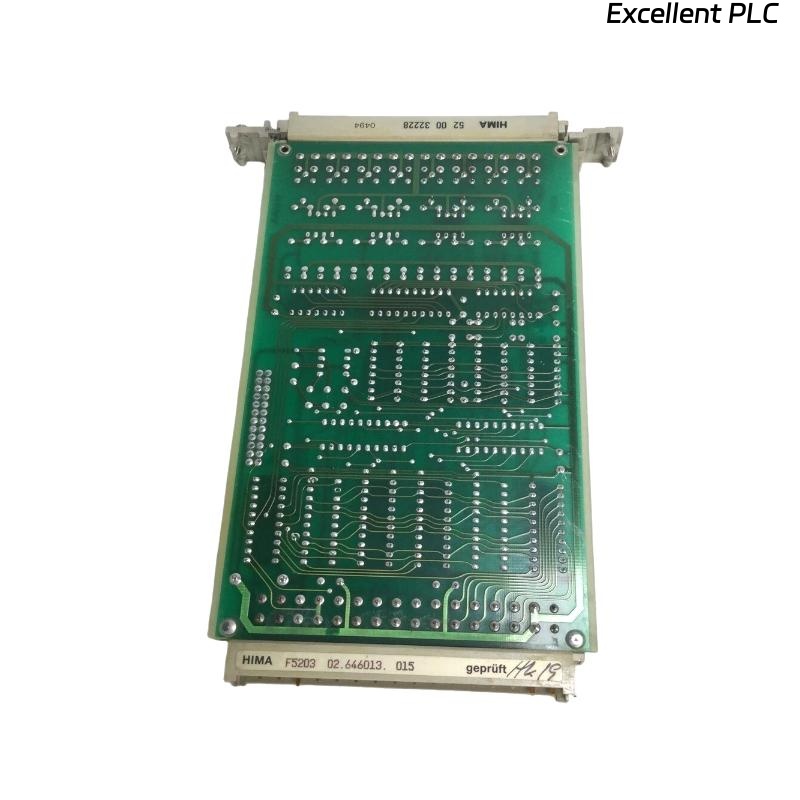

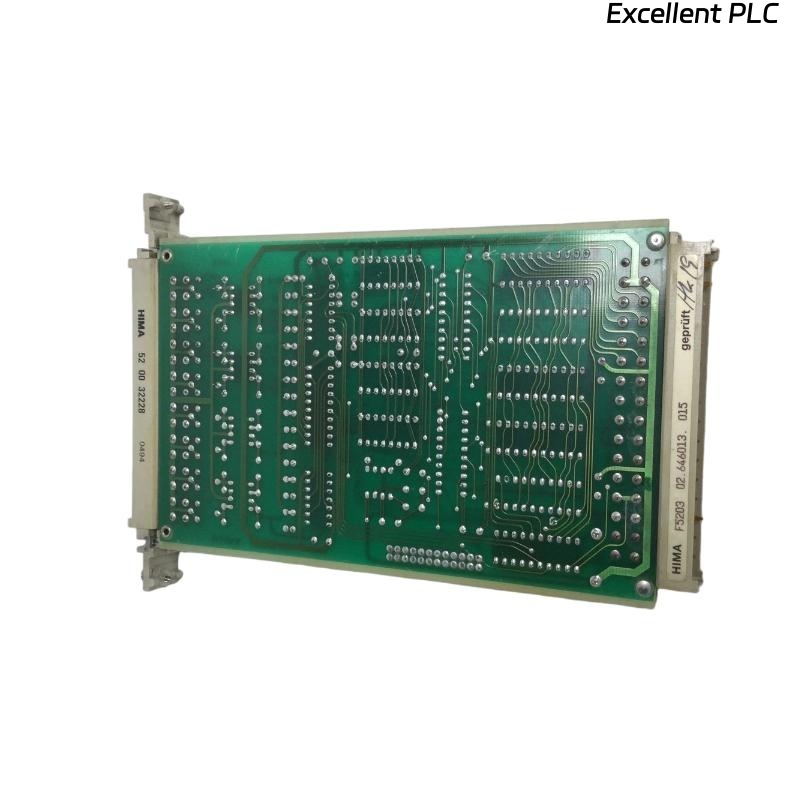

Product Introduction

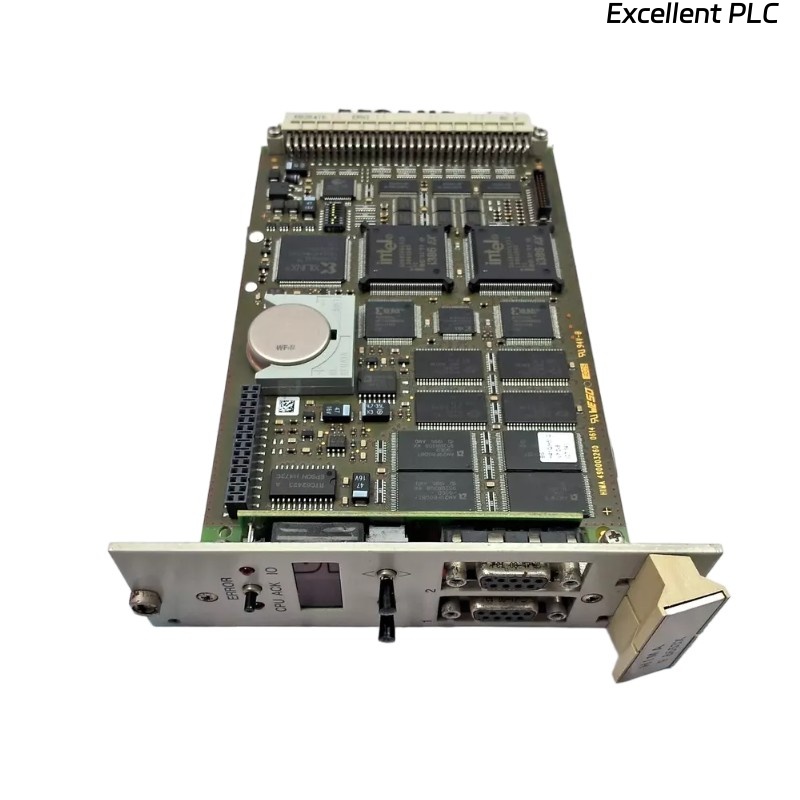

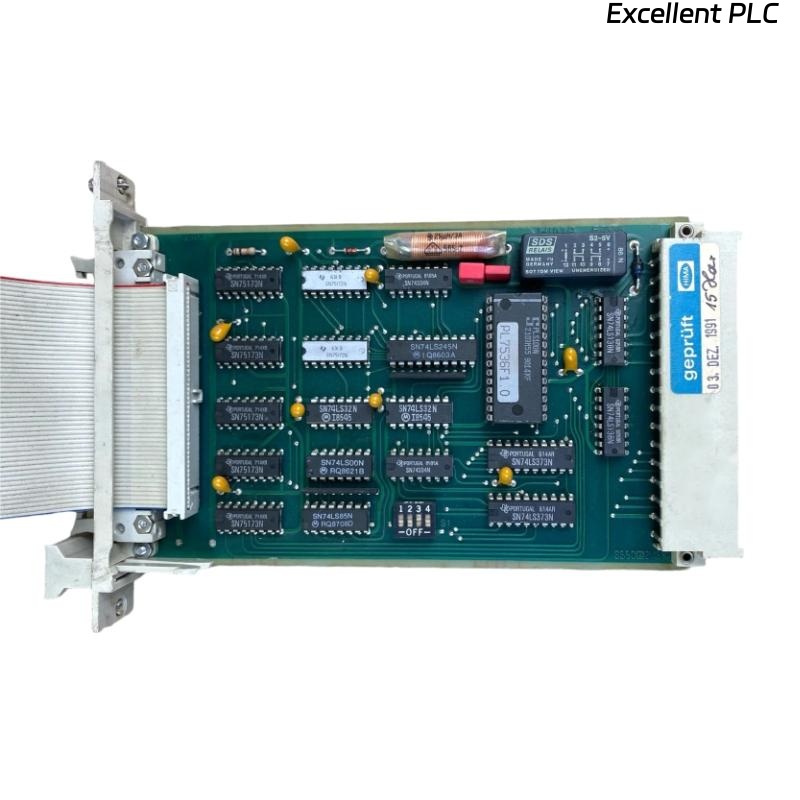

The HIMA F5203 Control Panel is a robust and high-performance module designed to operate within HIMA’s safety and automation platform. It is specifically engineered to provide reliable control, monitoring, and safety functions in critical process applications. With a strong emphasis on system integrity and fault tolerance, the F5203 integrates seamlessly with other HIMA modules to create a scalable and flexible automation solution.

The unit supports advanced I/O processing, diagnostic capabilities, and redundancy concepts, making it well-suited for industries that demand the highest levels of safety, such as oil and gas, petrochemical, power generation, and industrial manufacturing.

Product Parameters

| Parameter | Description |

|---|---|

| Product Model | HIMA F5203 Control Panel |

| Function | Control and safety panel for HIMA automation systems |

| Input Channels | Up to 32 configurable inputs (digital/analog depending on system setup) |

| Output Channels | Up to 32 configurable outputs (digital/relay/analog supported) |

| Communication Interfaces | Redundant bus communication, Modbus, Profibus, Ethernet |

| Power Supply | 24 VDC (typical) |

| Operating Temperature | -20°C to +70°C |

| Cooling Method | Natural convection or rack-mounted forced air |

| Diagnostic Features | Built-in self-test, error logging, channel fault detection |

| Redundancy Support | Yes, supports hot-standby redundancy and failover |

| Mounting Type | 19-inch rack mounting |

| Dimensions (H × W × D) | 200 × 100 × 30 mm |

| Weight | 0.2 kg |

Product Applications

The HIMA F5203 Control Panel is widely applied in industries where process safety and precise control are mandatory. Typical application areas include:

-

Oil & Gas: Monitoring drilling operations, pipeline safety systems, and wellhead control.

-

Petrochemical Plants: Ensuring safe shutdown procedures, flare management, and reactor safety.

-

Power Generation: Turbine control, emergency shutdown, and auxiliary systems monitoring.

-

Transportation: Safety management systems for railways and industrial transport equipment.

-

Manufacturing: Process automation, machine safety, and production line fault handling.

-

Energy Distribution: Monitoring and control of substations, renewable energy plants, and critical infrastructure.

Product Advantages

-

High Reliability: Engineered for continuous operation in demanding environments with minimal downtime.

-

Advanced Safety Features: Integrated diagnostic tools and redundancy concepts ensure safe operations.

-

Flexibility: Configurable inputs and outputs for a wide range of control scenarios.

-

Scalability: Works seamlessly with other HIMA modules to expand system capacity.

-

Redundancy Support: Hot-swappable and redundant architecture to maximize uptime.

-

Compliance: Designed to meet international safety standards such as IEC 61508 (SIL-rated systems).

-

Ease of Integration: Compatible with multiple industrial communication protocols for seamless connectivity.

FAQ

-

What type of inputs and outputs does the F5203 support?

The module supports both digital and analog signals, configurable based on process requirements. -

Does the F5203 support redundant operation?

Yes, it supports hot-standby redundancy, ensuring uninterrupted operation in case of module failure. -

How does the module perform diagnostics?

It has built-in self-test routines, continuous error monitoring, and channel-specific fault detection. -

Which communication protocols are supported?

The module supports Modbus, Profibus, and Ethernet, along with HIMA’s proprietary safety communication bus. -

Can the module be hot-swapped during operation?

Yes, the F5203 can be replaced without shutting down the entire system, minimizing downtime. -

What is the maximum number of I/O points that can be connected?

The module supports up to 64 combined I/O points depending on configuration. -

Is the F5203 compatible with legacy HIMA systems?

Yes, it is backward compatible with selected older HIMA rack systems, ensuring upgrade flexibility. -

How does the F5203 handle fault isolation?

Faulty channels are isolated automatically, preventing system-wide disruptions. -

Does the control panel support safety-certified applications?

Yes, it is suitable for SIL-rated safety applications under IEC 61508 standards. -

What are the cooling requirements for the module?

It relies on natural convection under normal conditions but can also be installed with forced rack ventilation for higher-density systems.

Recommended Related Models (Same Series or Similar)

| Model | Description |

|---|---|

| HIMA F5221 | Digital Input Module |

| HIMA F5222 | Digital Output Module |

| HIMA F3236 | Analog Input Module |

| HIMA F8627X | Communication Interface Module |

| HIMA F3330 | Analog Output Module |

| HIMA F6705 | Power Supply Module |

Recommended Popular Models (Same Brand – HIMA)

| Model | Description |

|---|---|

| HIMA F7133 | Digital Output Module with diagnostics |

| HIMA F4204 | Analog Input Module for process signals |

| HIMA K9203B | Rack Cooling Fan Unit |

| HIMA F3109 | High-density Analog Input Module |

| HIMA F8627X | Advanced Communication Gateway |

| HIMA F3331 | Analog Output Module with redundancy |

Excellent PLC

Excellent PLC