| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

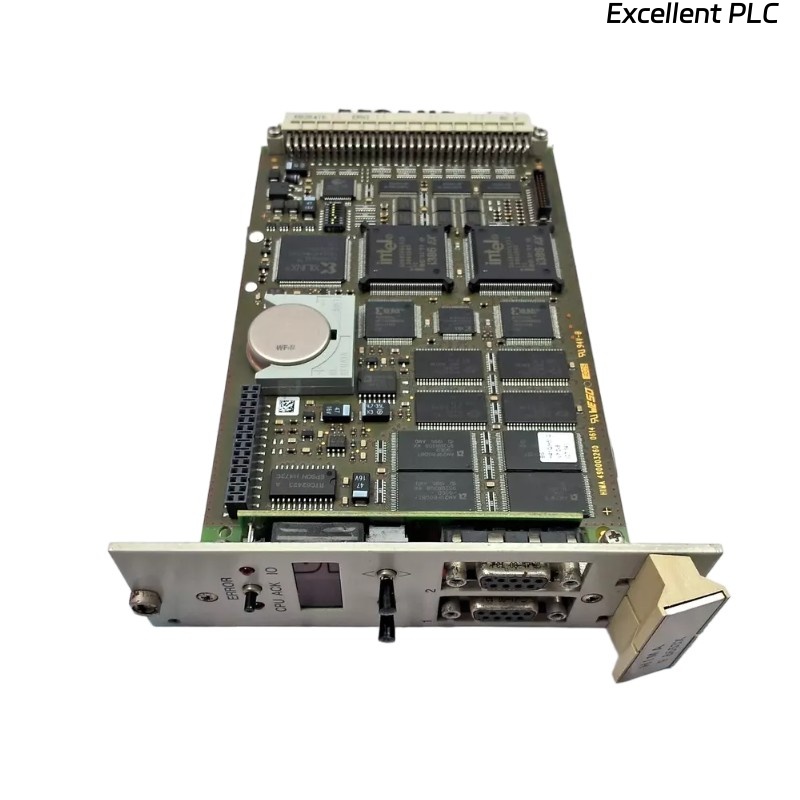

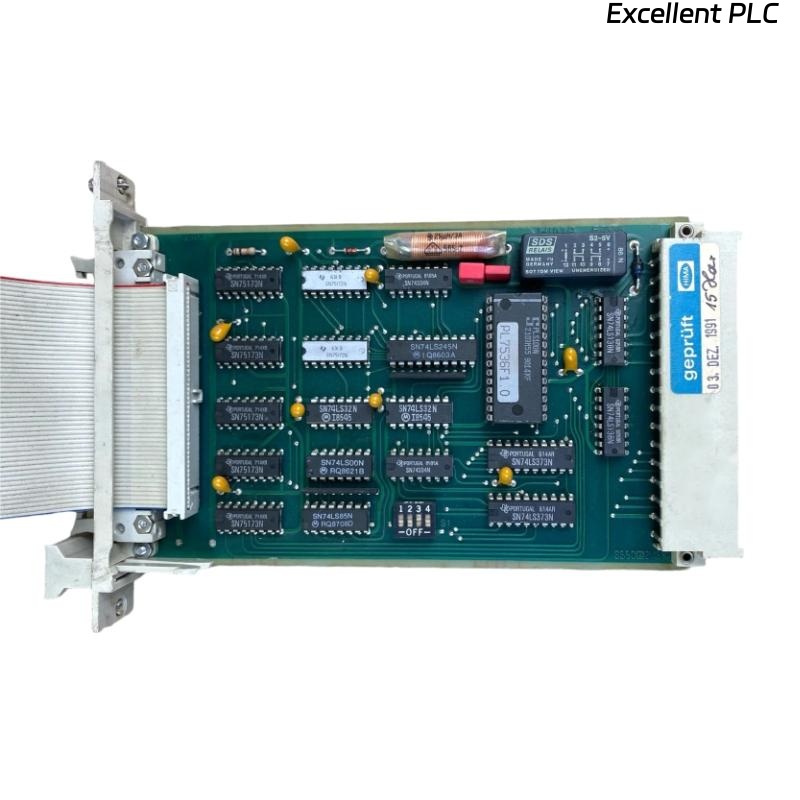

Product Introduction

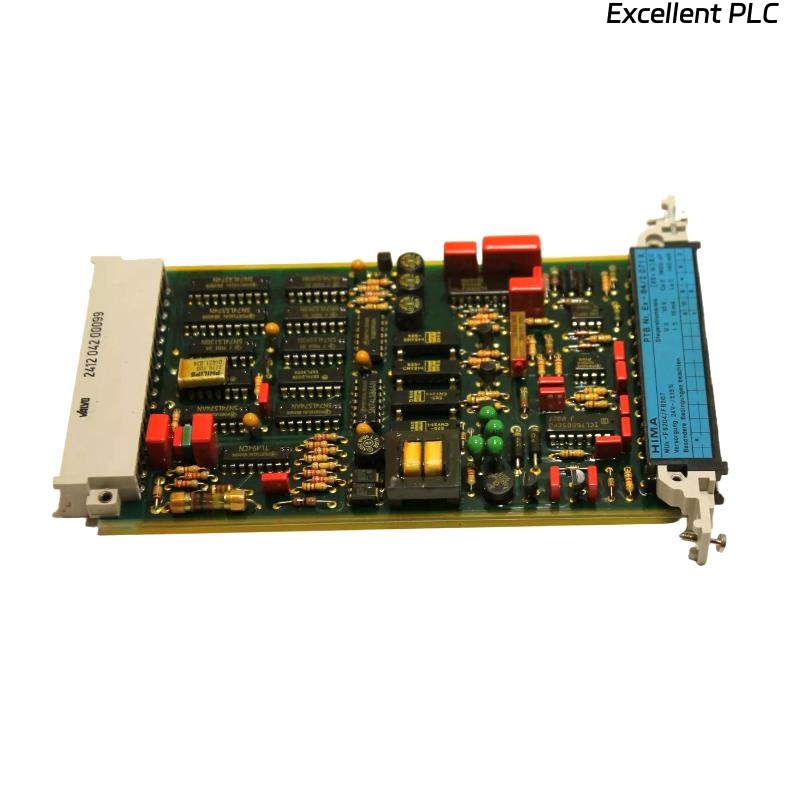

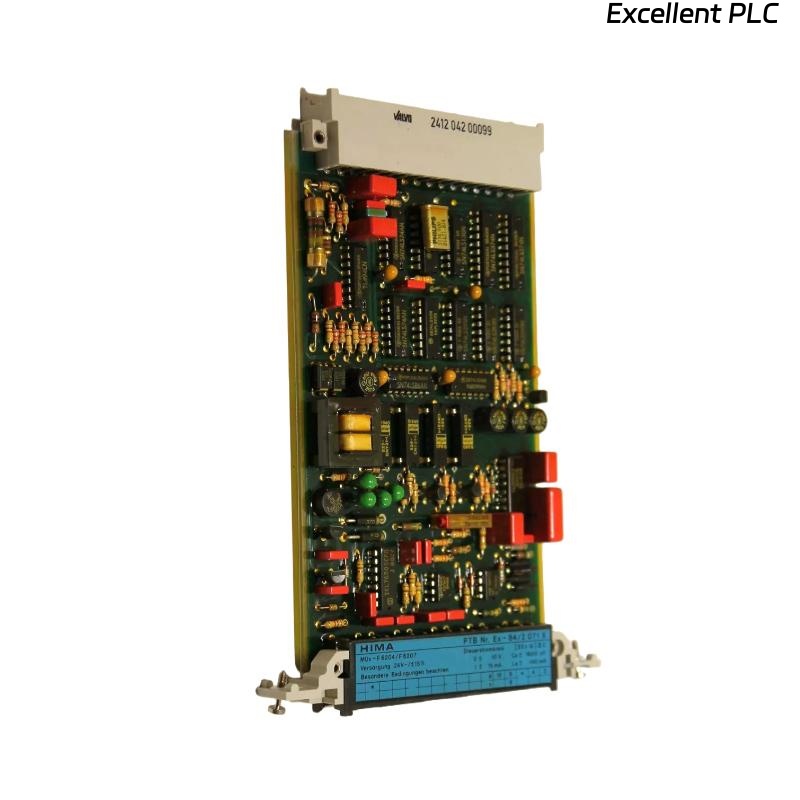

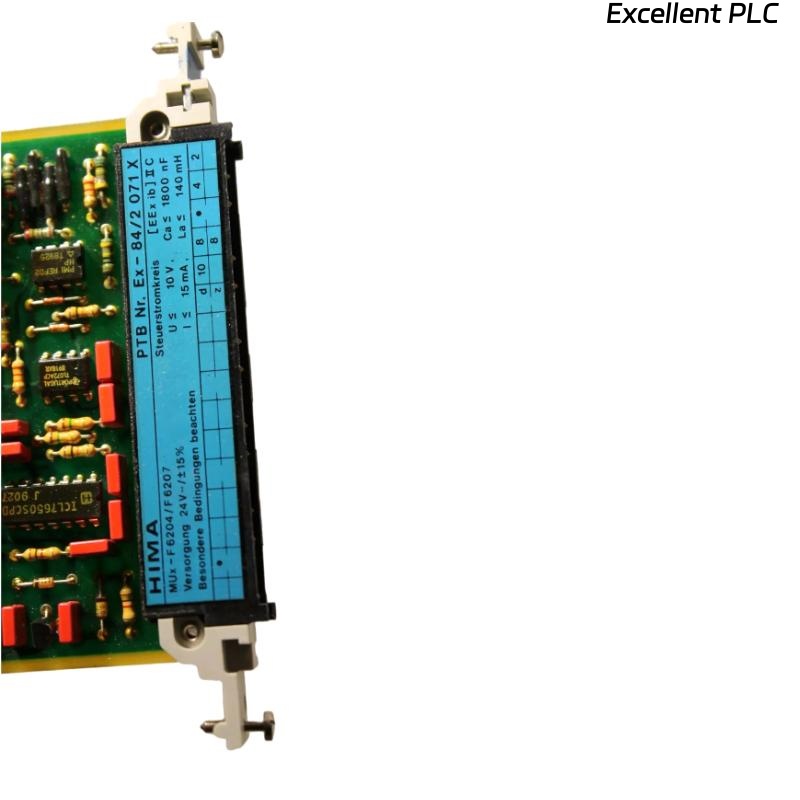

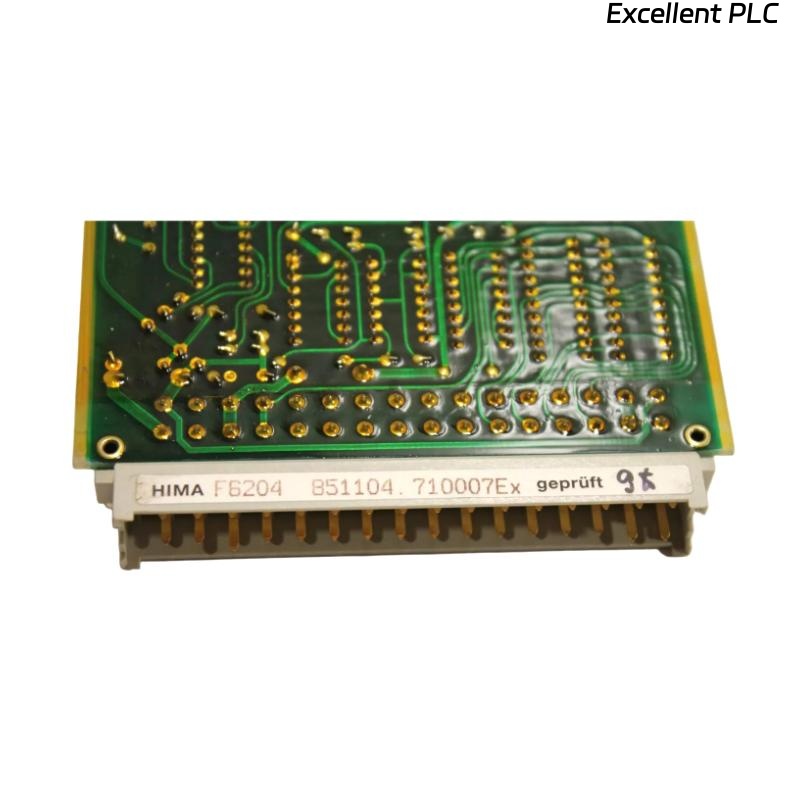

The HIMA F6204 Analog Input Module is a high-reliability analog input module designed for use in safety-related and mission-critical automation systems. As part of HIMA’s trusted safety instrumented system (SIS) portfolio, the F6204 is engineered to process multiple types of analog signals with accuracy, stability, and diagnostic capability. It is widely used in industries where safety, precision, and availability are essential, including oil and gas, petrochemical, power generation, and process automation.

By converting and monitoring analog signals such as temperature, pressure, flow, or level, the F6204 acts as the bridge between field instrumentation and the central safety controller. It ensures that accurate process values are continuously delivered for logic execution and protective action.

Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Analog Input Module |

| Input Channels | 8 isolated analog input channels |

| Supported Input Types | 4–20 mA, 0–20 mA, 0–10 V, ±10 V |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Input Impedance | >250 Ω (current inputs), >1 MΩ (voltage inputs) |

| Isolation | Galvanic isolation between channels and system |

| Diagnostics | Channel fault detection, open/short circuit, out-of-range monitoring |

| Safety Standard Compliance | IEC 61508, SIL 3 certified |

| Operating Temperature Range | -20 °C to +60 °C |

| Power Consumption | <5 W |

| Dimensions (H × W × D) | 160 × 25 × 120 mm |

| Weight | 0.35 kg |

| Mounting | DIN rail or rack-based installation |

Product Applications

The F6204 Analog Input Module is widely applied in various process industries that demand safe and accurate measurement of analog signals:

-

Oil & Gas Industry: Monitoring pressure, temperature, and flow transmitters for emergency shutdown systems.

-

Petrochemical Plants: Integration with safety logic solvers for high-integrity pressure protection systems (HIPPS).

-

Power Generation: Monitoring turbine parameters such as vibration, temperature, and steam pressure.

-

Chemical Industry: Reliable measurement of process parameters to ensure product quality and plant safety.

-

Energy & Utilities: Integration into distributed safety systems to monitor boiler and fuel systems.

-

Pharmaceutical Manufacturing: Precision measurement of process values to comply with strict safety and quality standards.

Product Advantages

-

High Safety Compliance: SIL 3 certified, ensuring compliance with international safety standards.

-

Versatile Signal Support: Compatible with both current and voltage input types for flexible field device integration.

-

Robust Diagnostics: Built-in diagnostics detect wiring faults, sensor failures, and signal deviations in real-time.

-

Isolation & Noise Immunity: Galvanic isolation prevents interference and ensures signal integrity in harsh industrial environments.

-

Compact Design: Slim form factor allows for high-density installation in control cabinets.

-

Reliability & Availability: Designed for continuous operation in critical safety applications with redundant system compatibility.

FAQ

-

What types of input signals can the F6204 process?

The module supports both current (4–20 mA, 0–20 mA) and voltage (0–10 V, ±10 V) input signals. -

Does the F6204 provide galvanic isolation between channels?

Yes, the module includes galvanic isolation between individual channels and the system bus. -

What is the resolution of the analog input channels?

Each input channel provides a resolution of 16 bits, ensuring precise measurement. -

How does the F6204 handle diagnostic monitoring?

The module detects wiring errors, sensor failures, out-of-range values, and short/open circuits. -

Is the F6204 certified for safety applications?

Yes, it is SIL 3 certified according to IEC 61508 standards. -

Can the module operate in redundant system architectures?

Yes, it is designed for integration into redundant configurations to enhance system reliability. -

What is the maximum number of analog channels supported per module?

The F6204 provides up to 8 isolated analog input channels. -

How does the module ensure accuracy in harsh environments?

With galvanic isolation, filtering, and robust construction, it maintains ±0.1% accuracy under demanding conditions. -

What kind of fault detection is available on each channel?

Each channel can detect open-circuit, short-circuit, and input out-of-range conditions. -

Can the F6204 be integrated into non-HIMA systems?

While optimized for HIMA controllers, the F6204 can interface with other systems via standard communication protocols.

Recommended Related Models (Same Series or Similar)

| Model Number | Description | Channels | Signal Type | Weight |

|---|---|---|---|---|

| F6217 | Analog Output Module | 8 | Current/Voltage output | 0.36 kg |

| F6220 | Digital Input Module | 16 | 24 V DC inputs | 0.32 kg |

| F6221 | Digital Output Module | 16 | Relay/Transistor outputs | 0.34 kg |

| F7105 | Counter Module | 4 | Pulse inputs | 0.33 kg |

| F8650X | Communication Processor Module | – | Network/Fieldbus | 0.40 kg |

| F7130 | Temperature Input Module | 8 | RTD/Thermocouple | 0.35 kg |

Recommended Popular Models (Same Brand, HIMA)

| Model Number | Description | Application Area | Weight |

|---|---|---|---|

| F8650E | Communication Interface Module | System networking and redundancy | 0.40 kg |

| F3236 | Digital Input Module | High-density input applications | 0.34 kg |

| F3330 | Digital Output Module | Actuator and solenoid control | 0.35 kg |

| F7101 | Analog Input Module (High Precision) | Safety-critical analog measurements | 0.36 kg |

| F8627X | CPU Module | HIMax safety controller core | 0.42 kg |

| F7553 | Power Supply Module | Reliable power supply for I/O modules | 0.50 kg |

Excellent PLC

Excellent PLC