| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

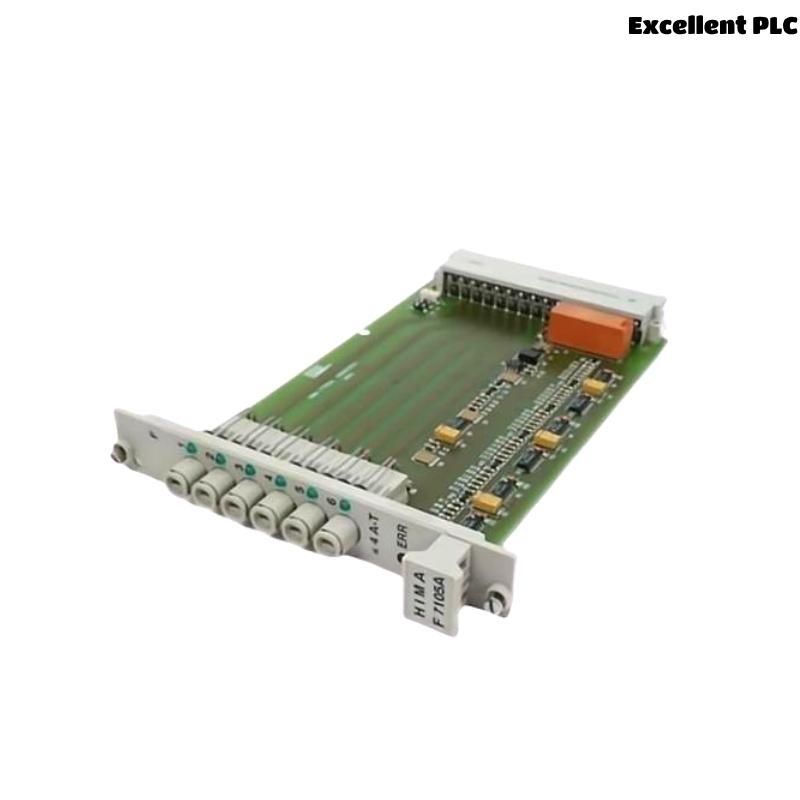

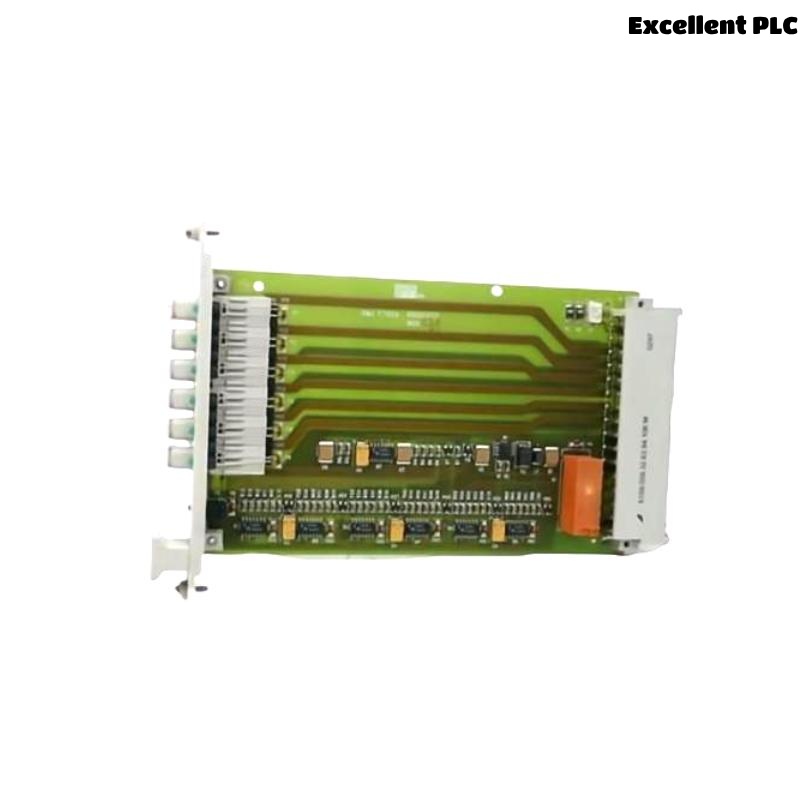

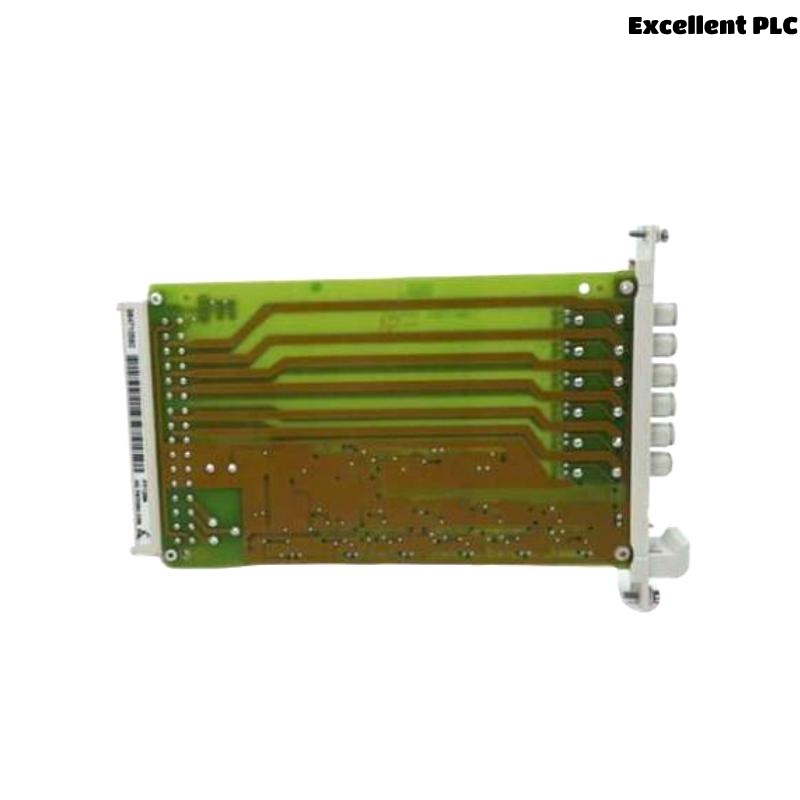

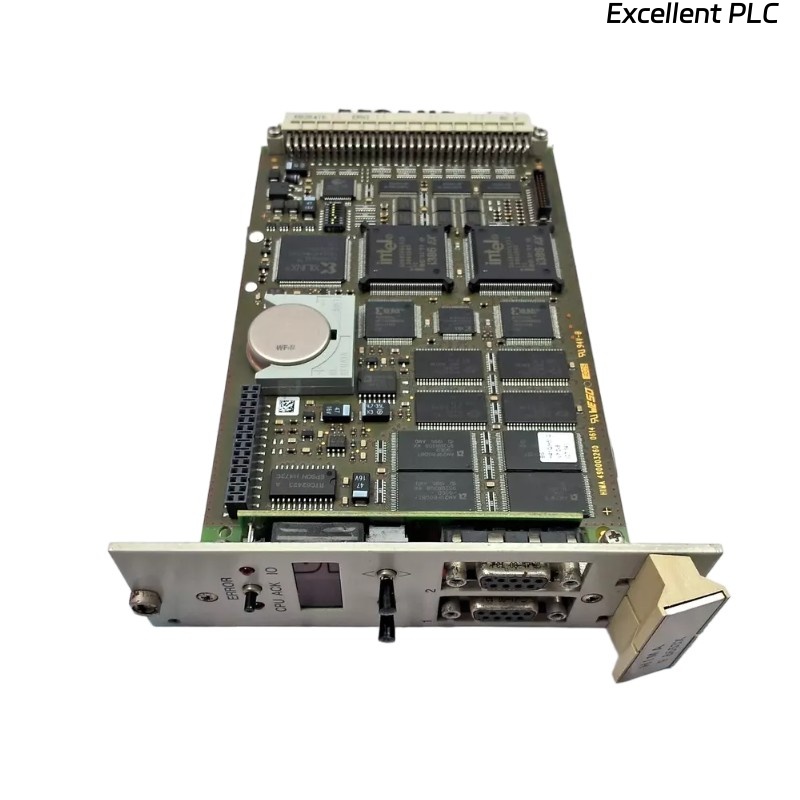

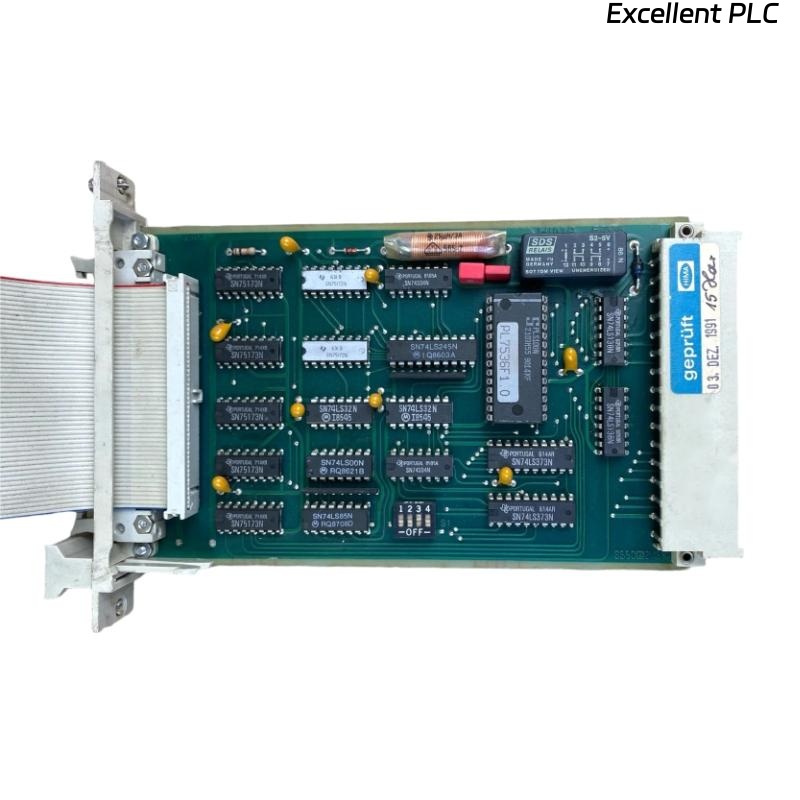

The HIMA F7105A Safety-Related Application Module is an essential component designed to support high-integrity safety functions in industrial control and automation systems. Developed by HIMA, a leader in safety technology, the F7105A module provides reliable, real-time processing of safety-critical signals to ensure plant and personnel protection.

This module is engineered to be integrated into the HIMA safety system platforms, such as the HIMax or HiQuad series, enabling flexible and scalable safety architectures. It is widely used in industries where functional safety standards such as IEC 61508 and IEC 61511 are mandatory. The F7105A handles complex safety logic, input/output monitoring, and communication tasks, ensuring that critical safety actions are executed promptly and reliably.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | HIMA F7105A |

| Function | Safety-Related Application Module |

| Safety Integrity Level (SIL) | SIL 3 (according to IEC 61508) |

| Dimensions (HxWxD) | 25 x 127 x 203 mm |

| Weight | 0.25 kg |

| Power Supply | 24 V DC ± 20% |

| Communication Interfaces | PROFIBUS, Ethernet (optional) |

| Input Channels | Multiple configurable digital inputs |

| Output Channels | Multiple configurable digital outputs |

| Operating Temperature Range | -20°C to +60°C |

| Certification | ATEX, IECEx, SIL certified |

| Mounting | DIN rail or panel mount |

| Response Time | < 10 ms |

| Diagnostics | Built-in self-test and fault diagnostics |

Product Applications

The HIMA F7105A module is widely adopted across various industries requiring stringent safety measures, including:

-

Oil and Gas Industry: Protecting pipelines, refineries, and offshore platforms by managing emergency shutdown systems (ESD) and fire and gas detection.

-

Chemical and Petrochemical Plants: Controlling safety interlocks and process shutdown to prevent hazardous incidents.

-

Power Generation: Safeguarding turbines, generators, and electrical systems through dependable safety logic and fault monitoring.

-

Pharmaceutical Manufacturing: Ensuring process safety and compliance with rigorous regulations through automated safety systems.

-

Transportation Infrastructure: Managing safety functions in railways, subways, and airports.

-

Heavy Industry and Manufacturing: Protecting machinery and personnel by enforcing safety protocols in production lines.

Product Advantages

-

High Safety Integrity: Certified to SIL 3, the F7105A meets the most demanding functional safety requirements.

-

Robust Construction: Designed to operate reliably under industrial environmental stresses, including temperature extremes and electrical disturbances.

-

Flexible Integration: Supports multiple communication protocols for easy connection with various control and safety systems.

-

Scalable Architecture: Fits seamlessly into small to large safety system configurations, adaptable to evolving plant requirements.

-

Fast Response Time: Ensures safety-critical events are detected and acted upon within milliseconds.

-

Comprehensive Diagnostics: Facilitates predictive maintenance and rapid troubleshooting via built-in self-tests and fault reporting.

-

Ease of Installation: Standard DIN rail or panel mounting simplifies system setup and upgrades.

-

Proven Reliability: Backed by decades of experience from HIMA, a trusted name in safety automation.

Frequently Asked Questions (FAQ)

-

What safety integrity level does the HIMA F7105A support?

It is certified for SIL 3, ensuring compliance with high safety standards. -

Which communication protocols does the module support?

It supports PROFIBUS and optionally Ethernet interfaces. -

What are the power supply requirements?

The module operates on 24 V DC with ±20% tolerance. -

Can the F7105A module be used in hazardous environments?

Yes, it has ATEX and IECEx certifications for hazardous area use. -

What is the typical response time of this module?

The response time is under 10 milliseconds. -

How is the module installed?

It can be mounted on a DIN rail or panel. -

Does the module include self-diagnostic features?

Yes, it includes built-in self-tests and fault diagnostics. -

What is the operating temperature range?

The module works reliably between -20°C and +60°C. -

Is this module compatible with other HIMA safety systems?

Yes, it is designed to integrate with HIMax, HiQuad, and other HIMA platforms. -

What industries typically use the F7105A?

It is widely used in oil & gas, chemical, power generation, pharmaceuticals, transportation, and heavy industry sectors.

Recommended Related Models

| Model | Function | Dimensions (mm) | Weight (kg) | Notes |

|---|---|---|---|---|

| F7100A | Safety CPU Module | 130 x 100 x 25 | 0.38 | Core processor module |

| F7101A | Safety Input Module | 130 x 80 x 25 | 0.35 | Digital input channels |

| F7102A | Safety Output Module | 130 x 80 x 25 | 0.36 | Relay output channels |

| F7103A | Analog Safety Module | 130 x 100 x 25 | 0.40 | Analog input/output processing |

| F7104A | Communication Interface Module | 130 x 100 x 25 | 0.42 | PROFIBUS/Ethernet communication |

| F7106A | Redundancy Module | 130 x 100 x 30 | 0.45 | Provides system redundancy |

Popular HIMA Models from the Same Brand

| Model | Function | Dimensions (mm) | Weight (kg) | Application Focus |

|---|---|---|---|---|

| HIMax | Safety Controller | Variable | 1.5 – 5 | Modular safety control system |

| HiQuad | Safety Controller | Variable | 1.5 – 6 | High-performance safety platform |

| F7220 | Safety CPU Module | 130 x 120 x 30 | 0.50 | High-density safety CPU |

| F7300 | Safety Logic Solver | 140 x 110 x 40 | 0.65 | Advanced safety logic processing |

| F7400 | Safety Relay Module | 120 x 90 x 25 | 0.45 | Safety output relays |

| F7500 | Safety Communication Module | 130 x 100 x 30 | 0.48 | Network and fieldbus communication |

Excellent PLC

Excellent PLC