| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Technical Specifications

Product Introduction

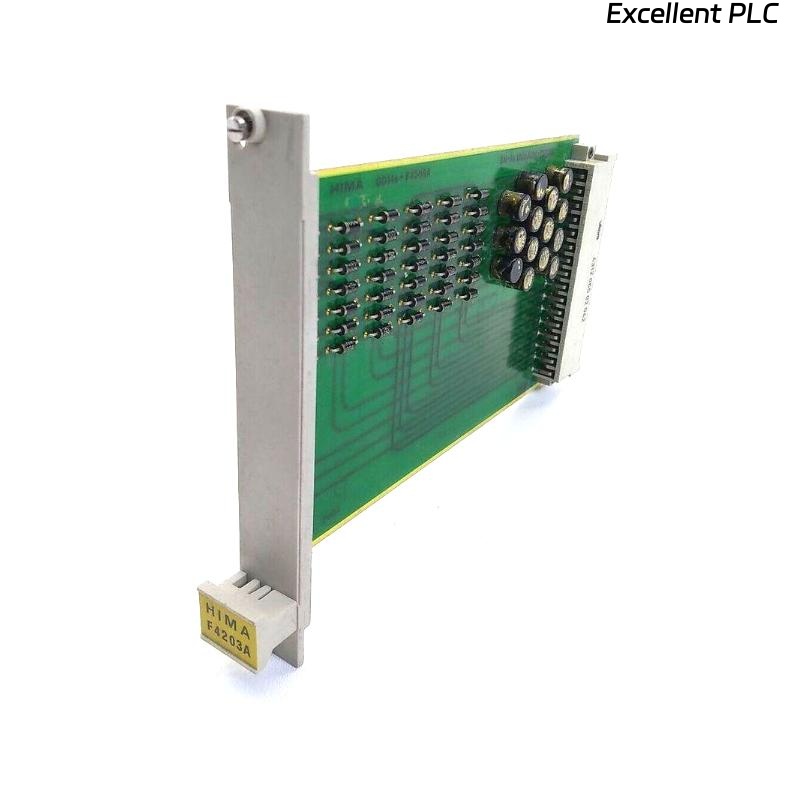

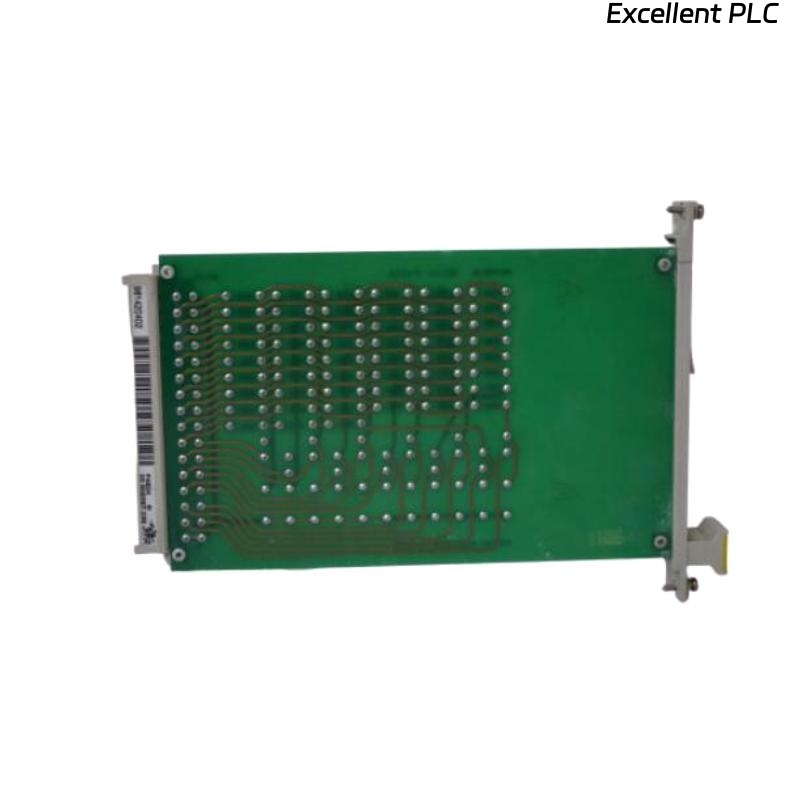

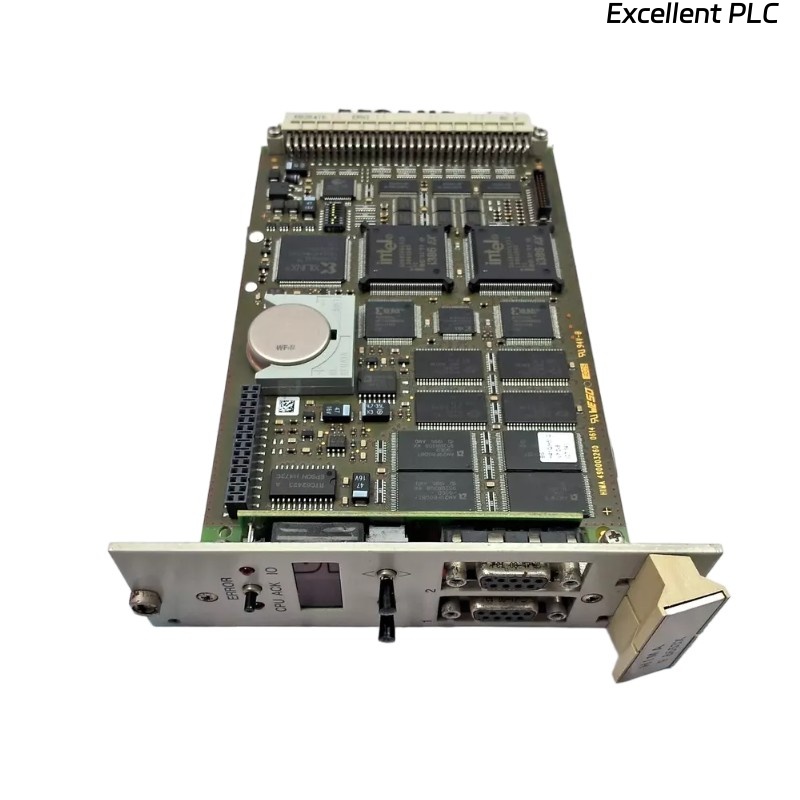

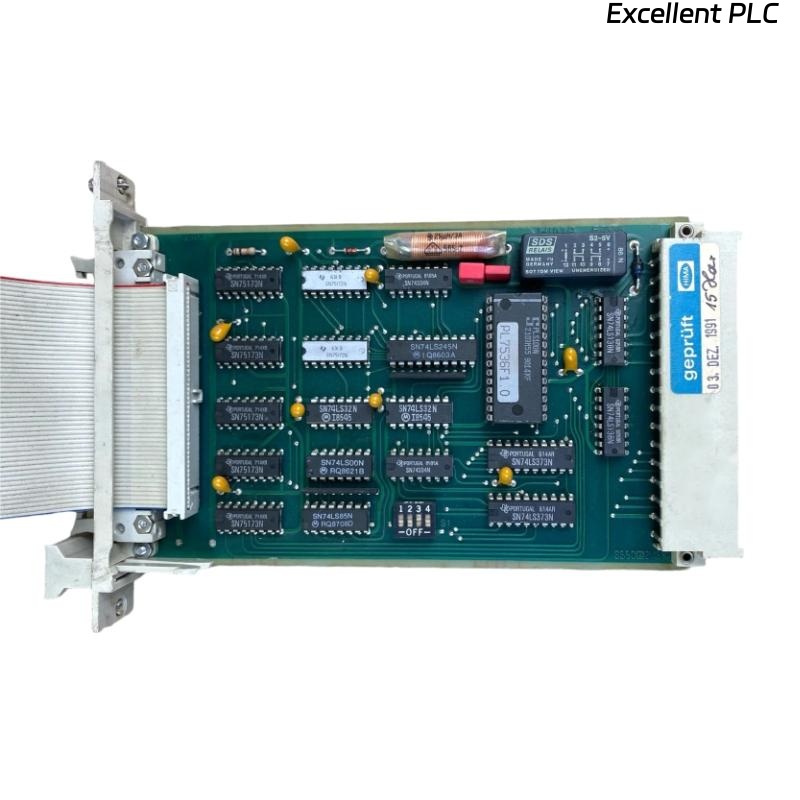

The HIMA F7126A is a safety-critical component designed for industrial automation and process control systems. It forms part of HIMA’s reliable safety solutions that provide high availability, performance, and scalability for complex safety tasks. With its advanced technology and robust design, the HIMA F7126A is an essential device for ensuring process safety and safeguarding personnel, equipment, and assets in demanding environments.

This model is typically used in applications requiring high levels of functional safety, such as oil and gas, chemical processing, and power generation sectors. It integrates seamlessly with other components in a safety instrumented system (SIS) and provides a compact and efficient solution for safety-critical control functions.

Product Applications

-

Process Industry: To ensure the safe operation of production processes, such as in oil and gas extraction, refining, and petrochemical plants.

-

Energy Sector: For power generation plants, ensuring that machinery operates within safe parameters and preventing catastrophic failures.

-

Chemical Processing: The device is used to monitor hazardous processes and prevent dangerous conditions in chemical reactors and distillation columns.

-

Automated Manufacturing Systems: To guarantee safe production lines, protecting both workers and machinery from failures.

-

Environmental Control: To monitor and control systems related to environmental safety, such as waste management or pollution control processes.

Advantages of HIMA F7126A

-

Compact Design: The small form factor makes the F7126A ideal for space-constrained installations while maintaining high performance.

-

High Availability: Built for demanding industrial environments, ensuring minimal downtime and high reliability.

-

Flexible Integration: Easily integrates with existing safety systems, providing scalability and adaptability.

-

Robust Performance: Designed to operate in a wide range of temperatures and conditions, from extreme heat to freezing temperatures.

-

Cost-Efficient Safety: Provides a cost-effective solution for high-performance safety control without compromising on reliability.

FAQ

**Q1: **What is the typical use of the HIMA F7126A?

A1: The HIMA F7126A is used in safety instrumented systems to monitor and control critical safety functions in industries like oil & gas, chemical processing, and power generation.

**Q2: **Can the F7126A be integrated with other HIMA safety systems?

A2: Yes, the HIMA F7126A is designed for easy integration with other HIMA products, enabling scalable and flexible safety solutions across various industrial applications.

**Q3: **What is the voltage requirement for the F7126A?

A3: The HIMA F7126A operates on a 24 V DC voltage supply, ensuring compatibility with standard industrial power systems.

**Q4: **What are the operating temperature conditions of the F7126A?

A4: The device can function in a temperature range from -20°C to 60°C, making it suitable for a wide range of industrial environments.

**Q5: **How much power does the HIMA F7126A consume?

A5: The power consumption of the F7126A is 5 W, which is efficient for its functionality in industrial applications.

**Q6: **What industries benefit from using the HIMA F7126A?

A6: The HIMA F7126A is commonly used in industries such as oil and gas, chemical processing, power generation, and manufacturing.

**Q7: **What is the weight of the HIMA F7126A?

A7: The device weighs 0.85 kg, making it lightweight and easy to install.

**Q8: **What kind of maintenance does the F7126A require?

A8: The F7126A requires minimal maintenance, but it should be inspected regularly as part of the system’s safety checks to ensure optimal performance.

**Q9: **Is the HIMA F7126A compliant with safety standards?

A9: Yes, it meets international safety standards for functional safety, ensuring it can be used in safety instrumented systems (SIS) for critical applications.

**Q10: **What is the life expectancy of the HIMA F7126A?

A10: The life expectancy of the HIMA F7126A is typically between 5 to 10 years, depending on environmental conditions and the level of usage.

Recommended Models from the Same Series or Related Models

| Model | Description | Voltage | Weight | Applications |

|---|---|---|---|---|

| F7126B | Advanced version with more I/O capabilities | 24 V DC | 0.6 kg | Heavy-duty industries, automation |

| F7127A | Dual-channel version for redundancy | 24 V DC | 0.55 kg | Process safety, critical control systems |

| F7128A | Modular system for large-scale installations | 24 V DC | 0.7 kg | Large factories, integrated safety systems |

| F7129A | Safety controller with advanced diagnostics | 24 V DC | 0.65 kg | Chemical plants, energy facilities |

| F7130A | High-performance control unit | 24 V DC | 0.75 kg | Power generation, industrial monitoring |

| F7131A | Explosion-proof version for hazardous areas | 24 V DC | 0.8 kg | Oil & gas, offshore platforms |

6 Popular Models from HIMA

| Model | Description | Voltage | Weight | Applications |

|---|---|---|---|---|

| F60 | High availability, real-time monitoring system | 24 V DC | 1.2 kg | Chemical plants, process control |

| F35 | Low-cost solution for small-scale applications | 24 V DC | 0.45 kg | Small manufacturing units |

| F33 | Controller for medium-sized installations | 24 V DC | 1.0 kg | Automation, factory production |

| F100 | Comprehensive process control system | 24 V DC | 2.5 kg | Industrial safety, power plants |

| F200 | Scalable safety system for large operations | 24 V DC | 3.0 kg | Mining, oil & gas, power generation |

| F120 | Modular safety controller for multi-unit setups | 24 V DC | 1.8 kg | Manufacturing, assembly lines |

Excellent PLC

Excellent PLC