| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

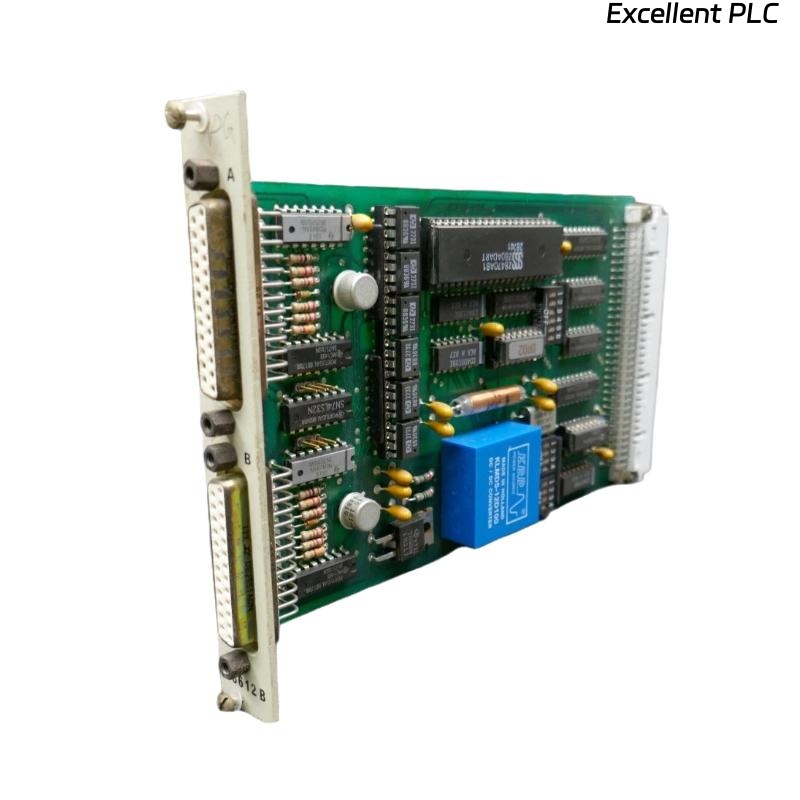

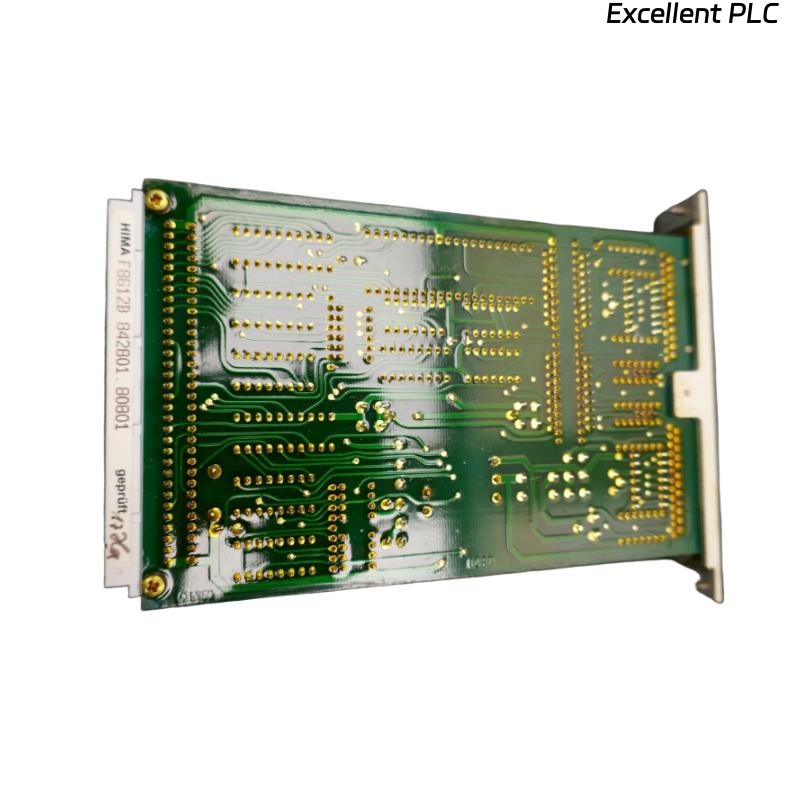

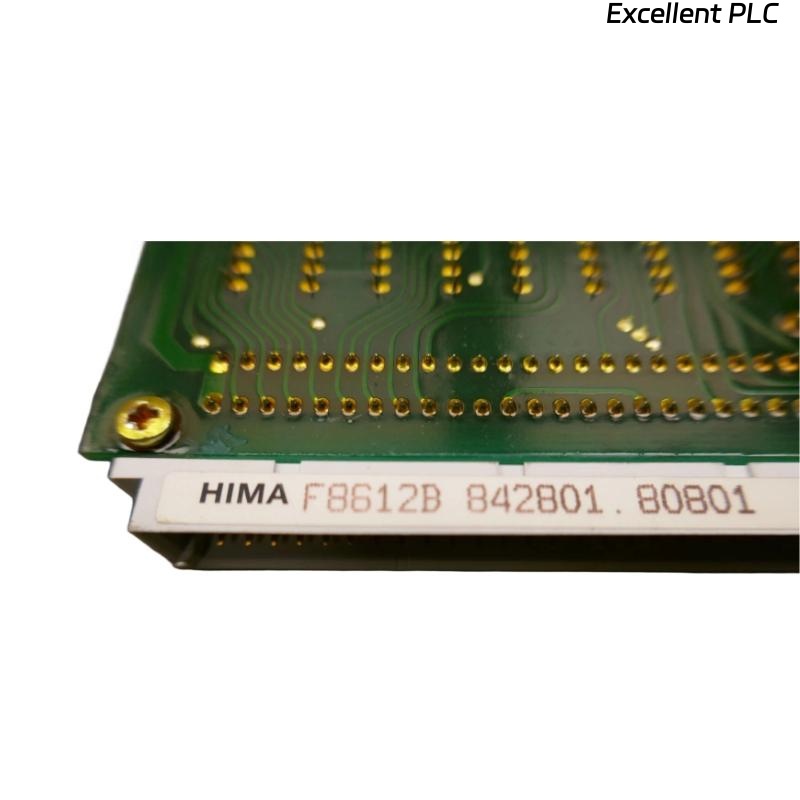

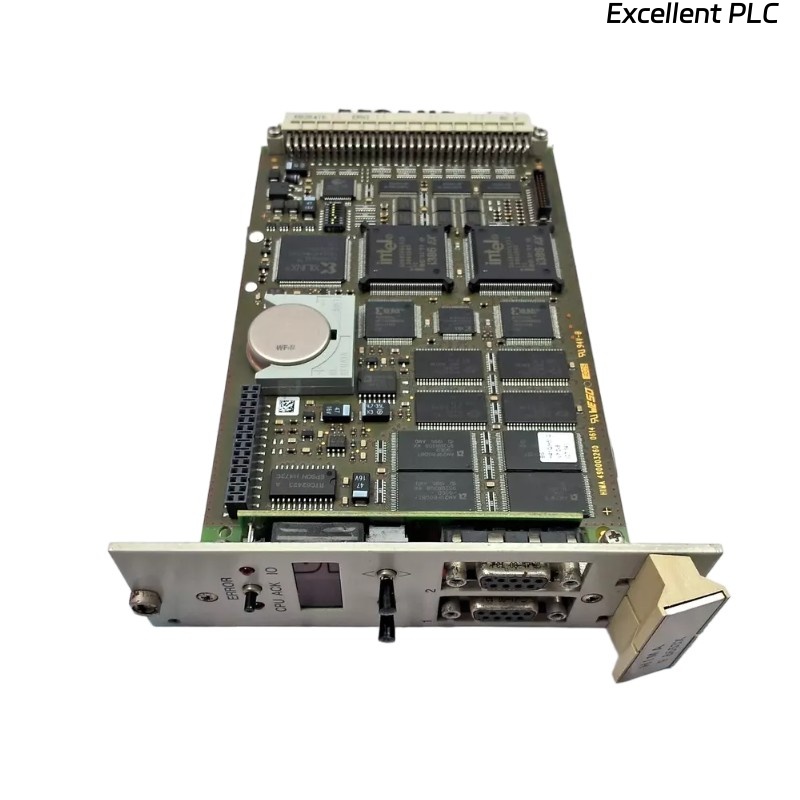

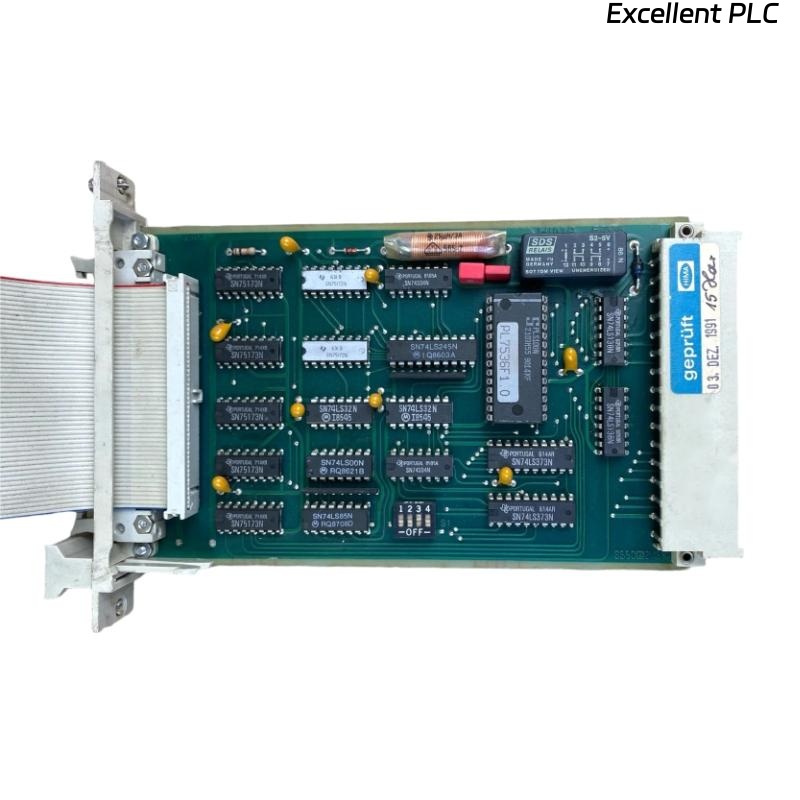

The HIMA F8612B Printed Circuit Board (PCB) Module is an advanced safety and control module developed for integration into HIMA’s trusted safety and automation platform. As part of the highly reliable HIMA HIMax and HIQuad systems, the F8612B is engineered to manage signal processing, control logic, and safety-critical communication in demanding industrial applications.

This module leverages robust printed circuit board technology to provide stability, high-speed signal handling, and precise fault diagnostics. The F8612B is widely deployed in safety instrumented systems (SIS), emergency shutdown (ESD) applications, and process automation environments where reliability and fault tolerance are paramount.

Product Parameters

| Parameter | Description |

|---|---|

| Product Model | HIMA F8612B Printed Circuit Board Module |

| Function | Signal processing and safety control module |

| Input/Output Capacity | Up to 16 configurable digital or analog channels |

| Processing Capability | Real-time signal processing with fault-tolerant design |

| Communication Interfaces | HIMA system bus, Modbus, Profibus, Ethernet (depending on rack integration) |

| Power Supply | 24 VDC (nominal) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Cooling Method | Natural convection or rack-based forced air |

| Diagnostic Features | Built-in self-test, error logs, and LED indicators for fault isolation |

| Redundancy Support | Yes, supports hot-standby redundancy |

| Mounting Type | Rack-mounted PCB module |

| Dimensions (H × W × D) | 180 × 30 × 250 mm |

| Weight | 0.18 kg |

Product Applications

The HIMA F8612B Module is applied in a wide variety of critical industries where safety and operational continuity cannot be compromised. Key applications include:

-

Oil & Gas: Emergency shutdown (ESD), blowout preventer monitoring, and pipeline interlock systems.

-

Petrochemical & Chemical Plants: Process shutdown systems, reactor control, and hazardous material safety management.

-

Power Generation: Turbine control, boiler safety interlocks, and balance-of-plant system monitoring.

-

Transportation Systems: Rail signaling, safety interlocking, and industrial vehicle monitoring systems.

-

Manufacturing: Plant automation, machinery safety interlocks, and integrated safety controls.

-

Renewable Energy: Wind farm safety control, solar power plant safety, and electrical grid protection.

Product Advantages

-

High Reliability: Built with industrial-grade PCB technology for long-term stable operation.

-

Comprehensive Diagnostics: Integrated self-testing and channel fault detection enable rapid troubleshooting.

-

Safety Compliance: Designed to meet IEC 61508 SIL certification requirements for safety instrumented systems.

-

Flexible I/O Configuration: Supports both analog and digital signals for a wide range of applications.

-

Redundancy Support: Enables hot-standby configurations, ensuring zero downtime during module replacement.

-

Seamless Integration: Fully compatible with HIMA safety systems and other automation infrastructure.

-

Compact Design: Space-efficient rack-mounted module that supports high-density installations.

FAQ

-

What types of signals can the F8612B handle?

The module supports both digital and analog input/output channels, configurable depending on system requirements. -

Does the module support redundant system architecture?

Yes, it fully supports hot-standby redundancy, ensuring uninterrupted operation in case of a primary module failure. -

How are diagnostics performed in the F8612B?

The module performs continuous self-tests, error logging, and uses LED indicators for real-time fault detection. -

Can the F8612B be integrated into existing HIMA safety systems?

Yes, it is fully compatible with HIMax and HIQuad platforms, as well as selected legacy systems. -

What is the maximum number of channels available per module?

The F8612B supports up to 16 configurable I/O channels, adaptable to specific application requirements. -

Does the module support industrial communication protocols?

Yes, through rack integration it supports Modbus, Profibus, Ethernet, and the HIMA proprietary system bus. -

Is the module hot-swappable?

Yes, it can be replaced while the system remains online, minimizing downtime and maintaining process safety. -

How does the module handle fault isolation?

Individual faulty channels are automatically isolated, preventing wider system disruption. -

Can the module be used in SIL-rated safety applications?

Yes, it is designed and certified for use in SIL-rated safety instrumented systems in compliance with IEC 61508. -

What cooling method is recommended for high-density racks?

Natural convection is generally sufficient, but forced air cooling is recommended for dense module configurations.

Recommended Related Models (Same Series or Similar)

| Model | Description |

|---|---|

| HIMA F8611X | Digital Input PCB Module |

| HIMA F8621A | Digital Output Module |

| HIMA F8627X | Communication Interface Module |

| HIMA F7505 | Analog Input PCB Module |

| HIMA F7537 | PCB Module for signal processing |

| HIMA F3330 | Analog Output PCB Module |

Recommended Popular Models (Same Brand – HIMA)

| Model | Description |

|---|---|

| HIMA F7133 | Digital Output Module with advanced diagnostics |

| HIMA F4204 | Analog Input Module for process signals |

| HIMA K9203B | Rack Cooling Fan Unit |

| HIMA F3109 | High-density Analog Input Module |

| HIMA F8627X | Advanced Communication Gateway |

| HIMA F3331 | Analog Output Module with redundancy |

Excellent PLC

Excellent PLC