| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

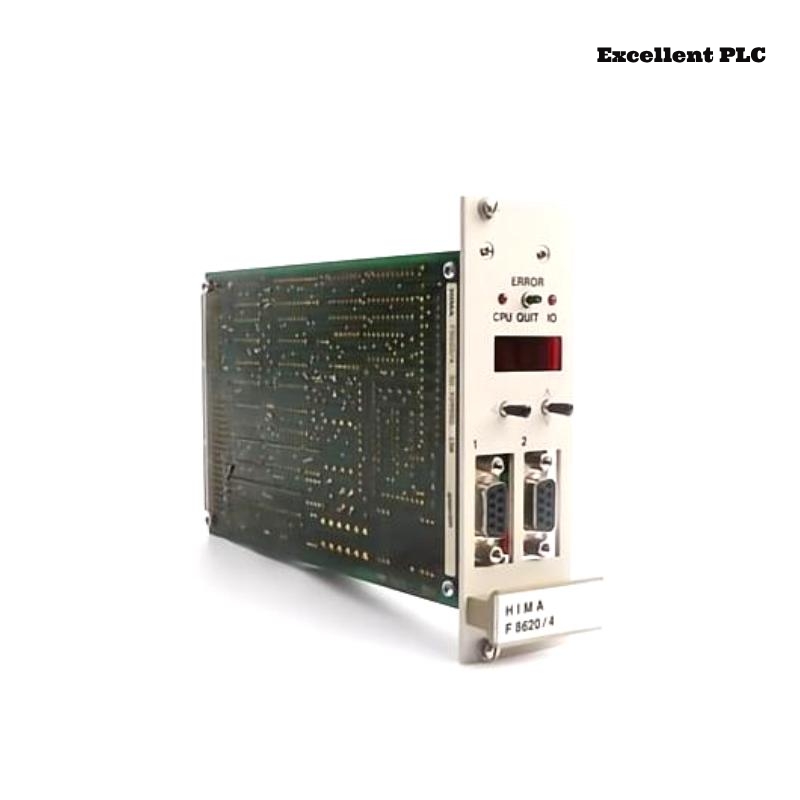

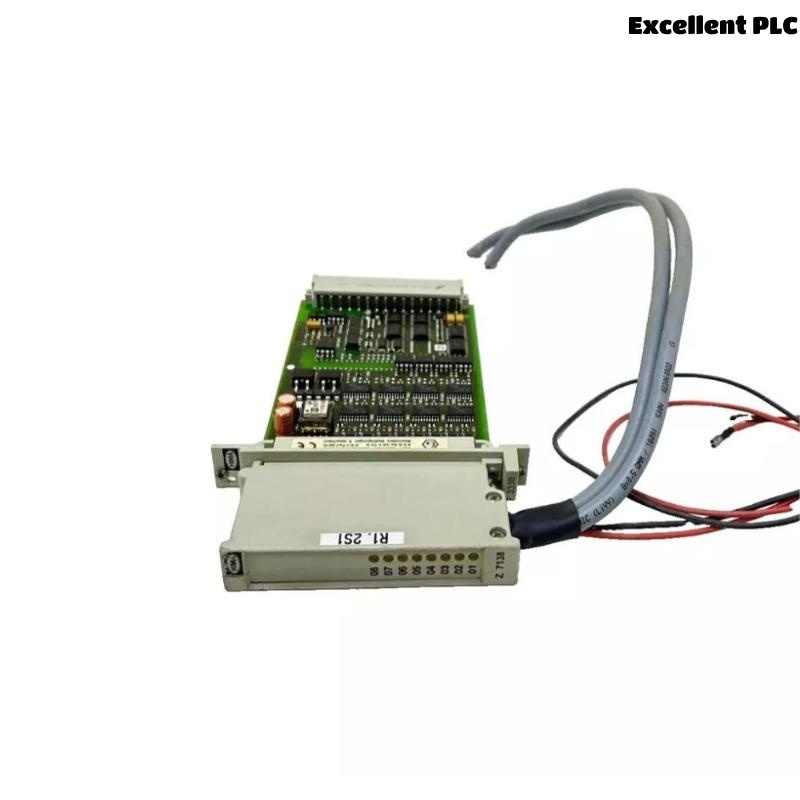

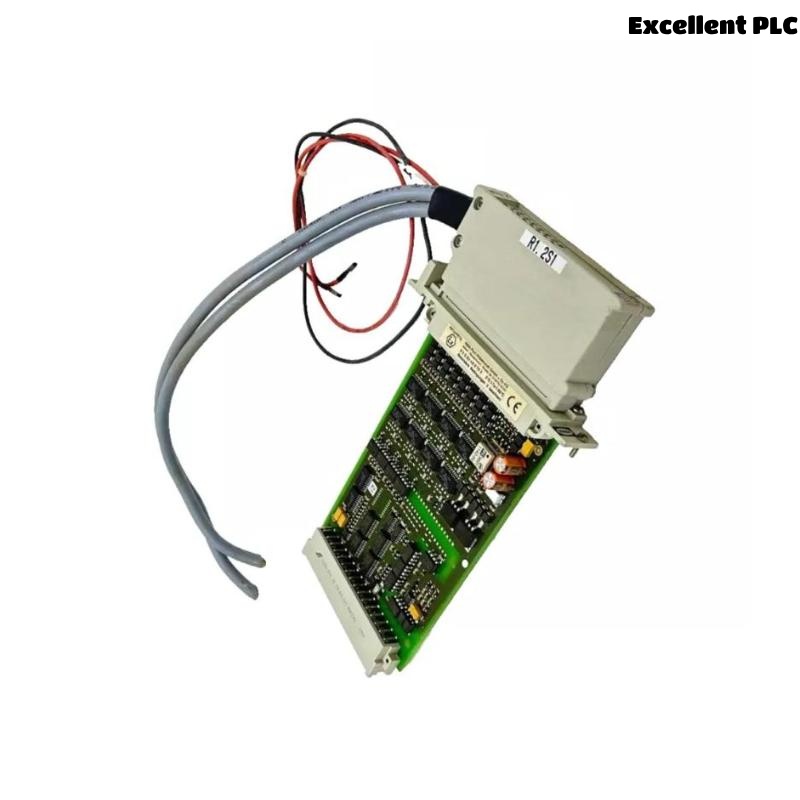

Product Overview

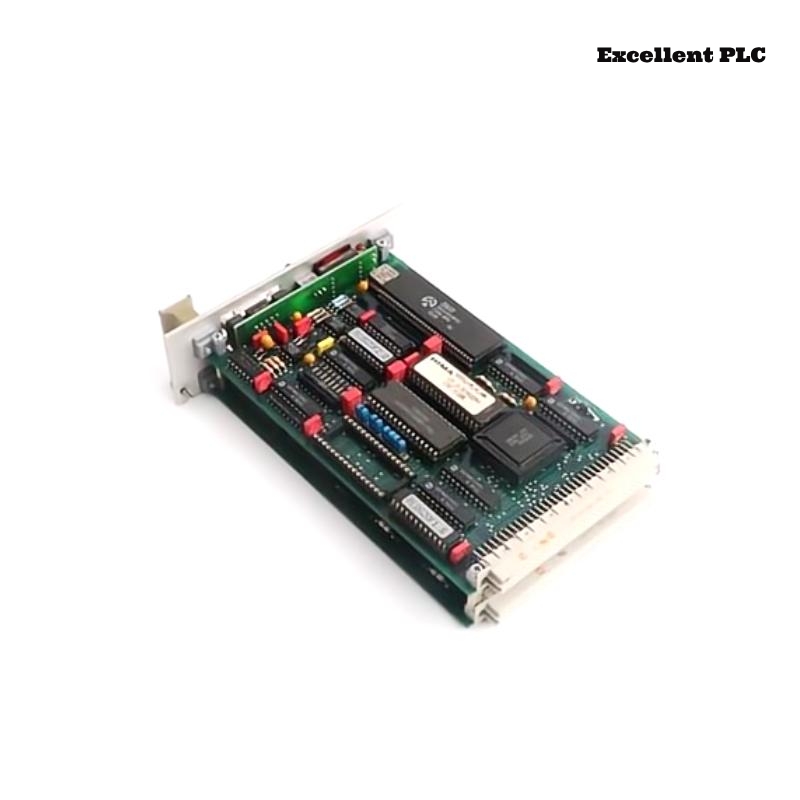

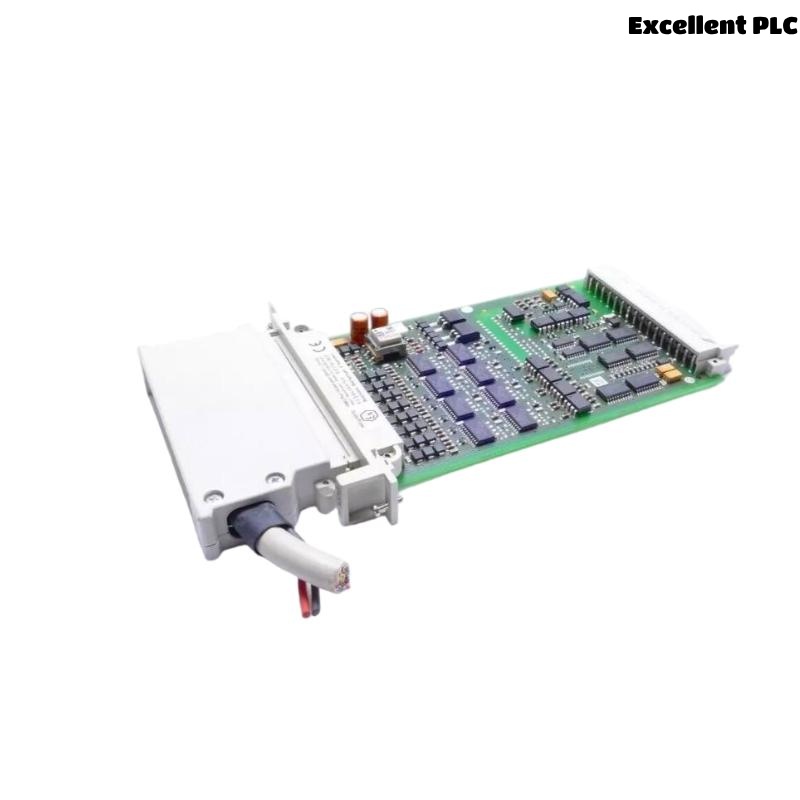

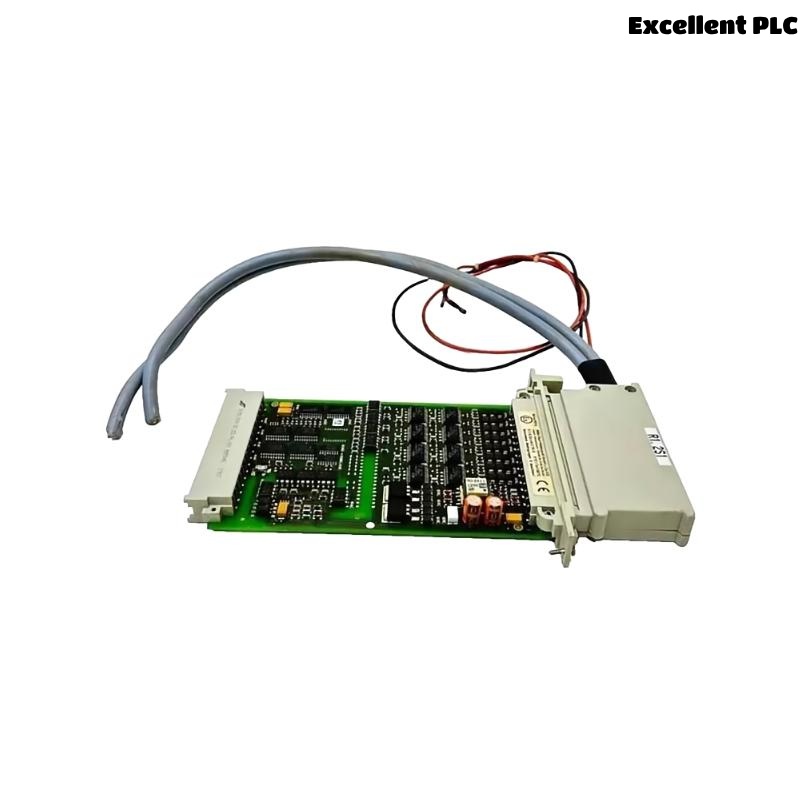

The HIMA F8620/4 CPU Module is a central processing unit designed for use in safety-critical control systems. It is part of HIMA’s modular control system series, providing a robust and highly reliable solution for industries such as chemical processing, oil and gas, energy, and manufacturing. The F8620/4 is designed to meet the stringent requirements of industrial safety applications, ensuring high availability and fault tolerance.

Product Specifications

| Parameter | Value |

|---|---|

| Product Type | CPU Module |

| Model | F8620/4 |

| Operating Voltage | 24 V DC |

| Power Consumption | 20 W |

| CPU Type | ARM-based Processor |

| Communication Interfaces | Ethernet, Serial Ports |

| Redundancy | Hot Standby (optional) |

| Memory | 512 MB RAM, 2 GB Flash |

| Dimensions (L x W x H) | 160 x 100 x 50 mm |

| Weight | 0.45 kg |

| Mounting | DIN Rail |

| Temperature Range | -20°C to +60°C |

| Certifications | SIL 3, IEC 61508, IEC 61511 |

Applications

The HIMA F8620/4 CPU module is widely used in industries that require high-performance and safety-critical control. Its applications include:

-

Process Automation: Used in automated control systems for managing complex industrial processes.

-

Safety Systems: Supports safety-related applications such as emergency shutdown (ESD) and fire and gas detection systems (F&G).

-

Industrial Manufacturing: Implements control solutions for automated production lines and machinery.

-

Energy Industry: Applied in power generation and distribution systems, ensuring safe operation and fault management.

-

Oil & Gas: Critical in managing systems for offshore platforms and refineries, where safety and uptime are paramount.

Advantages

-

High Availability: Built-in redundancy options ensure system availability, even in case of hardware failures.

-

Scalability: The modular design allows easy integration and expansion to accommodate future growth.

-

Safety Integrity Level (SIL): Complies with SIL 3, meeting the highest standards for functional safety in industrial systems.

-

Easy Integration: Supports standard communication protocols, making it compatible with various field devices and control systems.

-

Robust Performance: Provides stable performance under harsh environmental conditions, with a wide operating temperature range and industrial-grade durability.

-

Fault Tolerant: The system is designed for continuous operation with minimal downtime, even during maintenance or when components fail.

-

Efficient Diagnostics: Comprehensive diagnostics and troubleshooting features ensure faster response times and reduced maintenance costs.

Latest News Titles

-

“HIMA F8620/4 CPU Module: Enhancing Industrial Safety Standards”

-

“How HIMA’s F8620/4 Revolutionizes Safety Systems in Critical Industries”

-

“New Developments in HIMA’s F8620/4 CPU: The Future of Process Automation”

-

“Maximizing Uptime with HIMA’s F8620/4 Redundant Control Systems”

-

“Implementing SIL 3 Compliance in the Oil & Gas Sector with HIMA F8620/4”

-

“A Closer Look at the Scalability Features of HIMA’s F8620/4 CPU Module”

-

“HIMA F8620/4: A Game Changer for Energy Sector Control Systems”

-

“How the HIMA F8620/4 Contributes to Safer Manufacturing Environments”

FAQ

-

What is the primary function of the HIMA F8620/4 CPU Module?

-

The F8620/4 CPU module functions as the central processing unit in safety-critical industrial control systems, managing complex automation and safety tasks.

-

-

What industries can benefit from using the HIMA F8620/4?

-

Industries such as chemical processing, oil & gas, power generation, manufacturing, and automotive can all benefit from its reliability and safety features.

-

-

Is the HIMA F8620/4 compatible with other HIMA control modules?

-

Yes, the F8620/4 is part of the HIMA modular system and integrates seamlessly with other HIMA control modules and devices.

-

-

What is the weight of the F8620/4 CPU module?

-

The F8620/4 weighs 0.45 kg.

-

-

Can the F8620/4 be mounted on a DIN rail?

-

Yes, the F8620/4 is designed for easy installation on a DIN rail.

-

-

Does the F8620/4 support redundancy?

-

Yes, the F8620/4 supports optional hot standby redundancy for increased system availability.

-

-

What communication protocols are supported by the F8620/4?

-

The module supports Ethernet and serial communication protocols for seamless integration into existing networks.

-

-

What is the temperature range of the F8620/4?

-

The operating temperature range is from -20°C to +60°C, making it suitable for diverse environments.

-

-

How much memory does the F8620/4 module have?

-

It features 512 MB of RAM and 2 GB of Flash memory.

-

-

Is the F8620/4 certified for safety?

-

Yes, it is certified to SIL 3, and meets IEC 61508 and IEC 61511 standards for functional safety.

Related Models from the Same Series or Related Models

| Model | Product Type | Key Features |

|---|---|---|

| F8620/2 | CPU Module | Lower processing power, suitable for smaller systems. |

| F8620/6 | CPU Module | Higher processing power, ideal for large-scale systems. |

| F8615/4 | Communication Module | Supports network integration, designed for I/O systems. |

| F8625/4 | Backup CPU Module | Provides backup functionality for redundancy setups. |

| F8600/4 | I/O Interface Module | Extends system capability for additional I/O devices. |

| F8610/4 | Power Supply Module | Provides reliable power distribution for F8620 modules. |

| F8605/4 | Safety I/O Module | Designed for integration with SIL-rated safety systems. |

| F8690/4 | Expansion Module | Expands system I/O capabilities for larger installations. |

Popular Models from HIMA

| Model | Product Type | Key Features |

|---|---|---|

| F3300/4 | Safety Controller | Highly modular, designed for complex safety applications. |

| F7200/4 | Safety PLC | Integrated control and safety functionalities in one system. |

| F8800/4 | Control Processor | Designed for large-scale, complex control systems. |

| F4100/4 | Redundant CPU Module | Provides high availability through redundant configurations. |

| F9500/4 | Communication Hub | Centralizes network communication for safety systems. |

| F8100/4 | Process Safety System | Combines safety control with process monitoring capabilities. |

| F7000/4 | Advanced I/O Module | High-density I/O for large-scale safety and control systems. |

| F8000/4 | Monitoring & Control Unit | Designed for real-time monitoring in safety-critical systems. |

Excellent PLC

Excellent PLC