| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

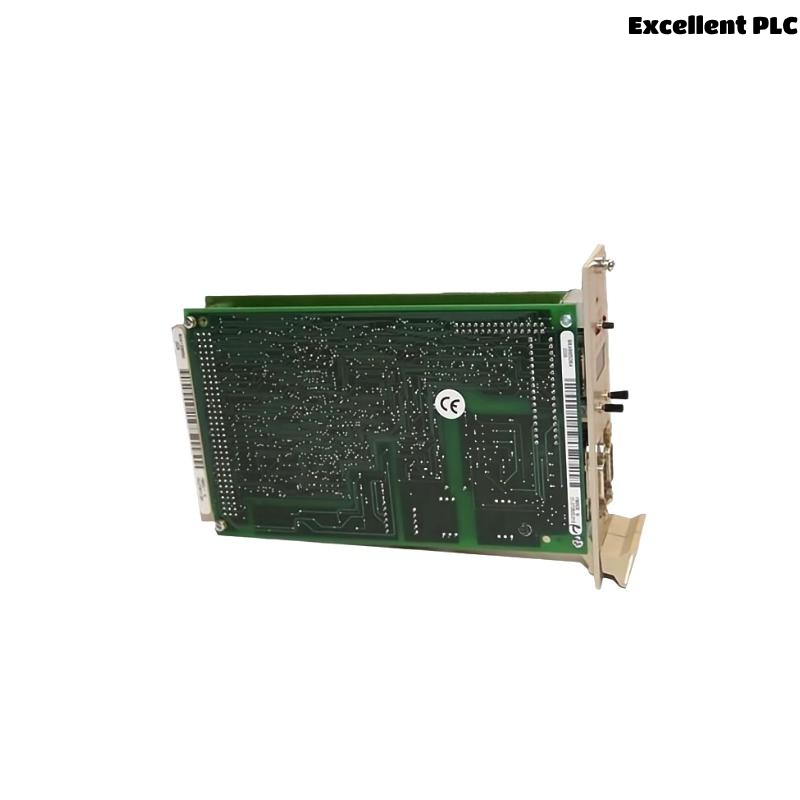

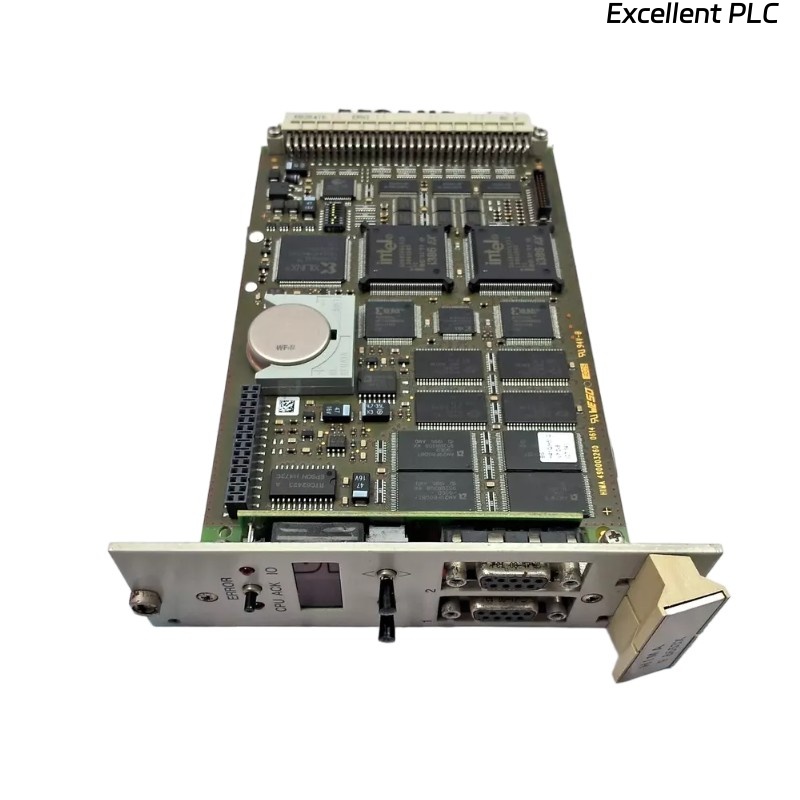

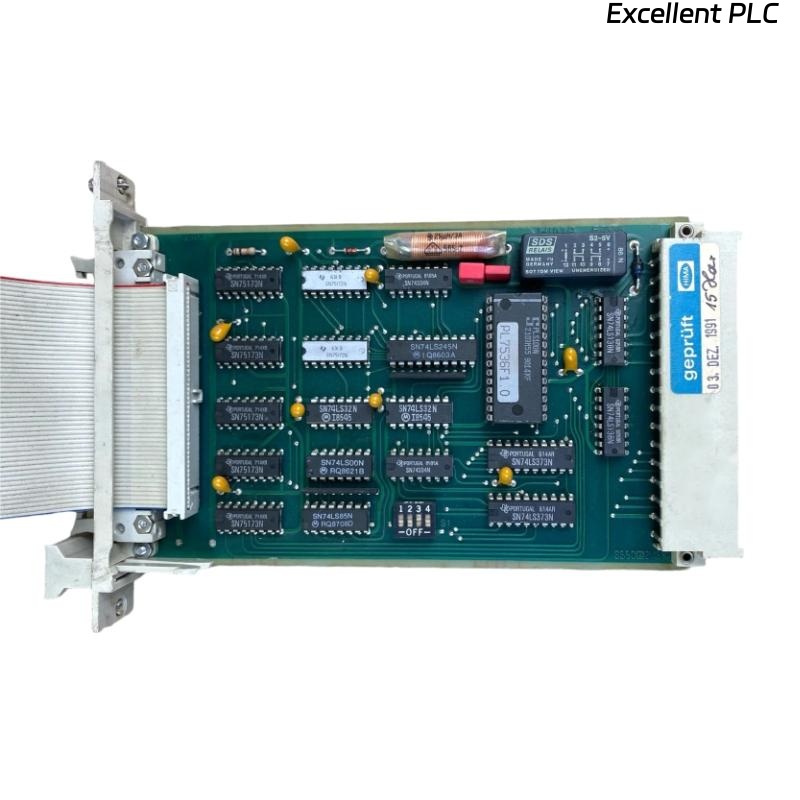

The HIMA F8650E Central Module is a high-performance safety controller core component designed for critical control applications within HIMA’s HIQuad or HIMax safety systems. With its high reliability and fail-safe characteristics, the F8650E is the brain of safety systems used extensively in oil & gas, chemical, energy, and rail industries.

As a redundant-capable central module, the F8650E manages the execution of safety logic, control sequences, and communication between other I/O modules. It integrates real-time diagnostics and failover mechanisms, ensuring continuous system operation in the presence of hardware faults.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | F8650E Central Module |

| System Compatibility | HIQuad / HIMax Safety System |

| Processor | Dual-redundant CPU design for fail-safe operations |

| Internal Memory | 64 MB RAM, 16 MB Flash memory |

| Programming Environment | SILworX / ELOP II Factory |

| Communication Interfaces | Ethernet, RS485, RS232, system bus interfaces |

| Diagnostics | Integrated self-diagnostics and system monitoring |

| Voltage Supply | 24 V DC (redundant power supply supported) |

| Operating Temperature | -20 °C to +60 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | 5% to 95% (non-condensing) |

| Mounting Type | DIN rail mounting |

| Certifications | SIL 3 (IEC 61508), ATEX, CE, TÜV, EN 50156-2 |

| Dimensions (W x H x D) | 257 x 114 x 30 mm |

| Weight | 1.5 kg |

Product Applications

The HIMA F8650E Central Module is tailored for industries where safety is paramount and system availability is non-negotiable. Common application areas include:

-

Oil & Gas Processing Plants

Used in ESD (Emergency Shutdown Systems), BMS (Burner Management Systems), and FGS (Fire & Gas Systems). -

Chemical and Petrochemical Plants

Ensures plant safety by controlling critical processes and reducing downtime through redundancy. -

Power Generation

Plays a key role in turbine protection, boiler management, and balance-of-plant safety applications. -

Railway Automation

Trusted in interlocking systems and level crossing control due to its SIL 3-rated reliability. -

Pharmaceutical Manufacturing

Maintains operational integrity in high-purity and hazardous environments. -

Water Treatment Facilities

Ensures operational continuity and safety compliance in municipal infrastructure.

Product Advantages

-

High Availability Architecture

Supports redundant CPU operation with hot-swappable capabilities, minimizing downtime. -

Certified Safety Compliance

Complies with international safety standards including SIL 3 (IEC 61508), enabling use in critical safety applications. -

Integrated Diagnostics

Real-time error detection and self-testing mechanisms enhance system transparency and reduce troubleshooting time. -

Modular and Scalable

Easily integrates into new or existing HIMA systems with scalable performance for small to large-scale applications. -

Long-Term Support & Lifecycle

HIMA ensures long-term availability and software support, protecting your automation investments. -

Flexible Communication

Offers a wide range of communication interfaces to support legacy and modern system environments.

Frequently Asked Questions (FAQ)

-

What is the primary function of the HIMA F8650E?

It acts as the central processing unit for HIMA safety systems, executing logic and managing system communications. -

Is the F8650E compatible with HIMax and HIQuad systems?

Yes, the F8650E is compatible with both system architectures. -

What safety level does the F8650E comply with?

It is SIL 3 certified according to IEC 61508. -

Does the F8650E support redundant configuration?

Yes, it is designed to operate in a dual-redundant CPU configuration. -

How is the F8650E programmed?

Programming is done through SILworX or ELOP II Factory, depending on the system used. -

What is the power supply requirement?

It requires a 24 V DC supply and supports redundant power connections. -

What communication protocols does the F8650E support?

Ethernet, RS485, RS232, and HIMA’s proprietary system bus protocols. -

Is the module hot-swappable?

Yes, it can be replaced during operation without shutting down the system. -

What are the typical maintenance requirements?

Minimal, due to its self-diagnostic capabilities. Regular firmware updates are recommended. -

Can the F8650E be used in explosive environments?

Yes, it holds ATEX certifications for use in hazardous environments.

Related Models from the Same Series

| Model | Description | Compatibility | SIL Rating |

|---|---|---|---|

| F8650X | Central module with extended diagnostics | HIMax | SIL 3 |

| F8620 | Compact central processing module | HIQuad | SIL 3 |

| F8652 | Redundant processing CPU with faster response time | HIMax | SIL 3 |

| F8657 | Dual-core central module for high-speed applications | HIMax | SIL 3 |

| F8607 | Safety-related CPU for compact systems | HIQuad | SIL 3 |

| F8640 | Modular central module with enhanced memory options | HIMax/HIQuad | SIL 3 |

Popular HIMA Models (Same Brand)

| Model | Function | Application | System |

|---|---|---|---|

| F8621A | Communication processor for safe network linking | Safety Systems | HIQuad |

| F7553 | Digital output module, fail-safe | Field actuator control | HIMax |

| F7133 | Digital input module, SIL 3 rated | Field device input | HIQuad |

| F6705 | Analog input module for temperature sensors | Process monitoring | HIMax |

| F8652X | Redundant CPU module with extended features | Safety-critical systems | HIMax |

| F6503 | Modbus gateway module | Communication integration | HIQuad/HIMax |

Excellent PLC

Excellent PLC