| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

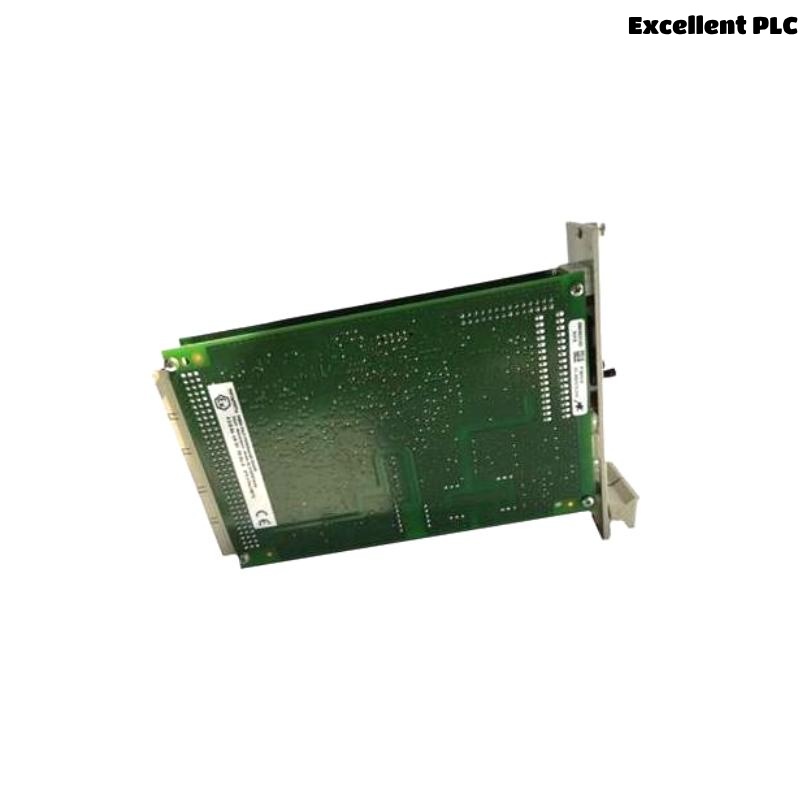

Product Introduction

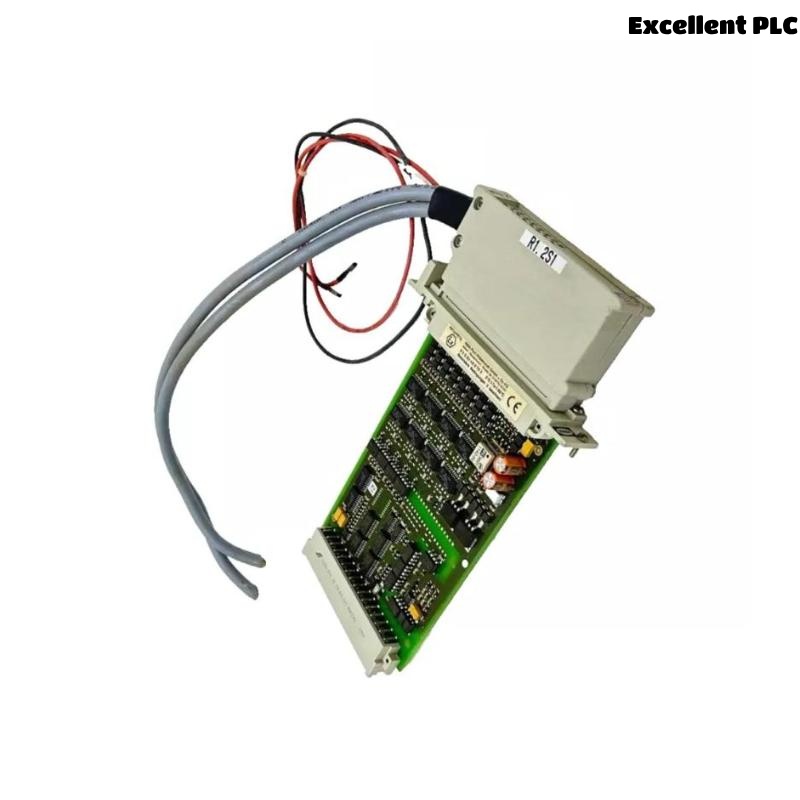

The HIMA F8651E Central Module is a high-reliability processing unit specifically engineered for safety-critical automation systems. Developed by HIMA, a global leader in functional safety solutions, the F8651E serves as the core processing element in the HIMA HIMax safety system platform. It is tailored for applications in the oil and gas, chemical, petrochemical, power generation, and transportation industries where continuous plant availability and safety compliance are paramount.

Designed with redundancy, fail-safety, and diagnostic capabilities in mind, the F8651E ensures that safety-critical operations are not compromised, even in the presence of internal hardware faults. This module is certified to comply with international safety standards including IEC 61508 SIL 3, ensuring maximum operational safety.

Product Specifications

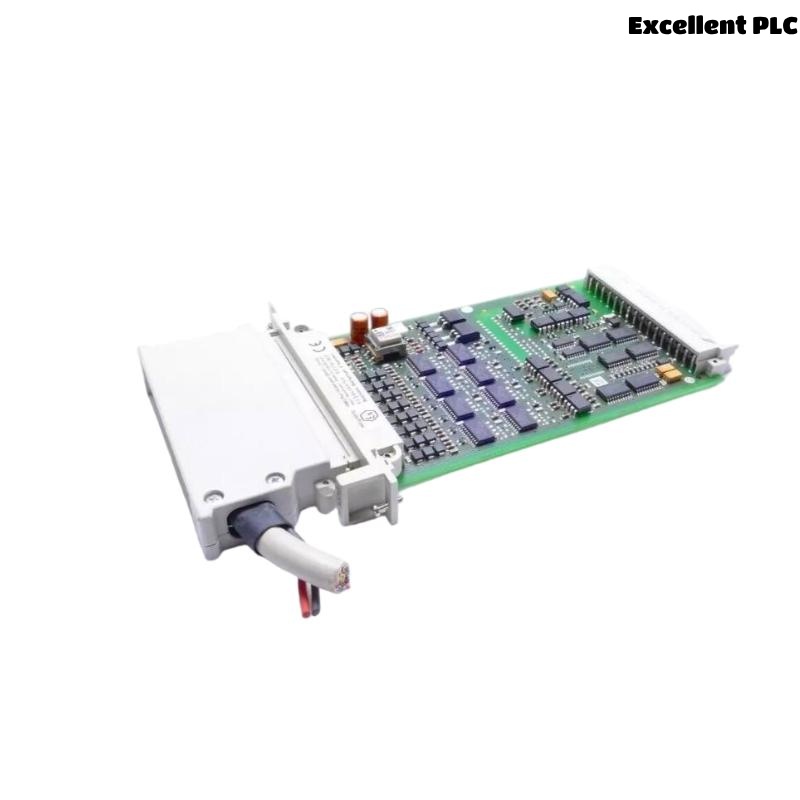

| Parameter | Description |

|---|---|

| Model Number | F8651E |

| Manufacturer | HIMA |

| Product Type | Central Processor Module |

| System Compatibility | HIMax Safety System |

| Safety Level | SIL 3 (according to IEC 61508) |

| Processor | Dual-redundant high-performance processors |

| Memory | Integrated program and data memory |

| Communication Interfaces | RS485, Ethernet, and system bus interface |

| Diagnostic Functions | Integrated diagnostics and monitoring |

| Hot-Swappable | Yes |

| Power Supply | 24 VDC (nominal) |

| Power Consumption | Approx. 8 W |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions (H x W x D) | 257 x 114 x 30 mm |

| Weight | 1.5 kg |

| Mounting Type | Plug-in module for rack system |

| Certifications | CE, SIL 3, TÜV certified |

Applications

The HIMA F8651E is widely used in various high-demand industrial sectors, where safety, availability, and reliability are non-negotiable:

-

Oil and Gas Plants – Ensures the safety of drilling, refining, and distribution processes.

-

Chemical and Petrochemical Facilities – Safeguards critical chemical processing sequences.

-

Power Generation – Applied in turbine control, boiler management, and emergency shutdowns.

-

Rail and Transportation – Used in safety controllers for signaling systems.

-

Pharmaceutical Industry – Facilitates safe production and compliance with GMP standards.

-

Water Treatment Plants – Oversees emergency response and system stability.

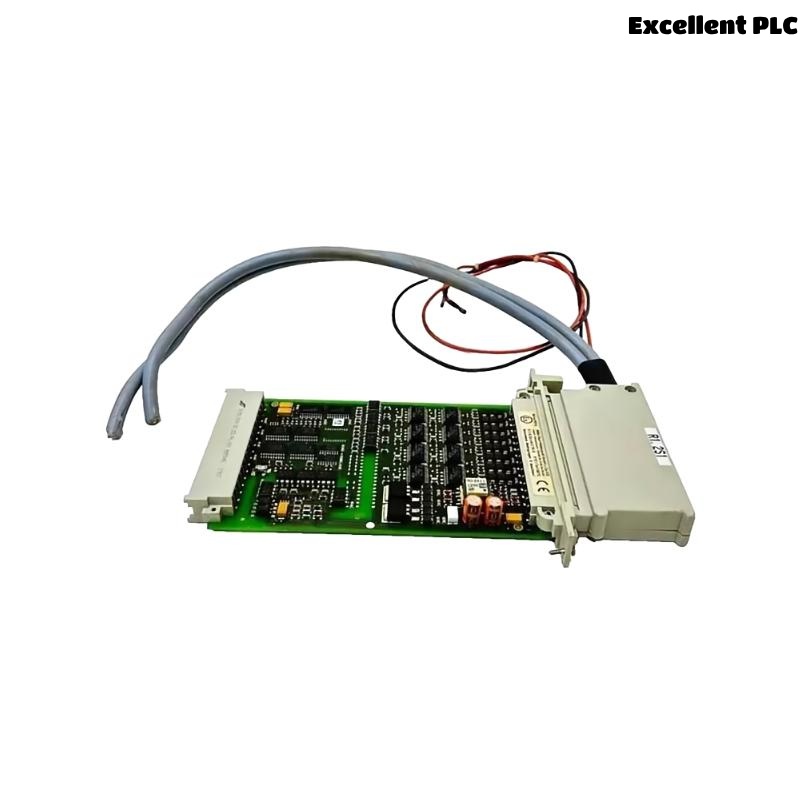

Advantages

-

Certified Safety Level: Achieves SIL 3 compliance for critical safety applications.

-

High Availability: Dual-processor architecture ensures uninterrupted operation.

-

Diagnostic Intelligence: Built-in diagnostics provide real-time fault detection and predictive maintenance.

-

Hot-Swap Capability: Enables maintenance or replacement without system downtime.

-

Modular Scalability: Compatible with HIMax systems for scalable architecture.

-

Flexible Integration: Interfaces with a wide range of I/O and communication modules.

-

Robust Design: Engineered for harsh industrial environments and continuous operation.

-

TÜV Certification: Independently tested and certified for global standards.

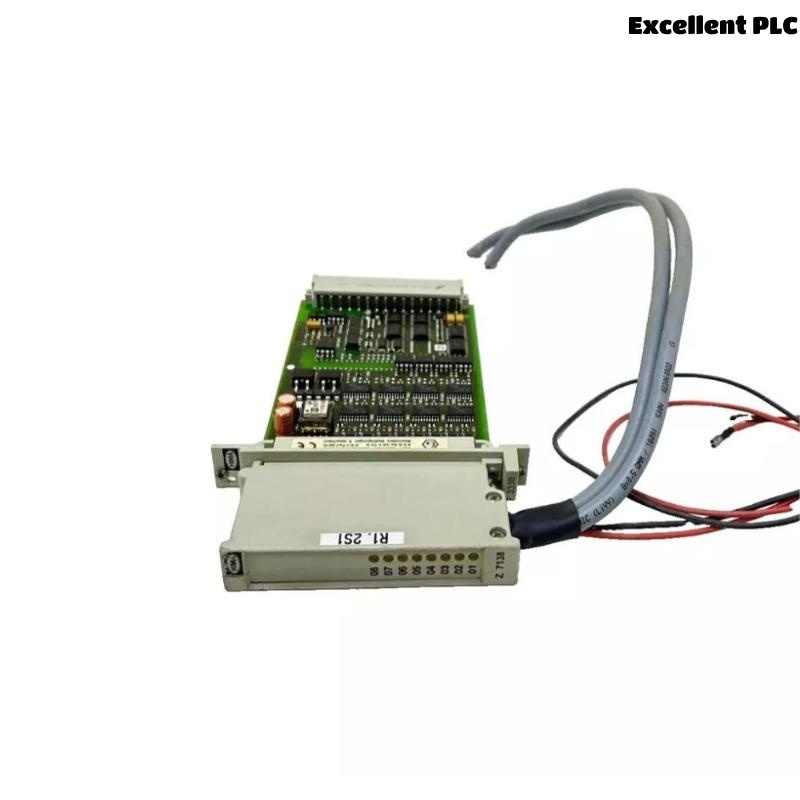

FAQ – Frequently Asked Questions

-

What system is the F8651E Central Module compatible with?

It is designed for integration with the HIMA HIMax safety system. -

Does the F8651E support SIL 3 applications?

Yes, it is certified for SIL 3 by TÜV Rheinland in accordance with IEC 61508. -

Can the module be replaced without shutting down the system?

Yes, it is hot-swappable and supports replacement during system operation. -

What communication interfaces are supported?

It supports RS485, Ethernet, and HIMA’s proprietary system bus. -

Is it possible to use the module in extreme temperatures?

The operating range is 0°C to +60°C; storage conditions range from -40°C to +85°C. -

How is system availability ensured with the F8651E?

It uses redundant processing units and continuous self-diagnostics to maintain availability. -

What industries commonly use this module?

Oil & gas, chemicals, power plants, transportation, and manufacturing. -

What is the power requirement for the F8651E?

It operates on a nominal 24 VDC power supply, consuming approximately 8 W. -

How is the module mounted?

It is a plug-in type module that fits into standard HIMax rack systems. -

Is the module compliant with European and global safety standards?

Yes, it holds CE and TÜV certifications along with SIL 3 approval.

Related Models (Same Series or Functional Group)

| Model | Description | Main Feature | System Compatibility |

|---|---|---|---|

| F8652X | Enhanced Central Module | Advanced diagnostics, higher performance | HIMax |

| F8650X | Central Processing Module | SIL 3, modular CPU redundancy | HIMax |

| F7126 | CPU Module for HIMatrix Systems | Compact safety controller | HIMatrix |

| F7553 | Communication Processor | Handles redundant communication | HIMax |

| F8653 | Central Control Unit | Dual CPU architecture | HIMax |

| F7505 | I/O Controller Module | Connects to field devices | HIMax |

Popular HIMA Models (Same Brand)

| Model | Description | Application | System |

|---|---|---|---|

| F8621A | Digital Input Module | Emergency shutdown systems | HIMax |

| F3330 | Analog Input Module | Precise analog measurements | HIMatrix |

| F6705 | Communication Module | PROFIBUS DP interface | HIMax/HIMatrix |

| F3236 | Analog Output Module | Control of actuators and valves | HIMatrix |

| F7550 | CPU Redundancy Module | Dual system CPU architecture | HIMax |

| F7128 | Safety Controller | Compact PLC for safety applications | HIMatrix |

Excellent PLC

Excellent PLC