| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

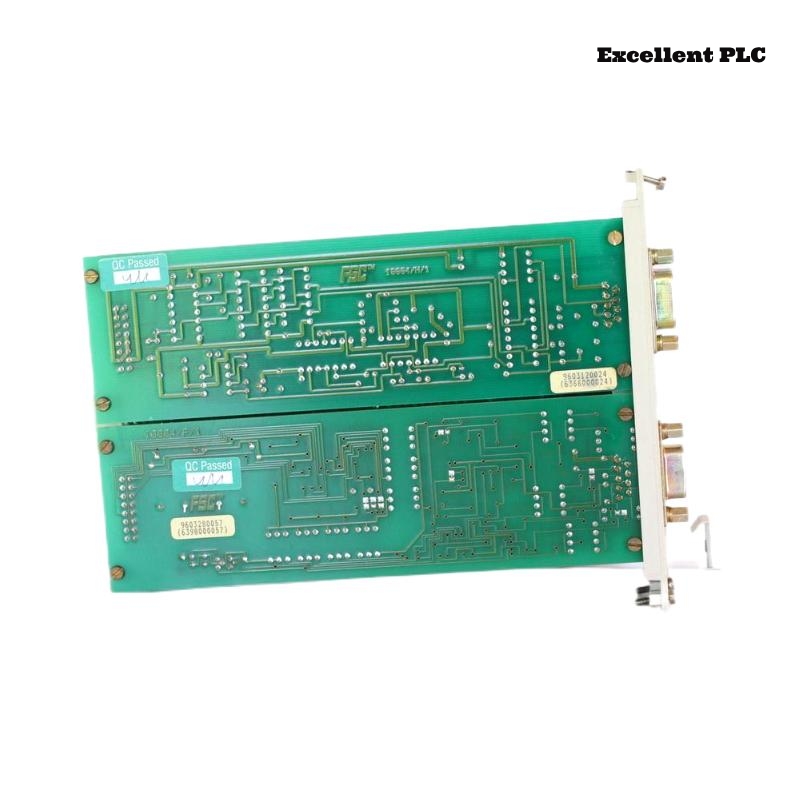

The Honeywell 10004/H/F Communication Module is an essential component in Honeywell’s industrial automation and control systems. Designed to provide seamless data transmission between various control units, this module ensures reliable communication within distributed control systems (DCS), programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) networks.

This module is engineered to support high-speed data exchange, improve system integration, and enhance real-time monitoring. It plays a crucial role in industries that require high availability, redundant communication, and secure data transmission, such as oil and gas, power generation, petrochemicals, and manufacturing.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Honeywell 10004/H/F |

| Function | Communication Module |

| Input Voltage | 24V DC |

| Power Consumption | 5W (Typical) |

| Communication Protocol | Proprietary Honeywell protocol, Modbus, Ethernet/IP |

| Baud Rate | Up to 115.2 kbps |

| Interface Ports | RS-232, RS-485, Ethernet |

| Redundancy Support | Yes |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% (non-condensing) |

| Shock Resistance | 30g, 11ms duration |

| Vibration Resistance | 2g, 10-500 Hz |

| Certifications | CE, UL, CSA |

| Mounting Type | DIN Rail / Panel Mount |

| Dimensions | 20.32 × 33.34 × 160 mm |

| Weight | 0.5 kg |

Applications

The Honeywell 10004/H/F Communication Module is widely used in:

- Industrial Automation: Facilitates real-time communication between controllers, sensors, and field devices.

- Oil & Gas Industry: Ensures secure and efficient data transfer in refineries and offshore platforms.

- Power Generation: Plays a critical role in monitoring and controlling electrical grids and turbine systems.

- Chemical & Petrochemical Plants: Enhances process automation by enabling seamless data exchange.

- SCADA & DCS Systems: Provides robust connectivity for centralized monitoring and control.

- Manufacturing: Supports high-speed communication in production lines and material handling systems.

- Water & Wastewater Treatment: Helps in real-time data acquisition and control for efficient process management.

Key Advantages

- Reliable and Secure Communication – Ensures accurate data exchange between control systems with built-in redundancy and error-checking mechanisms.

- High-Speed Data Transfer – Supports fast and real-time communication for efficient industrial automation processes.

- Multi-Protocol Compatibility – Works with Modbus, Honeywell proprietary protocols, and Ethernet/IP, allowing seamless integration into existing networks.

- Rugged Industrial Design – Built to withstand harsh environments, including extreme temperatures, vibrations, and electrical interference.

- Easy Integration – Supports both DIN rail and panel mounting, making it easy to install and configure.

- Scalability – Designed to handle expanding network demands, ensuring future-proof communication.

- Energy-Efficient Operation – Low power consumption helps in reducing overall system energy costs.

- Redundancy Support – Enhances system reliability by providing backup communication paths in case of failure.

- User-Friendly Configuration – Comes with intuitive software tools for easy setup and monitoring.

- Industry-Approved Certifications – Meets international safety and performance standards (CE, UL, CSA), ensuring compliance with global regulations.

Latest News Titles

- “Honeywell Enhances Industrial Communication with the 10004/H/F Module”

- “Honeywell’s New Communication Module Improves Data Transmission in Critical Industries”

- “Reliable Connectivity: Honeywell 10004/H/F Strengthens Industrial Automation”

- “Honeywell 10004/H/F Communication Module Expands SCADA and DCS Capabilities”

- “Ensuring Secure Data Exchange: Honeywell Introduces New Communication Technology”

FAQs

-

What is the primary function of the Honeywell 10004/H/F Communication Module?

- The module provides high-speed, secure communication between industrial controllers, sensors, and SCADA/DCS systems.

-

Which communication protocols does the module support?

- It supports Honeywell proprietary protocol, Modbus, and Ethernet/IP, making it versatile for industrial automation networks.

-

Can this module be used in hazardous environments?

- Yes, it is designed to withstand harsh industrial conditions, including high temperatures, vibrations, and electrical noise.

-

What is the maximum baud rate of the Honeywell 10004/H/F?

- The module supports a maximum baud rate of 115.2 kbps.

-

Does the module support redundant communication?

- Yes, it provides redundancy features to ensure continuous operation even in the event of a network failure.

-

How is the Honeywell 10004/H/F module mounted?

- It supports both DIN rail and panel mounting, allowing for flexible installation.

-

What is the power consumption of this module?

- The typical power consumption is 5W, making it energy-efficient.

-

Is this module compatible with older Honeywell control systems?

- Yes, it is backward compatible with many legacy Honeywell systems.

-

What safety certifications does the module have?

- It is certified with CE, UL, and CSA standards, ensuring compliance with industry regulations.

-

What industries typically use the Honeywell 10004/H/F Communication Module?

- It is widely used in oil & gas, power generation, petrochemical, manufacturing, and SCADA systems for real-time data communication.

Recommended 10 Related Models

| Model | Description |

|---|---|

| 10005/H/F | Advanced Communication Module with Extended Protocol Support |

| 10006/H/F | High-Speed Industrial Network Interface Module |

| 10100/H/F | Redundant Communication Module for SCADA/DCS |

| 10200/H/F | Wireless Communication Interface for Industrial Applications |

| 10300/H/F | Ethernet-to-Serial Bridge Module for Legacy Systems |

| 10400/H/F | Fiber Optic Communication Module for Long-Distance Data Transmission |

| 10500/H/F | Secure Data Gateway for Industrial IoT Applications |

| 10600/H/F | Modbus TCP/IP Communication Interface |

| 10700/H/F | Low-Power Communication Module for Remote Monitoring |

| 10800/H/F | Multi-Protocol Converter for PLC and DCS Systems |

10 Popular Honeywell Industrial Modules

| Model | Description |

|---|---|

| CC-PWRR01 | Power Supply Module for Industrial Controllers |

| FC-QPP-0001 | Field Controller for Process Automation |

| MC-TAMR03 | I/O Module for Analog Signal Processing |

| TC-PRR021 | Digital Input/Output Module for Industrial Automation |

| TP-APX200 | Advanced Process Controller for DCS Applications |

| TC-FXX102 | Communication Interface for SCADA Networks |

| CC-TDIL01 | High-Density Digital Input Module |

| CC-TDOB01 | Digital Output Module for PLCs and DCS Systems |

| MC-PDIX02 | Profibus Communication Interface for Industrial Networks |

| TK-PPD011 | Programmable Controller for Critical Industrial Processes |

Excellent PLC

Excellent PLC