| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

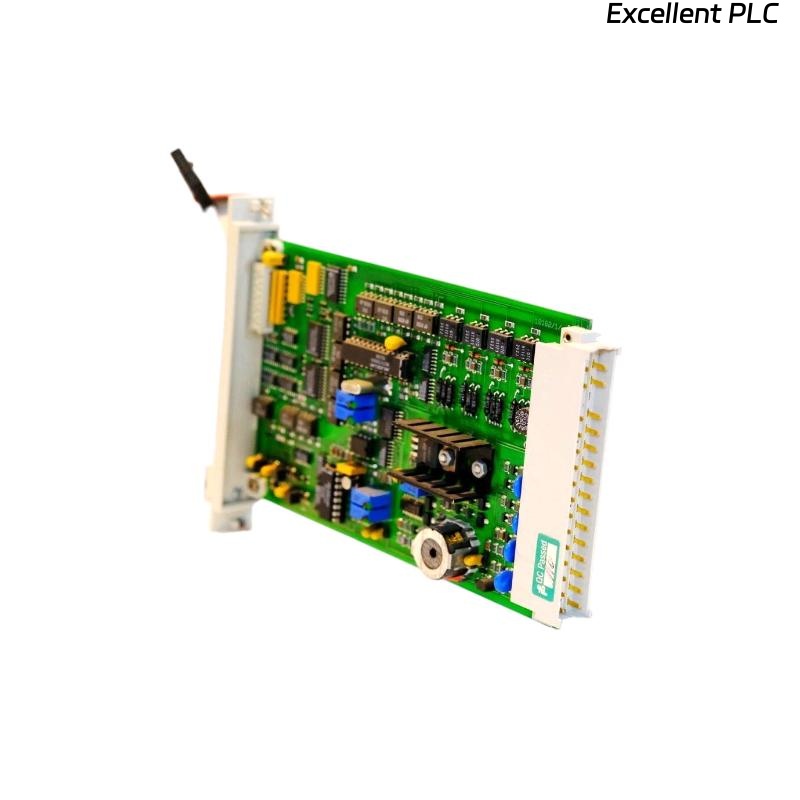

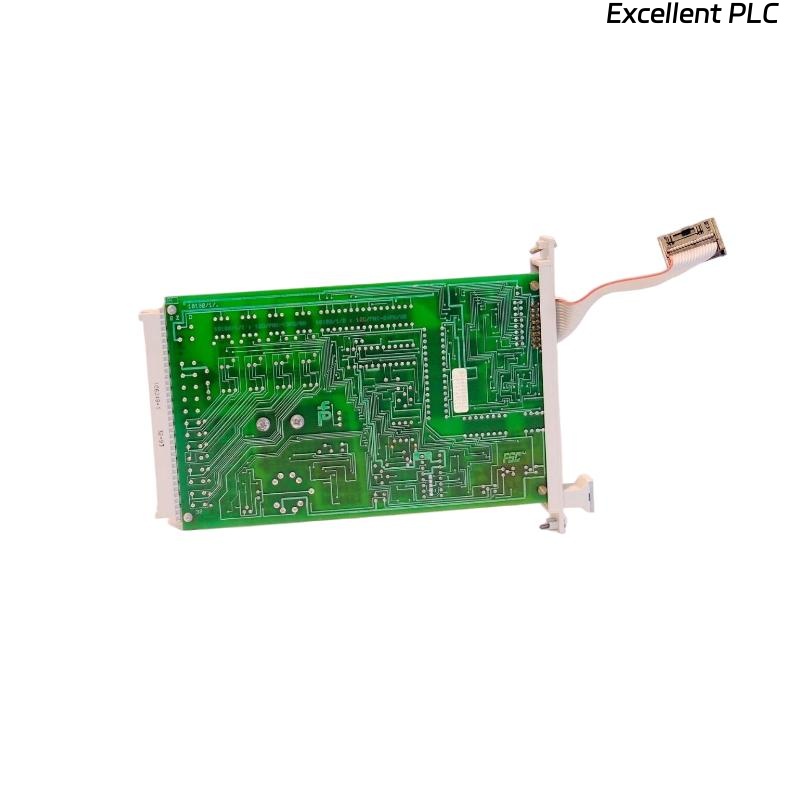

The Honeywell 10102/1/2 Fault-Tolerant Analog Input Module is designed to provide high-performance, reliable analog input capabilities for industrial control systems. This module is essential in applications where safety, precision, and fault tolerance are paramount. The 10102/1/2 is part of Honeywell’s fault-tolerant series, ensuring continuous operation even under failure conditions, making it ideal for use in critical industries like process control, manufacturing, and safety monitoring.

This module supports a wide range of input signals, including voltage and current, and is equipped with features to ensure that even if one input channel fails, the other channels continue to operate without interruption. With a compact size and robust build, the 10102/1/2 is easy to install and provides long-term durability, reducing the need for frequent maintenance and minimizing the risk of system downtime.

The Honeywell 10102/1/2 module is designed for environments where the failure of an input could lead to catastrophic outcomes. Its fault-tolerant design ensures that the system remains operational, thus safeguarding processes, machinery, and, most importantly, people. This makes it a key component for applications that demand continuous, accurate, and reliable data acquisition.

Product Specifications

| Specification | Details |

|---|---|

| Dimensions (L x W x H) | 186 x 112 x 30 mm |

| Weight | 0.181 kg |

| Input Type | Voltage and Current (Analog) |

| Channels | 8 Analog Input Channels |

| Resolution | 16-bit (for Analog Inputs) |

| Input Voltage Range | 0-10V or 4-20mA (Configurable) |

| Isolation | 500V AC isolation between inputs |

| Input Impedance | 1 MΩ (for Voltage Inputs) |

| Power Supply | 24V DC ± 10% |

| Operating Temperature | -40°C to +70°C |

| Mounting | DIN Rail Mounted |

| Response Time | < 10 ms for Analog Inputs |

| Environmental Protection | IP20 (or IP65 with optional cover) |

Product Applications

The Honeywell 10102/1/2 Fault-Tolerant Analog Input Module is versatile and suitable for a wide range of applications across various industries. Below are some of the key applications:

-

Process Control Systems

The module plays a critical role in process control by gathering data from sensors that measure temperature, pressure, flow, and level. In industries such as chemicals, petrochemicals, and pharmaceuticals, the accuracy and fault tolerance of the 10102/1/2 are essential for ensuring that critical parameters are monitored without fail. -

Manufacturing Automation

In automated manufacturing processes, this module monitors vital production parameters. The fault-tolerant design ensures that input data continues to be received and processed even if one channel encounters an issue, reducing the risk of production downtime and increasing system reliability. -

Safety Monitoring Systems

The 10102/1/2 is used in safety-critical applications, where real-time data from sensors is required to trigger alarms or shut down systems in case of unsafe conditions. It provides continuous monitoring and helps ensure that safety systems function properly in the event of a fault. -

Energy and Utilities

In power generation and distribution systems, the module is used to monitor electrical parameters such as voltage and current. Its fault-tolerant design ensures continuous data acquisition, even in the event of failures, ensuring that the system remains operational and safe. -

HVAC Systems

The 10102/1/2 module is also used in HVAC systems to monitor critical environmental variables such as temperature and humidity. In these systems, fault tolerance is vital to ensure optimal operation of heating, ventilation, and air conditioning. -

Remote Monitoring and Diagnostics

The module can be employed in remote monitoring systems, ensuring that data is accurately collected and transmitted back to a central monitoring station. It enables operators to monitor the health of systems and perform diagnostics even from a distance.

Product Advantages

-

Fault-Tolerant Design

The 10102/1/2 is specifically designed for fault tolerance. If one input channel fails, the remaining channels continue to function. This design ensures that data acquisition continues without interruption, providing high system reliability even in critical applications. -

High Accuracy and Resolution

With 16-bit resolution, the module provides highly accurate data for precise control and monitoring. This accuracy is especially important in process control and safety applications where small variations can lead to significant operational issues. -

Wide Input Range

The 10102/1/2 module supports both voltage (0-10V) and current (4-20mA) inputs, allowing it to be used with a variety of sensor types and applications. This wide input range increases its flexibility and makes it suitable for a broad array of industrial processes. -

Robust and Compact Design

With dimensions of 186 x 112 x 30 mm and a weight of 0.181 kg, the module has a compact form factor that allows for easy integration into control panels or enclosures. Its robust design ensures it can withstand harsh industrial conditions. -

High Electrical Isolation

The module offers 500V AC isolation between the inputs, providing protection against electrical noise and surges. This helps maintain the integrity of the data and reduces the likelihood of faults caused by electrical interference. -

Scalable and Flexible

The module’s design allows it to be easily scaled and integrated into large control systems. With 8 analog input channels and the ability to handle multiple signal types, it can be used in complex systems that require reliable, fault-tolerant input monitoring. -

Wide Temperature Range

The module operates in a wide temperature range of -40°C to +70°C, making it suitable for use in both extreme indoor and outdoor environments. -

Easy Installation

The 10102/1/2 is designed to be easily mounted on a DIN rail, simplifying the installation process. This allows for quick setup and reduces installation time, which is beneficial in fast-paced industrial environments.

FAQ

Q1: What types of inputs are supported by the 10102/1/2 module?

A1: The 10102/1/2 module supports both voltage (0-10V) and current (4-20mA) inputs.

Q2: How many input channels does the module have?

A2: The module has 8 analog input channels.

Q3: What is the resolution of the analog inputs?

A3: The analog inputs have 16-bit resolution, ensuring high precision.

Q4: What is the power supply requirement for the 10102/1/2 module?

A4: The module operates with a 24V DC power supply, with a tolerance of ±10%.

Q5: What is the operating temperature range of the 10102/1/2?

A5: The module operates in temperatures ranging from -40°C to +70°C.

Q6: Can the 10102/1/2 module be used in hazardous environments?

A6: The 10102/1/2 is designed for industrial applications, but it is not certified for use in explosive or hazardous environments unless specified for such use.

Q7: How is the module mounted?

A7: The module is DIN rail mountable, which simplifies installation in control panels.

Q8: What is the electrical isolation of the 10102/1/2 module?

A8: The module provides 500V AC isolation between inputs.

Q9: Is the 10102/1/2 suitable for use in large systems?

A9: Yes, the module is scalable and can be easily integrated into large systems that require fault-tolerant analog input monitoring.

Q10: What is the weight of the 10102/1/2 module?

A10: The module weighs 0.181 kg, making it lightweight and easy to handle during installation.

Recommended Models

| Model | Description |

|---|---|

| 10103/1/2 | Fault-tolerant module with extended analog channels. |

| 10104/1/2 | Enhanced analog input module with higher resolution. |

| 10105/1/2 | Compact fault-tolerant analog input module for smaller applications. |

| 10106/1/2 | Advanced fault-tolerant module with additional isolation. |

| 10107/1/2 | High-density analog input module with integrated diagnostics. |

| 10108/1/2 | Digital and analog input module with fault tolerance for large systems. |

Popular Models

| Model Number | Description |

|---|---|

| 10206/2/1 | High-precision sensor for industrial machinery monitoring |

| 10102/1/1 | General-purpose vibration sensor for equipment monitoring |

| 10206/2/2 | Advanced vibration sensor with enhanced sensitivity |

| 10102/1/2 | Vibration sensor designed for rotating machinery |

| 10206/2/3 | Vibration sensor with real-time diagnostic capabilities |

| 10102/1/3 | Heavy-duty vibration sensor for critical machinery |

Excellent PLC

Excellent PLC