| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

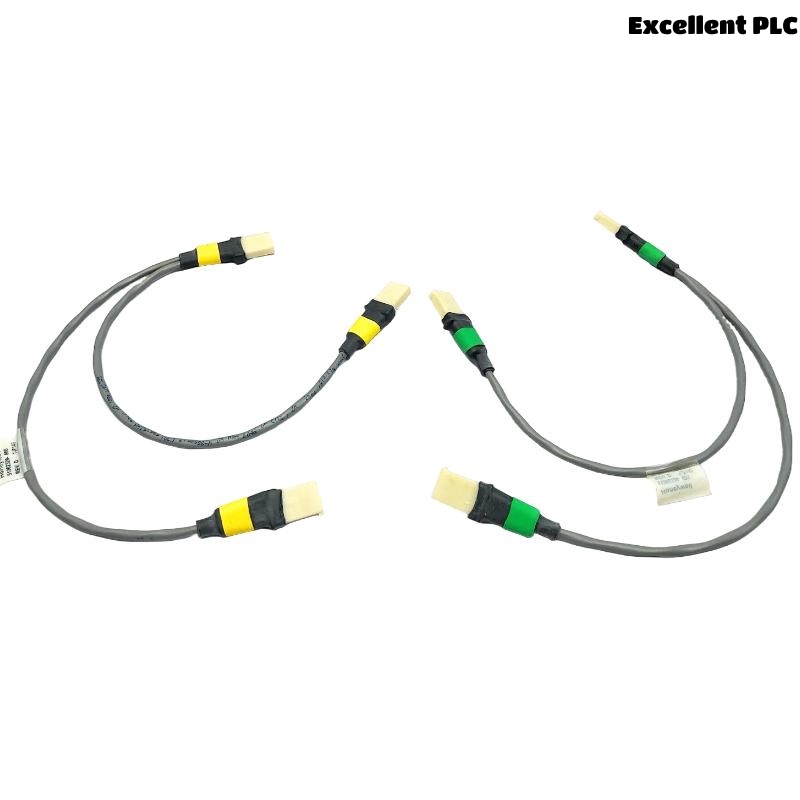

The Honeywell 51202329-600 Violet Drop Cable is a robust industrial-grade communication cable designed specifically for Honeywell’s Distributed Control System (DCS) environments, including the TDC 3000 system. This cable plays a critical role in ensuring reliable signal transmission between controllers, I/O modules, and network interfaces in complex industrial automation setups.

With its distinctive grey-colored jacket, the 51202329-600 is easy to identify and trace within dense cabling infrastructures. It is engineered with durable materials and dual-layer shielding to offer high resistance against electromagnetic interference (EMI), mechanical wear, and harsh environmental conditions. Its high signal integrity, mechanical strength, and temperature resistance make it an ideal solution for high-performance industrial connectivity.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 51202329-600 |

| Product Type | Violet Drop Cable |

| Manufacturer | Honeywell |

| Conductor Type | Twisted Pair, Tinned Copper |

| Conductor Size | 22 AWG |

| Shielding | Foil and Braid Shielding |

| Jacket Material | Industrial-grade PVC |

| Insulation Material | Flame-retardant PVC |

| Rated Voltage | 300V |

| Impedance | 150 Ohms ±10% |

| Temperature Range | -40°C to +85°C |

| Flame Retardancy | UL Listed Flame-retardant |

| Certifications | UL, CSA, CE |

| Outer Diameter | 7.5 mm |

| Package Weight | 3 kg |

| Drop Cable | 3 Drop |

| Application Compatibility | Honeywell TDC 3000, Process Control Networks |

Applications

The Honeywell 51202329-600 cable is widely deployed across multiple industrial sectors for reliable process communication. Key applications include:

-

Distributed Control Systems (DCS): Optimized for Honeywell TDC 3000, it supports interconnections between control modules and I/O systems.

-

Process Automation: Used in oil refineries, petrochemical plants, and chemical processing facilities for signal transmission.

-

Factory Automation: Ensures accurate communication between programmable logic controllers (PLCs) and peripheral devices.

-

Energy and Power Generation: Suitable for power plants requiring high EMI immunity and long-distance signal integrity.

-

Industrial Ethernet and Control Networks: Can support legacy and hybrid Ethernet deployments in automation systems.

Product Advantages

-

Enhanced EMI Shielding: Features both foil and braid shielding for superior protection against electrical noise.

-

Industrial-grade Durability: Resistant to abrasion, oil, chemical exposure, and extreme temperatures.

-

Color-coded Jacket: Grey outer layer helps in quick identification and error-free maintenance.

-

Flexible Installation: Compact design allows easy routing through cable trays, ducts, or narrow pathways.

-

System Compatibility: Seamlessly integrates with Honeywell control architecture and other compliant systems.

-

High Signal Integrity: Low capacitance and controlled impedance maintain clear, reliable data transmission over long distances.

Frequently Asked Questions (FAQ)

1. What systems is the 51202329-600 cable designed for?

It is specifically designed for Honeywell’s TDC 3000 Distributed Control System, supporting reliable data transmission between controllers and I/O modules.

2. Why does this cable have a grey outer jacket?

The grey color provides quick visual identification, helping technicians trace and manage cables efficiently during installation and maintenance.

3. What type of shielding is used in this cable?

It features both foil and braided shielding, offering dual-layer protection to minimize signal disruption from electromagnetic interference.

4. Can this cable be used in high-vibration environments?

Yes, the cable is built for industrial use and withstands mechanical stress, including vibration in plant and field installations.

5. Is it suitable for chemical or oil-exposed environments?

Yes, the outer jacket is made of industrial-grade PVC, which resists exposure to oils, solvents, and many industrial chemicals.

6. What temperature range can the cable withstand?

The cable operates reliably in temperatures ranging from -40°C to +85°C, making it suitable for both hot and cold industrial zones.

7. Is this cable rated for flame resistance?

Yes, it meets UL flame-retardant standards and is designed to maintain performance in environments where fire safety is critical.

8. How is this cable typically installed?

It can be routed through trays, conduits, or control cabinets, and its flexible design allows for easy handling even in confined spaces.

9. What conductor material is used?

The conductors are made of tinned copper, providing strong electrical conductivity and resistance to corrosion.

10. Does this cable support long-distance signal transmission?

Yes, the cable’s impedance control and low capacitance allow for stable, interference-free communication over extended distances.

Related or Compatible Models (Same Series/Function)

| Model | Description |

|---|---|

| 51202329-412 | Violet Drop Cable, Standard Shielding for TDC 3000 |

| 51202329-113 | Violet Drop Cable, High-Temp Variant |

| 51201420-100 | Network Cable for Enhanced EMI Environments |

| 51400990-100 | ControlNet Cable for Honeywell Process Systems |

| 51309586-100 | Ethernet Drop Cable for Redundant Network Links |

| 51309150-175 | Flexible Remote I/O Drop Cable, Flame-Retardant Design |

Popular Honeywell Models (Same Brand – High Demand)

| Model | Description |

|---|---|

| CC-PDIL01 | Pulse Input Module for Process Control |

| FC-TSDI-1624 | 16-Channel Digital Input Module for Safety Manager |

| TC-CCR013 | Control Processor for Experion PKS C300 Systems |

| CC-TCNT01 | Counter Input Module for High-Speed Applications |

| MU-TD0D12 | Digital Output Module for TDC 3000 |

| 51401437-100 | Fiber Optic Ethernet Cable for Fault-Tolerant Networks |

Excellent PLC

Excellent PLC