| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

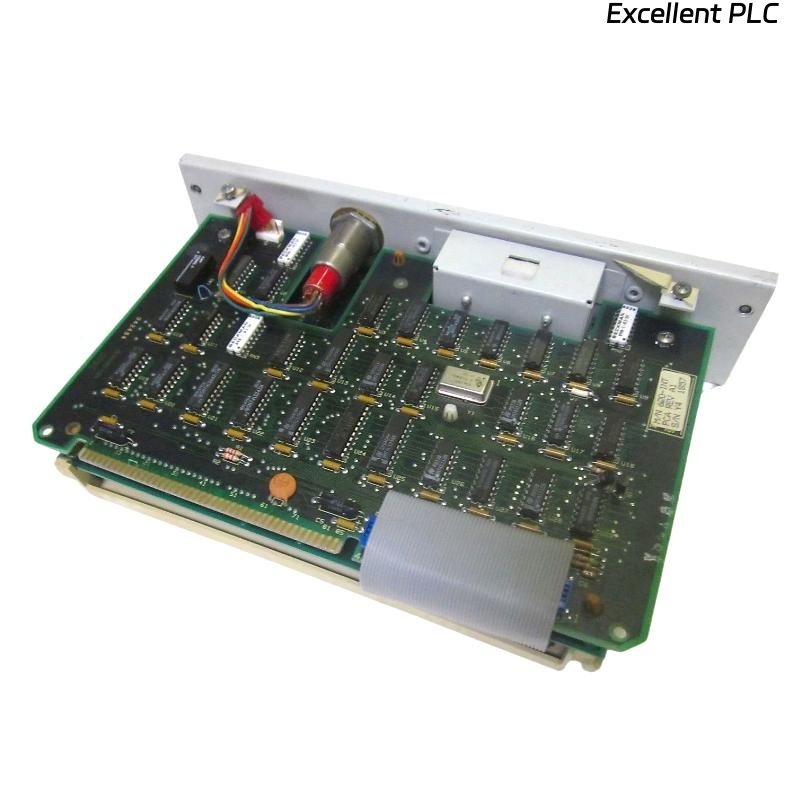

The Honeywell 620-1531 Processor Module is the central computing unit for Honeywell’s IPC-620 series control systems. Serving as the system’s brain, it executes control algorithms, manages communications with I/O modules, and processes data from field devices in real-time.

Designed for industrial automation applications, this processor module ensures reliable and deterministic control, even under high-load conditions. It supports multitasking of various process control operations, data logging, diagnostics, and interfacing with communication modules. The 620-1531 is optimized for seamless integration with Honeywell’s modular rack architecture, providing engineers with flexible system configuration and scalable control solutions.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Honeywell |

| Model | 620-1531 |

| Product Type | Processor Module |

| Function | Central control and processing for IPC-620 system |

| CPU Type | Industrial-grade microprocessor |

| Memory | On-board RAM and firmware storage for control programs |

| I/O Interface | Compatible with IPC-620 I/O modules and communication modules |

| Communication Ports | Internal bus for I/O, serial ports for ASCII and network communication |

| Operating Voltage | Supplied via system backplane |

| Operating Temperature Range | 0°C to 60°C |

| Storage Temperature Range | -40°C to 85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Fault Detection | Supports system diagnostics and fault reporting |

| Mounting | Rack-mounted in IPC-620 chassis |

| Dimensions (H × W × D) | 230 × 40 × 160 mm |

| Weight | 0.99 kg |

Product Applications

The 620-1531 Processor Module is used in:

-

Process Control Systems – Coordinating I/O, control logic, and system monitoring for chemical, petrochemical, and power plants.

-

Batch Manufacturing – Running sequential control programs for precise production processes.

-

Utilities and Infrastructure – Managing water treatment, waste management, and energy distribution processes.

-

Oil & Gas – Supervising pipeline and wellhead control systems.

-

Data Acquisition and Logging – Collecting and processing data from distributed sensors for analysis and reporting.

-

SCADA Integration – Acting as the core computing engine for supervisory control and automation systems.

Product Advantages

-

High Reliability – Industrial-grade processor ensures continuous operation in critical environments.

-

Real-Time Processing – Fast execution of control programs for deterministic responses.

-

Flexible Communication – Supports multiple interfaces including serial ASCII and network connections.

-

Scalable Architecture – Integrates with various I/O modules, communication modules, and simulation modules.

-

Built-in Diagnostics – Monitors system performance and reports faults for preventive maintenance.

-

Easy Integration – Compatible with Honeywell IPC-620 racks and modules, simplifying system expansion.

FAQ

-

What is the primary function of the 620-1531 module?

It serves as the central processor for the IPC-620 control system, executing control logic and managing I/O. -

What type of CPU does it use?

An industrial-grade microprocessor optimized for real-time control. -

How does the processor communicate with I/O modules?

Through the internal bus of the IPC-620 system rack. -

Does the module support serial communication?

Yes, it supports ASCII serial communication via dedicated ports. -

Can it handle multiple control tasks simultaneously?

Yes, it is capable of multitasking for various process control and monitoring operations. -

Is the module hot-swappable?

No, the system should be powered down before installation or removal. -

Does the processor include fault detection?

Yes, it provides diagnostics and fault reporting for system monitoring. -

What are the environmental operating limits?

0°C to 60°C operating temperature and 5% to 95% relative humidity. -

How much memory is available for control programs?

Memory includes on-board RAM and firmware storage sufficient for typical IPC-620 applications. -

Is it compatible with other Honeywell IPC-620 modules?

Yes, fully compatible with I/O, communication, and simulator modules in the IPC-620 series.

Recommended Related Models – Same Series or Similar

| Model | Description | Key Features |

|---|---|---|

| 620-1530 | Processor Module | Standard CPU for IPC-620 systems |

| 620-1532 | Redundant Processor Module | Dual CPU configuration for high availability |

| 620-0057 | I/O Control Module | Manages distributed I/O communication |

| 621-0012 | ASCII Communication Module | Serial ASCII data interface |

| 621-0009 | Simulator Input Module | Input simulation for testing and commissioning |

| 621-0003 | Analog Output Module | Precision analog control outputs |

Popular Honeywell Models – Same Brand

| Model | Description | Key Features |

|---|---|---|

| 620-1530 | Processor Module | Standard IPC-620 CPU |

| 620-0057 | I/O Control Module | Distributed I/O management |

| 621-0012 | ASCII Communication Module | Serial interface for external devices |

| 621-0003 | Analog Output Module | Precision analog outputs |

| 621-0009 | Simulator Input Module | Signal simulation for testing |

| 621-0004 | Digital Output Module | Relay and transistor-based outputs |

Excellent PLC

Excellent PLC