| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

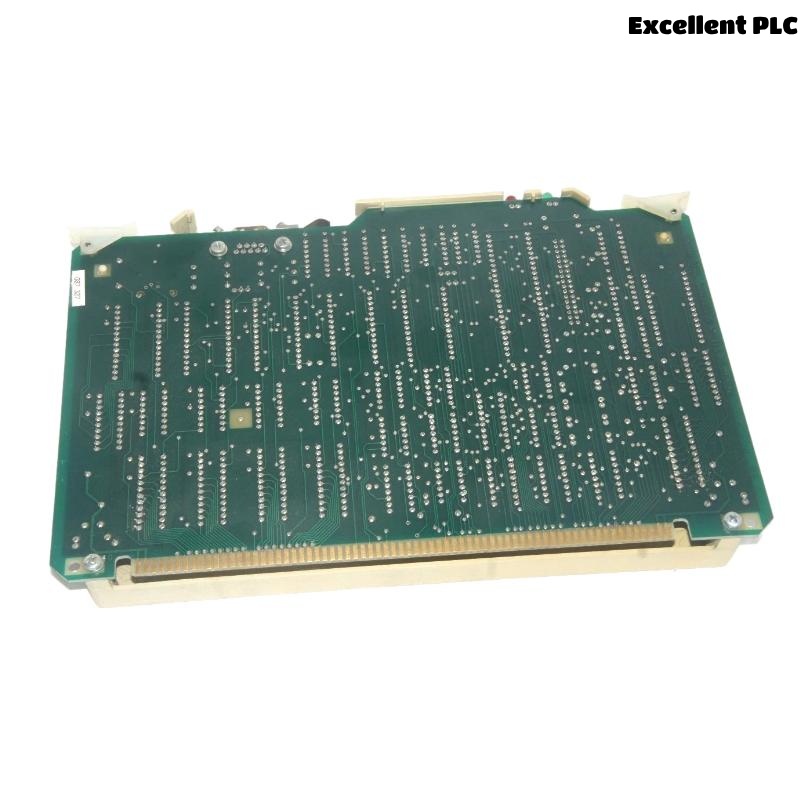

The Honeywell 620-25/35 Processor Module is a central processing unit used in Honeywell’s TDC 2000 and TDC 3000 Distributed Control Systems (DCS). As a high-performance controller, it plays a vital role in executing control strategies, managing I/O communications, and maintaining real-time process operations. Designed with a robust architecture and fault-tolerant capabilities, the 620-25/35 is built to handle demanding industrial environments with maximum reliability and long-term operational stability.

The module is based on a proprietary control platform and is capable of hosting complex logic sequences, PID loops, batch control routines, and data acquisition tasks. It ensures seamless integration into Honeywell’s legacy control infrastructures while supporting high-speed communication with I/O modules and operator stations.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | Honeywell 620-25/35 |

| Product Type | Processor Module / CPU |

| System Compatibility | TDC 2000, TDC 3000 |

| Processor Architecture | Proprietary Honeywell processor |

| Main Functions | Control execution, I/O communication, diagnostics |

| Memory Capacity | Up to 512 KB RAM (system-dependent) |

| Program Storage | EPROM / Flash-based, system configurable |

| Input Voltage | Supplied through system backplane (typically 5 VDC) |

| Communication Interface | Honeywell I/O Bus, redundant communication path |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5%–95% non-condensing |

| Mounting Method | Rack-mounted |

| Redundancy Support | Yes, for high availability systems |

| Hot Swap Capability | No (requires system stop for replacement) |

| Dimensions (W x H x D) | 165 x 280 x 51 mm |

| Weight | 0.522 kg |

| Certifications | UL, CE, CSA, ATEX (system-dependent) |

Product Applications

The Honeywell 620-25/35 Processor Module is primarily used in the following industrial applications:

-

Petrochemical Plants: For centralized control of critical process units such as distillation, cracking, and blending systems.

-

Power Generation: Manages boiler control, turbine automation, and balance-of-plant systems.

-

Oil & Gas Facilities: Supervises drilling platforms, gas compression stations, and pipeline automation.

-

Water Treatment Plants: Controls chemical dosing, filtration cycles, and remote terminal units (RTUs).

-

Pharmaceutical Manufacturing: Executes complex batch recipes and maintains strict regulatory compliance (e.g., FDA 21 CFR Part 11).

-

Food & Beverage Processing: Provides deterministic control for packaging lines, pasteurization, and storage systems.

Product Advantages

-

Robust Performance: Delivers stable, real-time control under high process loads.

-

System Compatibility: Fully compatible with legacy TDC 2000/3000 systems, extending the life of installed infrastructure.

-

Secure Memory Architecture: Program logic is retained through power cycles using EPROM or Flash memory.

-

Redundant Operation: Supports processor redundancy for uninterrupted control during hardware failure.

-

Seamless Communication: Interfaces with operator stations, I/O modules, and peer controllers over a reliable I/O bus.

-

Long-Term Support: Supported under Honeywell’s Lifecycle Support policy, ensuring availability of spares and updates.

-

Diagnostic Features: Offers fault reporting and status indicators to aid in troubleshooting and performance monitoring.

-

Proven Field Experience: Successfully deployed in thousands of process facilities globally.

-

Compact Footprint: High processing power in a small, rack-mountable form factor.

-

Scalability: Easily adaptable to large-scale or complex distributed control architectures.

Frequently Asked Questions (FAQ)

1. What is the difference between the 620-25 and 620-35 variants?

The 620-25 typically supports standard applications with moderate control loads, while the 620-35 offers enhanced performance and is designed for more complex control strategies or higher I/O volumes.

2. Can the 620-25/35 operate in a redundant CPU configuration?

Yes. The processor supports full redundancy, allowing a backup unit to take over automatically in the event of primary failure, ensuring uninterrupted process control.

3. Is the processor module programmable via standard software tools?

Yes. It is configured and programmed using Honeywell’s legacy engineering tools such as EPD (Executive Programming Device) or other control configuration tools tailored for TDC systems.

4. How does the processor communicate with other system components?

It uses Honeywell’s proprietary I/O bus to communicate with field I/O modules and control network interfaces, ensuring low-latency and high-integrity data transmission.

5. Does the 620-25/35 support flash updates or firmware upgrades?

Firmware is typically stored in non-volatile memory (EPROM or Flash). While updates are possible, they often require system engineering support and strict configuration management.

6. What are the implications of replacing this processor module in a live system?

The 620-25/35 is not hot-swappable. Replacing it requires halting the processor rack and following system shutdown procedures to avoid data corruption or system faults.

7. How is memory protected against power loss?

Non-volatile memory options and system backup procedures ensure that configuration and program data are retained during power outages or unexpected shutdowns.

8. What type of diagnostics are available for troubleshooting?

The module includes onboard LED indicators and internal checks for memory errors, processor faults, and communication integrity. Fault status can also be accessed via the operator interface.

9. Are there industry certifications for hazardous environments?

Yes. Depending on the system configuration, the 620-25/35 may be certified for use in ATEX Zone 2 and other industrial hazardous zones.

10. Is this processor suitable for cybersecurity-sensitive environments?

While originally developed before modern cybersecurity standards, the module can be used in secure network zones with appropriate firewalls, physical access restrictions, and Honeywell’s updated security recommendations.

Related Models in the Same Series

| Model Number | Description | Function | Compatibility |

|---|---|---|---|

| 620-0081 | Digital Output Module | Outputs digital control signals | TDC 2000 / TDC 3000 |

| 620-0085 | Analog Input Module | Acquires process variables | TDC 2000 / TDC 3000 |

| 620-1036 | Multiplexer Module | Manages multiple I/O signals | TDC 2000 / TDC 3000 |

| 620-0056 | I/O Link Interface | Connects processor to I/O racks | TDC 2000 / TDC 3000 |

| 620-0080 | Digital Input Module | Receives binary input signals | TDC 2000 / TDC 3000 |

| 620-2100 | Power Supply Module | Supplies voltage to processor | TDC 2000 / TDC 3000 |

Popular Honeywell Models

| Model Number | Description | System | Primary Function |

|---|---|---|---|

| CC-PCNT01 | Pulse Input Module (Series C) | Experion PKS | Pulse signal processing |

| CC-TAIX01 | Analog Input Module | Experion PKS | Field signal acquisition |

| CC-TDOR01 | Digital Output Module | Experion PKS | Control signal output |

| FC-PDB-0824P | Power Distribution Module | Safety Manager | Power management |

| TC-PRR021 | Redundant Processor (C300) | Experion PKS | Advanced control execution |

| MU-TD0D12 | Digital Output Module | TDC 3000 | 24-channel digital output |

Excellent PLC

Excellent PLC