| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

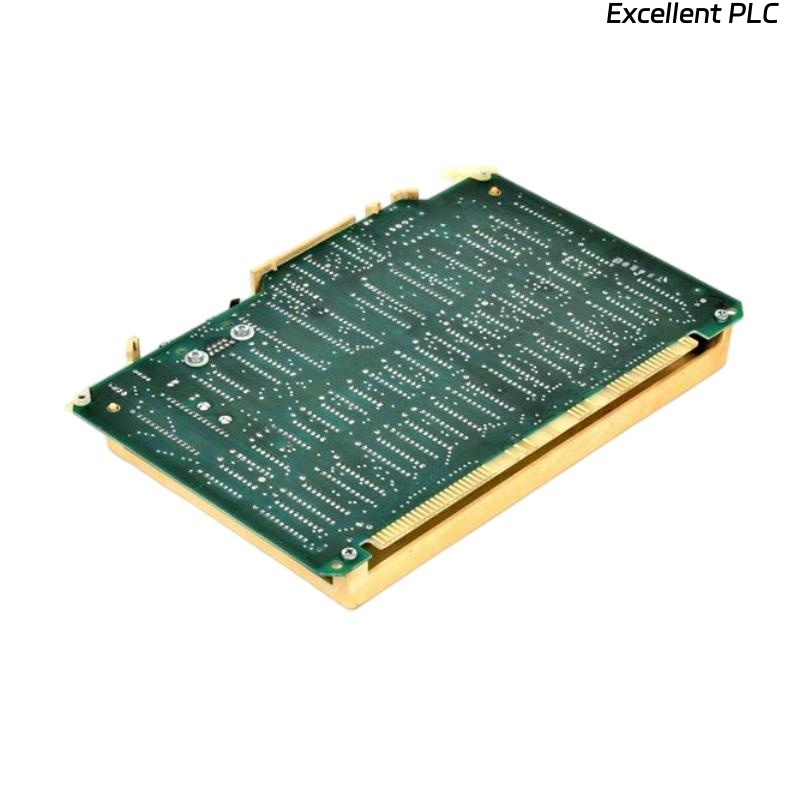

The Honeywell 620-3030 Processor Module is a high-performance, industrial-grade processing unit designed to facilitate seamless control, processing, and data management within automated systems. It serves as the central hub for complex automation systems, providing real-time data processing, monitoring, and communication across multiple connected devices and systems. Optimized for high availability and reliability, the 620-3030 Processor Module is ideal for mission-critical applications where system uptime and precision are paramount. It can handle large-scale data processing tasks with ease, ensuring smooth and efficient system operations.

The module is designed for use in a variety of industrial sectors, including energy, manufacturing, and automation, where robust performance, secure data handling, and fault tolerance are required. It integrates well into Honeywell’s broader automation solutions and ensures minimal downtime during system upgrades or expansions.

Product Parameters

Below are the detailed specifications of the Honeywell 620-3030 Processor Module:

| Parameter | Value |

|---|---|

| Model | 620-3030 |

| Dimensions (L x W x H) | 260 x 140 x 30 mm |

| Weight | 0.367 kg |

| Power Supply | 24V DC |

| Communication Protocol | Ethernet, Modbus |

| Operating Temperature | -10°C to 60°C |

| Mounting Type | Panel Mount, DIN Rail |

Product Applications

The Honeywell 620-3030 Processor Module can be deployed in a wide range of industrial applications to handle diverse data processing and control tasks:

-

Industrial Automation: The module acts as the processing core for managing complex control loops, enabling process automation in manufacturing plants.

-

Energy Management: It monitors real-time data from energy systems, providing insights for optimization and energy consumption reduction.

-

Manufacturing Control: It integrates with PLCs (Programmable Logic Controllers) to control machinery, conveyors, and other manufacturing equipment, ensuring continuous operation.

-

Process Automation Systems: Used to automate repetitive tasks, ensuring higher throughput and reduced risk of errors.

-

Building Management Systems: Ensures integrated communication between various building systems such as HVAC, lighting, and security.

Product Advantages

The Honeywell 620-3030 Processor Module offers several key benefits that make it a standout solution for industrial automation:

-

High Processing Power: Designed for demanding applications that require high computational capabilities, ensuring seamless system operations.

-

Versatile Communication: Supports multiple communication protocols including Ethernet and Modbus, providing flexibility in integration with existing systems.

-

Reliability and Robustness: Built to endure harsh industrial environments with a wide operating temperature range and fault-tolerant features.

-

Easy Integration: The processor module integrates smoothly with Honeywell’s suite of automation solutions, reducing system integration time and improving operational efficiency.

-

Scalability: Capable of handling a large number of input/output points, making it suitable for systems of all sizes.

-

Compact Design: Despite its powerful features, the module has a compact form factor, allowing for efficient use of space within control panels.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Honeywell 620-3030 Processor Module?

-

It serves as a high-performance processing unit for managing control, communication, and data handling tasks in industrial automation systems.

-

-

What communication protocols does the module support?

-

The 620-3030 supports Ethernet and Modbus communication protocols, offering seamless integration with other industrial devices and systems.

-

-

What is the operating temperature range for this processor module?

-

The module operates within a temperature range of -10°C to 60°C, making it suitable for use in a variety of industrial environments.

-

-

Is the Honeywell 620-3030 compatible with Honeywell’s other automation products?

-

Yes, the 620-3030 is designed to integrate seamlessly with other Honeywell automation solutions, enhancing system performance and reliability.

-

-

How is the Honeywell 620-3030 mounted?

-

The processor module can be mounted either on a panel or a DIN rail, offering flexible installation options.

-

-

What is the weight of the Honeywell 620-3030 Processor Module?

-

The weight is 0.367 kg, making it lightweight yet robust for industrial environments.

-

-

What types of applications is the Honeywell 620-3030 used for?

-

It is used in industrial automation, energy management, manufacturing control, process automation systems, and building management systems.

-

-

Does this module have fault tolerance features?

-

Yes, the module is designed to be fault-tolerant, ensuring high reliability in mission-critical applications.

-

-

Can the Honeywell 620-3030 handle large-scale data processing tasks?

-

Yes, it is optimized for large-scale data processing, making it suitable for complex industrial automation tasks.

-

-

What is the power supply requirement for the Honeywell 620-3030?

-

The module requires a 24V DC power supply, which is standard for industrial-grade equipment.

-

Related Models and Recommendations

Here are six related or recommended models from the same series or similar applications:

| Model | Description |

|---|---|

| 620-3020 | A processor module with enhanced data processing capabilities. |

| 620-3010 | A compact version of the processor module, ideal for smaller systems. |

| 620-3050 | High-performance module for demanding automation systems. |

| 620-3080 | Processor module with additional input/output support. |

| 620-3031 | A variant with improved communication protocols for high-speed applications. |

| 620-3005 | An energy-efficient module designed for remote operations. |

Additionally, here are six popular models:

| Model | Description |

|---|---|

| 10102/1/1 | Analog input module for industrial automation. |

| 10024/1/1 | Enhanced communication module for automated systems. |

| 07191/1/1 | RS485 communication board for remote system integration. |

| 10102/1/2 | Safety-related analog input module for secure operations. |

| 07170/1/1 | EPROM programmer with cable for system programming and diagnostics. |

| 07191/1/2 | Industrial communication board for various control systems. |

Excellent PLC

Excellent PLC