| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

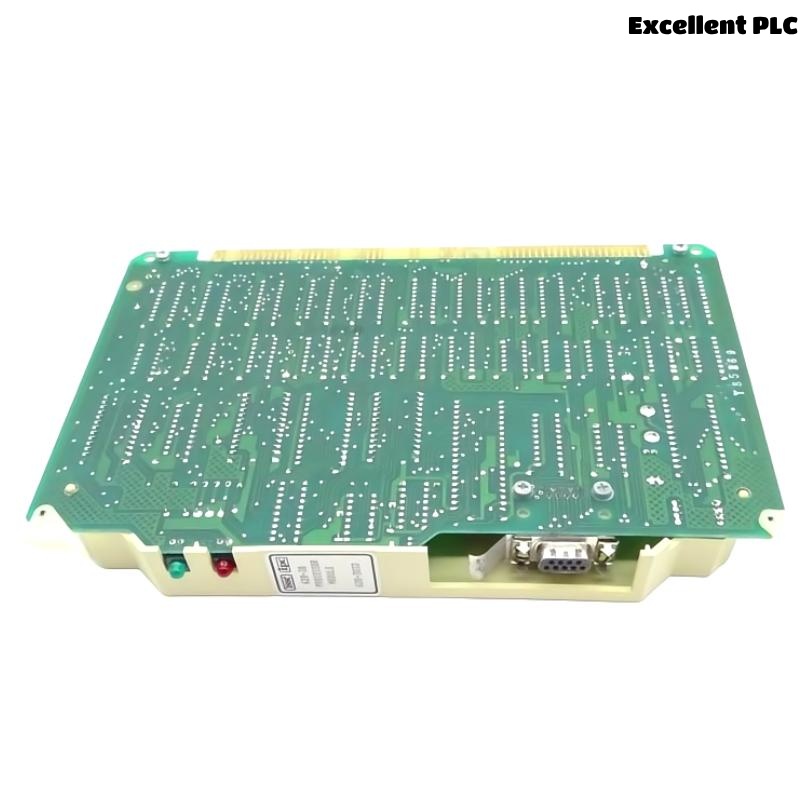

The Honeywell 620-3033 Processor Module is a core component of the Honeywell TDC 3000 Distributed Control System (DCS), engineered to perform real-time control and coordination of plant processes. Designed to be highly reliable and deterministic, this processor executes control logic, manages I/O traffic, and maintains communication with other system nodes including operator interfaces, peer controllers, and I/O subsystems.

As a legacy yet robust solution, the 620-3033 is still in wide use across various industries requiring critical and continuous process control. With its strong track record in uptime and resilience, the module ensures operational consistency in environments where every millisecond counts. Built for harsh industrial settings, it supports features like memory protection, fault detection, and redundancy options, which make it a trusted choice for large-scale industrial automation infrastructure.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | Honeywell 620-3033 |

| Product Type | Processor Module / Control Processor |

| System Compatibility | Honeywell TDC 3000 |

| Processor Type | Honeywell proprietary embedded processor |

| Memory | EPROM-based firmware and configurable RAM |

| Control Capability | Executes logic, PID, sequence, batch control |

| Communication Interface | Honeywell I/O Bus and peer controller network |

| Redundancy Support | Yes, supports redundant processor configurations |

| Diagnostics | Integrated system diagnostics with fault indicators |

| Input Voltage | 5 VDC supplied via system backplane |

| Hot Swap Capability | No; replacement requires safe system stop |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% RH, non-condensing |

| Mounting Type | Rack-mounted (standard TDC 3000 chassis) |

| Dimensions (W x H x D) | 165 x 280 x 51 mm |

| Weight | 0.449 kg |

| Certifications | CE, UL, CSA, ATEX Zone 2 (depending on system config) |

Product Applications

The Honeywell 620-3033 Processor Module is used in critical industrial automation environments where control precision, reliability, and system uptime are essential. Its applications include:

-

Oil and Gas Refining: Supervises complex process units, distillation columns, compressors, and emergency shutdown systems.

-

Power Plants: Controls boilers, turbines, and environmental monitoring systems in fossil and combined-cycle generation.

-

Pharmaceutical Production: Manages batch production, cleanroom environment controls, and GMP-compliant workflows.

-

Chemical Processing: Executes real-time control for reactors, heat exchangers, and separation columns.

-

Water and Wastewater Facilities: Operates pumps, chlorination units, and flow balancing stations with high accuracy.

-

Pulp and Paper Manufacturing: Handles continuous process loops for drying, pressing, and paper cutting lines.

Product Advantages

-

Proven Reliability: Built for uninterrupted operation in 24/7 production environments across global industries.

-

Integrated Diagnostics: Advanced internal health checks and status indicators reduce troubleshooting time.

-

High-Precision Control: Enables deterministic control execution for time-sensitive operations.

-

Redundancy Enabled: Can be deployed in redundant processor configurations to ensure fail-safe system behavior.

-

Legacy System Support: Seamlessly integrates with existing TDC 3000 infrastructure, protecting capital investment.

-

Secure Memory Architecture: EPROM-based firmware ensures program persistence even during power loss.

-

Field-Tested Durability: Operates reliably under extreme temperature, humidity, and vibration conditions.

-

Long Lifecycle: Supported under Honeywell’s lifecycle services and spare parts programs.

-

Broad Industry Compatibility: Can interface with a wide variety of industrial devices and control protocols.

-

Modular Rack Design: Enables simplified installation and replacement within existing cabinet frameworks.

Frequently Asked Questions (FAQ)

1. What is the main function of the 620-3033 Processor Module in a DCS system?

The module acts as the central controller, executing control logic, managing I/O data, and communicating with other system elements like operator stations and peer processors.

2. Can the 620-3033 operate as part of a redundant controller pair?

Yes. It supports fully redundant configurations where a backup processor automatically takes over in case the primary unit fails.

3. Is this processor hot-swappable?

No, the 620-3033 must be replaced during a planned shutdown. Live replacement is not supported due to system integrity constraints.

4. What type of logic can be executed on this processor?

It supports continuous control logic, batch sequencing, analog and digital control loops (PID), and alarm handling routines.

5. How is firmware stored and protected?

Firmware is typically stored in EPROM chips, providing resilience against power loss or accidental erasure.

6. What kind of diagnostics does the module support?

The processor includes onboard diagnostics to detect memory faults, communication issues, and hardware failures, which are reported to the system operator.

7. What environmental conditions can it safely operate in?

The unit is designed for standard industrial conditions, with operating temperatures from 0°C to 60°C and up to 95% humidity (non-condensing).

8. How is this module programmed or configured?

Programming is performed through Honeywell’s engineering workstation using tools designed for the TDC 3000 environment.

9. Can the 620-3033 interface with third-party systems?

Indirectly, yes. While it primarily communicates with Honeywell components, integration with external systems is possible via gateways and protocol converters.

10. How is communication with other system elements managed?

It communicates over Honeywell’s proprietary I/O bus and peer networks, facilitating real-time data exchange with operator stations, I/O modules, and other processors.

Related Models in the Same Series

| Model Number | Description | Function | System Compatibility |

|---|---|---|---|

| 620-1036 | I/O Multiplexer Module | Expands system I/O capacity | Honeywell TDC 3000 |

| 620-0085 | Analog Input Module | Analog signal acquisition | Honeywell TDC 3000 |

| 620-0086 | Analog Output Module | Outputs analog control signals | Honeywell TDC 3000 |

| 620-0080 | Digital Input Module | Binary input handling | Honeywell TDC 3000 |

| 620-0081 | Digital Output Module | Binary output control | Honeywell TDC 3000 |

| 620-0056 | I/O Link Interface | Connects I/O modules to processor | Honeywell TDC 3000 |

Popular Honeywell Models

| Model Number | Description | Platform | Purpose |

|---|---|---|---|

| CC-PAIN01 | Analog Input Module (Series C) | Experion PKS | High-accuracy process input |

| CC-TDIL01 | Digital Input Module | Experion PKS | Discrete field signal collection |

| CC-PCNT01 | Pulse Input Module | Experion PKS | Pulse/frequency signal processing |

| MU-TD0D12 | 24-Channel Digital Output Module | TDC 3000 | High-density output control |

| TC-CCR014 | Redundant Control Processor | Experion PKS | Real-time critical control |

| FC-SDO-0824 | Fail-Safe Digital Output Module | Safety Manager | Emergency shutdown control |

Excellent PLC

Excellent PLC