| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

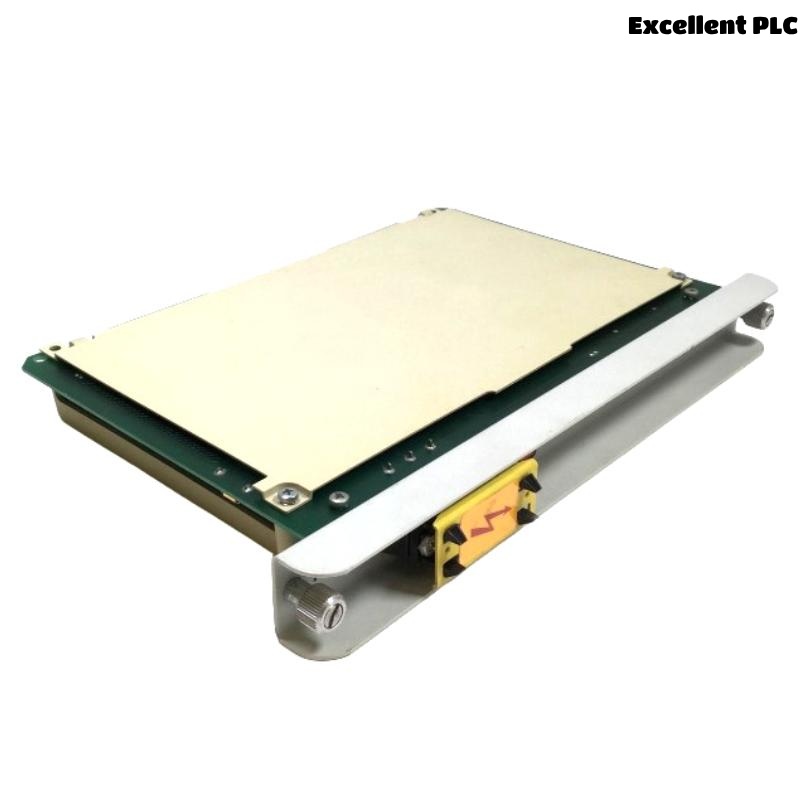

The Honeywell 621-1201 Enhanced Diagnostic Module is a critical component within the Honeywell TDC 3000 or Experion process control systems. Designed for high-availability industrial automation environments, this diagnostic module continuously monitors and assesses the status of I/O modules, control processors, and field devices.

Its main role is to provide real-time diagnostics and fault detection, allowing plant operators and maintenance teams to anticipate and prevent potential issues before they affect production. By improving system transparency, the 621-1201 enhances reliability, reduces downtime, and streamlines troubleshooting procedures across Honeywell DCS (Distributed Control System) infrastructures.

The module features robust firmware, high-speed data acquisition, and intelligent self-diagnostics capabilities. Its compact design and modular architecture allow it to be easily integrated or retrofitted into existing control cabinets.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Enhanced Diagnostic Module |

| Model Number | 621-1201 |

| Brand | Honeywell |

| System Compatibility | TDC 3000, Experion PKS |

| Primary Function | System diagnostics and fault detection |

| Supported Interfaces | I/O buses, processor communication paths |

| Data Refresh Rate | High-speed (up to 1 ms) |

| Power Supply Voltage | 24 VDC (regulated) |

| Mounting Type | Rack-mounted (DIN rail optional) |

| Communication Protocol | Proprietary Honeywell Diagnostic Bus |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| Protection Rating | IP20 (cabinet-installed) |

| Dimensions (L x W x H) | 145 x 100 x 40 mm |

| Weight | 0.55 kg |

| Compliance | CE, RoHS, UL certified |

Applications

The Honeywell 621-1201 module is widely used in industrial control and automation applications that demand high system availability and predictive maintenance. Key application areas include:

-

Petrochemical Plants: Continuous diagnostics of control loops and field devices in refining and chemical production units.

-

Power Generation Facilities: Monitoring of turbine control and boiler instrumentation systems.

-

Pharmaceutical Manufacturing: Ensures uninterrupted batch production and regulatory compliance.

-

Water Treatment Plants: Monitors instrumentation and process variables for 24/7 plant operation.

-

Pulp & Paper Mills: Identifies and isolates faults in process control loops to prevent process upsets.

-

Oil & Gas Terminals: Maintains data integrity and fault tolerance in high-risk areas.

Product Advantages

-

Real-Time Monitoring: Continuously checks system health, providing immediate alerts when anomalies are detected.

-

Minimized Downtime: Enables proactive maintenance, reducing the time required for troubleshooting.

-

Seamless Integration: Designed to plug directly into Honeywell control architectures without major reconfiguration.

-

Improved Safety: Detects faults that could lead to unsafe conditions, ensuring personnel and equipment protection.

-

Cost Efficiency: Reduces long-term maintenance costs by identifying problems before they escalate.

-

Modular Flexibility: Easily replaced or upgraded without affecting overall system performance.

Frequently Asked Questions (FAQ)

1. What does the Honeywell 621-1201 Enhanced Diagnostic Module monitor?

It monitors the operational status of control processors, I/O modules, and communication paths within Honeywell automation systems.

2. Is the module compatible with the latest Experion PKS systems?

Yes, it is backward and forward-compatible with both TDC 3000 and Experion PKS environments.

3. Can I install the 621-1201 in a third-party control system?

It is specifically designed for Honeywell DCS platforms and is not recommended for third-party systems.

4. Does it require any software configuration?

Initial setup is performed via the system console, but once configured, it operates autonomously and does not require frequent reprogramming.

5. What is the expected lifespan of this module?

Under typical conditions, it can operate reliably for over 10 years with minimal maintenance.

6. How does it help reduce unplanned downtime?

By continuously detecting anomalies and providing alerts before failures occur, the module allows maintenance to be scheduled proactively.

7. Is the diagnostic data accessible remotely?

Yes, through integration with the Honeywell system console or remote HMI, users can view real-time diagnostic data.

8. What happens if the module itself fails?

The system is designed to issue alerts if the diagnostic module is compromised, ensuring timely replacement.

9. How do I physically install the 621-1201?

It is mounted in a standard Honeywell system rack and requires no special tools or mounting hardware.

10. Does the module require routine calibration or testing?

No, it performs internal self-checks and is factory-calibrated. Routine functional testing can be scheduled based on site policy.

Related Models (Same or Related Series)

| Model | Part Number | Function | Compatibility |

|---|---|---|---|

| 621-1100 | 621-1100 | Basic Diagnostic Module | TDC 3000 |

| 621-2100 | 621-2100 | Power Supply Monitor | TDC 3000 / Experion |

| 621-1310 | 621-1310 | Enhanced Communication Module | TDC 3000 |

| 621-0650 | 621-0650 | Analog Input Module | TDC 3000 |

| 621-9930 | 621-9930 | Loop Controller Interface | TDC 3000 / Universal IO |

| 621-2200 | 621-2200 | Enhanced CPU Interface | Experion PKS |

Popular Honeywell Industrial Automation Modules

| Model | Part Number | Function | Application |

|---|---|---|---|

| CC-PDIL01 | 51405039-175 | Pulse Input Module | Safety Systems |

| CC-TAIX01 | 51405038-375 | Analog Input | Experion C300 |

| CC-TDIL01 | 51405040-175 | Digital Input | Process Control |

| MC-TDOD12 | 80363975-150 | Digital Output | Universal IO |

| 51304453-100 | 51304453-100 | Advanced Process Manager (APM) | TDC 3000 |

| CC-PCF901 | 51405047-100 | Fieldbus Power Conditioner | Field Device Integration |

Excellent PLC

Excellent PLC