| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

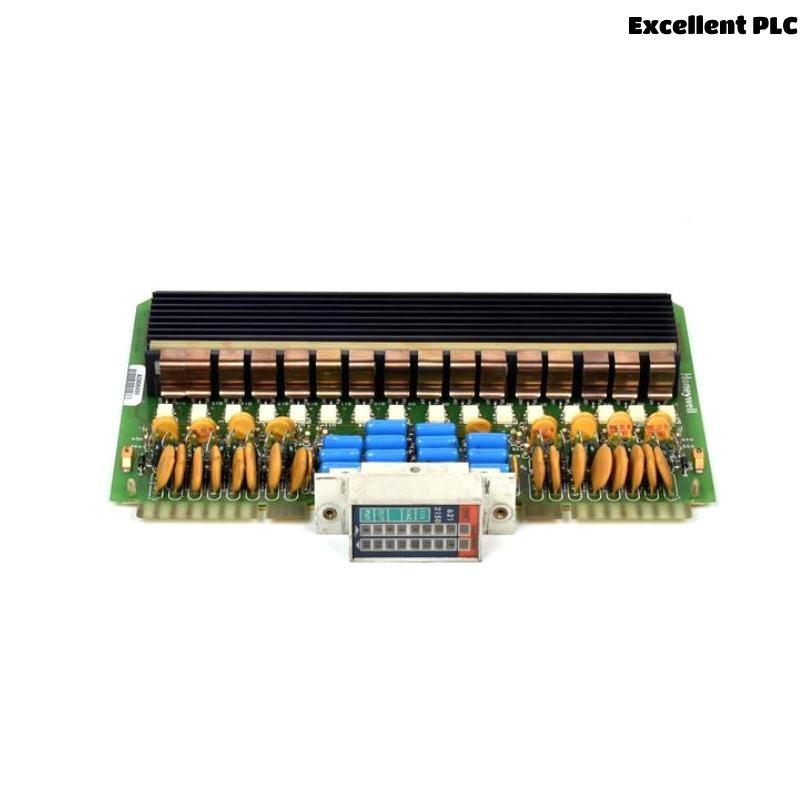

The Honeywell 621-2150 Output Module is a reliable and integral component in Honeywell’s widely respected TDC 2000 and TDC 3000 process control systems. Designed for high-performance industrial applications, this module delivers robust and precise output signal control, enabling the seamless integration and execution of automation commands. With a proven track record across multiple industries, the 621-2150 serves as a dependable digital output solution, making it suitable for controlling actuators, relays, solenoids, and various types of field devices.

As part of Honeywell’s legacy in process automation, the 621-2150 is engineered with durability and longevity in mind. The module is equipped with diagnostic functions that support fault detection and status reporting, ensuring continuous and safe system operations. Its modular design enables quick replacement and easy maintenance without system downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Honeywell 621-2150 Output Module |

| Type | Digital Output Module |

| Output Type | 16-Channel Discrete Output |

| Output Voltage | 24 VDC |

| Output Current | 0.5 A per channel (typical) |

| Isolation | Channel-to-logic and channel-to-channel isolation |

| Switching Time | < 1 ms |

| LED Indicators | Channel status LEDs (ON/OFF indication) |

| Mounting Style | DIN rail or card rack mounting |

| Dimensions (H × W × D) | 32 x 239 x 178 mm |

| Weight | 0.7 kg |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Certifications | CE, UL, CSA, FM |

Applications

The Honeywell 621-2150 Output Module is ideally suited for the following industrial applications:

-

Petrochemical Plants: For managing solenoids, pumps, and safety interlocks.

-

Power Generation: Used for turbine and boiler automation systems.

-

Water Treatment Facilities: Enables control of valves and dosing pumps.

-

Food and Beverage: Controls packaging machinery and conveyors.

-

Pharmaceutical Manufacturing: Used in automated batch and filling systems.

-

Paper and Pulp: Controls drives, agitators, and cutting machinery.

Its compatibility with legacy TDC systems makes it especially valuable for facilities undergoing upgrades without disrupting existing infrastructure.

Advantages

-

High Channel Density: Supports multiple outputs in a compact footprint.

-

Reliable Performance: Designed for continuous operation in harsh industrial conditions.

-

Status Monitoring: LED indicators offer at-a-glance operational diagnostics.

-

System Compatibility: Seamlessly integrates with Honeywell TDC 2000/3000 systems.

-

Reduced Downtime: Hot-swappable and easy to maintain.

-

Global Compliance: Certified for international safety and electromagnetic standards.

-

Longevity: Backed by Honeywell’s reputation for durable automation hardware.

-

Efficient Troubleshooting: Built-in diagnostics reduce maintenance time.

-

Scalability: Easily integrated into larger systems for future expansion.

-

Proven Legacy: Trusted by industries worldwide for decades.

Frequently Asked Questions (FAQ)

-

What is the primary function of the 621-2150 Output Module?

It provides 16 independent 24 VDC digital outputs to control actuators, relays, or other discrete field devices. -

Is this module suitable for use in hazardous industrial environments?

Yes, the module is designed with robust isolation and meets industrial safety certifications for harsh conditions. -

Can this module handle inductive loads like solenoids and motor starters?

Yes, it is capable of switching inductive loads, although external snubber circuits are recommended for high-energy devices. -

Does the module support per-channel diagnostics?

Yes, each output channel features an LED that indicates its operational status, simplifying fault detection. -

How is the module typically mounted in control systems?

It can be mounted on a DIN rail or slotted into a Honeywell system card rack, depending on system configuration. -

Is optical isolation provided for each channel?

Yes, each output channel includes optical isolation to prevent signal interference and enhance system safety. -

What type of control system architecture does the 621-2150 support?

It is compatible with Honeywell TDC 2000 and TDC 3000 control systems and may also integrate into hybrid DCS environments. -

What kind of field devices can be connected to the outputs?

You can connect devices like relays, solenoid valves, indicator lamps, contactors, and alarms. -

What happens if a channel experiences an overload?

The module includes short-circuit and overload protection that isolates the affected channel to avoid cascading faults. -

Can the 621-2150 be replaced while the system is running?

Yes, the module supports hot-swap capability, allowing for in-service replacement with minimal disruption.

Related Models from the Same Series or Family

| Model | Description |

|---|---|

| 621-1100 | Analog Input Module – 8 Channels |

| 621-2100 | Digital Input Module – 16 Channels |

| 621-2200 | Digital Input Module – High Voltage |

| 621-2300 | Digital Output Module – Relay Output |

| 621-9940 | Power Supply Module for TDC 2000/3000 |

| 621-0830 | Multiplexer Module – Analog Signal Routing |

Popular Honeywell Modules (Same Brand)

| Model | Description |

|---|---|

| TC-CCR013 | Controller Module for C300 Process System |

| CC-TDIL01 | Discrete Input Module – Universal I/O |

| CC-TDOR01 | Discrete Output Module – Universal I/O |

| CC-TAIX01 | Analog Input Module – HART-enabled |

| CC-PAOH01 | Analog Output Module for Series C |

| CC-PCNT01 | Pulse Counter Input Module |

Excellent PLC

Excellent PLC