| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

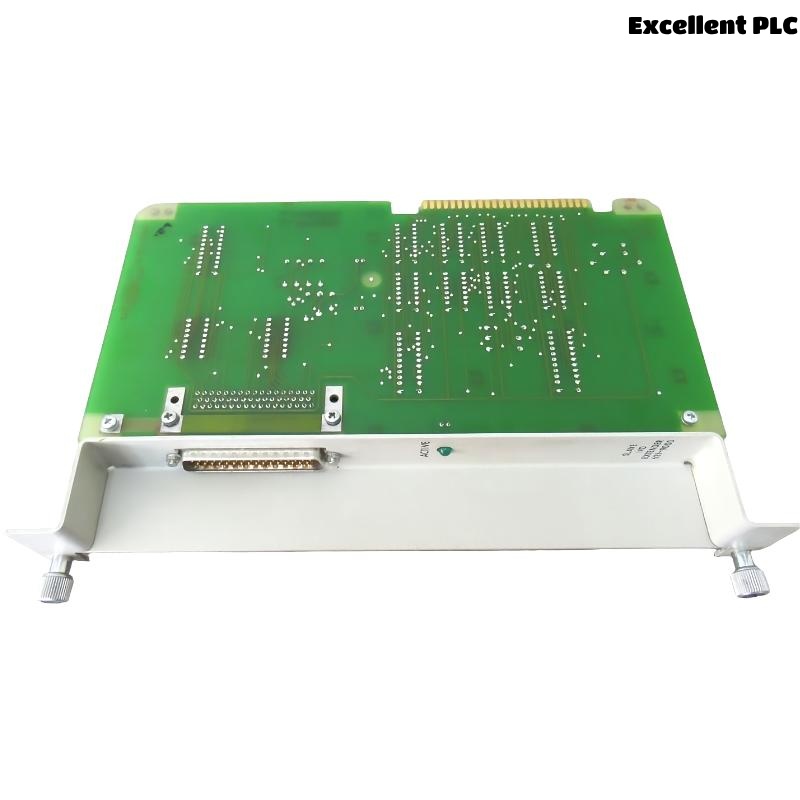

The Honeywell 621-9000 Slave I/O Extender Module is a critical part of Honeywell’s PlantScape and TPS (TotalPlant Solution) control architecture. This module enables the extension of local and remote I/O capabilities by acting as a communication and expansion interface between the controller and the connected I/O modules. It allows seamless integration of distributed I/O systems over long distances, supporting complex control strategies without sacrificing performance, reliability, or flexibility.

Designed to operate in demanding industrial environments, the 621-9000 module ensures high-speed data transfer, minimal latency, and robust fault isolation. It is particularly useful in large-scale process automation systems where control elements are dispersed over wide physical areas.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 621-9000 |

| Manufacturer | Honeywell |

| Module Type | Slave I/O Extender Module |

| Function | Slave communication interface for I/O extension |

| Communication Type | Redundant I/O LAN (RS-485-based proprietary protocol) |

| Data Transfer Rate | 1 Mbps (typical) |

| Max Distance (LAN) | Up to 1,500 meters with proper termination |

| Connection Type | Terminal block or fiber-optic depending on system |

| Compatibility | Honeywell 620 and 621 I/O systems |

| Power Supply | 5 VDC (from base unit) |

| Isolation | Optical/electrical isolation on communication lines |

| LED Indicators | Status, communication, fault |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN rail or chassis rack |

| Certifications | CE, UL, CSA |

| Dimensions (H x W x D) | 120 x 35 x 110 mm |

| Weight | 0.23 kg |

Product Applications

The Honeywell 621-9000 module is widely used in industrial automation environments where extended I/O networks are required. It is particularly suitable for:

-

Refineries & Petrochemical Plants – Enables long-distance signal integration across distributed plant units.

-

Power Generation Facilities – Connects control modules across different control rooms or turbine floors.

-

Chemical Processing Plants – Expands digital and analog I/O for complex control sequences.

-

Pharmaceutical Manufacturing – Links remote instrumentation without introducing noise or latency.

-

Water Treatment Plants – Connects sensor clusters and actuators spread over large facilities.

-

Pulp & Paper Industry – Facilitates remote monitoring of process equipment in multi-level buildings.

Product Advantages

-

Extended I/O Capabilities: Seamlessly expands I/O beyond local limitations without signal degradation.

-

Robust Communication: Uses a fault-tolerant proprietary RS-485 protocol optimized for industrial use.

-

System Scalability: Supports large system configurations with multiple I/O racks.

-

Hot Diagnostics: Real-time diagnostics through LEDs and integrated system alerts.

-

High Compatibility: Fully integrates with Honeywell 620/621 series, and legacy TPS environments.

-

Noise Immunity: Optical and electrical isolation ensures clean data transmission in harsh environments.

-

Minimal Latency: Maintains control responsiveness even with extended communication paths.

FAQ

-

What communication protocol does the 621-9000 module use?

It uses a proprietary RS-485-based protocol over a redundant I/O LAN for high-integrity communication. -

Is the 621-9000 module hot-swappable?

No, power must be turned off before installing or replacing the module to avoid system errors. -

Can the module operate in redundant configurations?

Yes, it supports redundant I/O LAN paths for high-availability applications. -

Does it require termination resistors?

Yes, proper termination is necessary at the ends of the RS-485 LAN to prevent signal reflection. -

Is the module compatible with fiber optic LANs?

Yes, with additional Honeywell transceivers or converters, it can work over fiber-optic media. -

What is the maximum number of I/O modules supported through one 621-9000?

This depends on system configuration, but typically supports 31 nodes per segment. -

How does the module indicate communication loss?

Through dedicated status and fault LEDs and system diagnostic messages. -

Does the module buffer data if LAN communication is interrupted?

No, it does not buffer; real-time communication is required for control updates. -

Can multiple 621-9000 modules be used in the same I/O network?

Yes, they are designed to work in multi-module distributed architectures. -

What type of electrical isolation is implemented?

Optical isolation is provided on communication interfaces to protect against ground loops and transients.

Related Models (Same Series or Function)

| Model | Description | Function | I/O Support |

|---|---|---|---|

| 621-9930 | Local I/O Bus Interface | Primary I/O link driver | Up to 8 I/O modules |

| 621-1100 | Analog Input Module (8-channel) | AI module | 4–20 mA / RTD |

| 621-2200 | Digital Input Module (16-channel) | DI module | 24 VDC inputs |

| 621-2210 | Digital Output Module (16-channel) | DO module | 24 VDC outputs |

| 621-3400 | RTD Input Module | Temperature sensing | RTD (Pt100) inputs |

| 621-2100 | Relay Output Module | High-power switching | SPDT relay outputs |

Popular Honeywell Models

| Model | Description | Type | Application |

|---|---|---|---|

| C300 Controller | Core controller for Experion PKS | Distributed Controller | Process Automation |

| HC900 Controller | Modular hybrid control system | Process/Logic Controller | Batch/Hybrid Systems |

| STT750 | Smart Temperature Transmitter | Field Transmitter | Temperature Measurement |

| SMV3000 | Multivariable Pressure Transmitter | Flow/Pressure Measurement | Flow Control |

| UDC3500 | Universal Digital Controller | Single-loop PID Controller | Temperature/Process Control |

| FSC (TMR) | Fault Tolerant Safety Controller | Safety PLC | SIL 3 Safety Applications |

Excellent PLC

Excellent PLC