| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

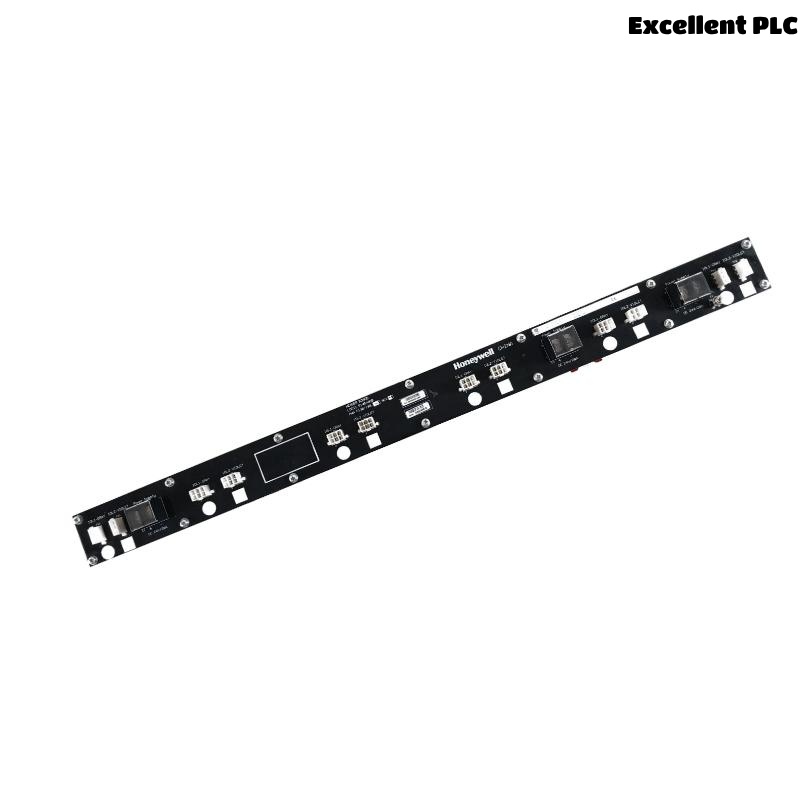

The Honeywell 8C-SHEDA1 51307186-175 Header Board is an integral component of Honeywell’s Experion Process Knowledge System (PKS), designed to interface with signal termination assemblies in industrial automation environments. This module functions as a backplane connection point for field I/O signals, ensuring reliable data transmission between process inputs/outputs and the control system.

Built to support high-density signal wiring and designed with robust industrial-grade materials, the 8C-SHEDA1 header board offers exceptional durability, electrical performance, and easy integration into Honeywell’s C300 and Series 8 I/O architecture. It is essential for distributed control systems (DCS) where efficiency, reliability, and maintainability are critical.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 8C-SHEDA1 |

| Part Number | 51307186-175 |

| Product Type | Header Board |

| System Compatibility | Honeywell Series 8 / C300 Controller Systems |

| Functionality | Signal routing and termination |

| Material | High-grade PCB with protective conformal coating |

| Connection Type | Screw or plug-in terminal block (depending on configuration) |

| Operating Voltage | 24V DC (nominal) |

| Operating Temperature Range | -20°C to +70°C (-4°F to +158°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Humidity Tolerance | 5% to 95% non-condensing |

| Mounting Type | DIN Rail / Panel Mount |

| Dimensions (L x W x H) | 210 x 130 x 30 mm |

| Weight | 0.45 kg |

| Certifications | CE, UL, RoHS |

Product Applications

The Honeywell 8C-SHEDA1 51307186-175 header board is widely used across various industries due to its reliability and integration capabilities:

-

Oil & Gas: As part of critical safety systems and real-time process monitoring in upstream and downstream operations.

-

Power Generation: Integrated into turbine and generator control systems for efficient process regulation.

-

Pharmaceuticals: Supports validated environments requiring high accuracy and signal integrity.

-

Chemicals & Petrochemicals: Ensures safe control of complex process sequences.

-

Pulp & Paper: Handles signal routing for high-speed automation systems.

-

Water & Wastewater Treatment: Interfaces with remote I/O for system-wide monitoring and control.

Product Advantages

-

High Integration with Honeywell Systems: Seamless compatibility with C300 and Series 8 controllers enhances control reliability.

-

Compact, Space-Efficient Design: Designed to optimize cabinet space with DIN rail mounting support.

-

Rugged and Reliable Construction: Built to handle harsh industrial environments with conformal coating for added protection.

-

Simplified Wiring and Maintenance: Easy terminal access facilitates faster installation and replacement cycles.

-

Enhanced Signal Integrity: Designed for low-noise, high-fidelity signal transmission critical in analog/digital I/O applications.

-

Field-Proven Stability: Used in thousands of installations worldwide with a strong record of durability and reliability.

-

Future-Proof Compatibility: Part of Honeywell’s forward-compatible control system design strategy.

-

Easy Replacement: Hot-swappable or easily replaced during shutdowns without extensive rewiring.

-

Certified for Global Use: Compliant with international standards for safety and environment.

-

Support for Redundancy: Allows redundancy and fault-tolerant architecture where system uptime is crucial.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Honeywell 8C-SHEDA1 header board?

It serves as a termination and routing interface between field devices and the Honeywell control system. -

Is this board compatible with other Honeywell platforms outside of Series 8?

It is primarily designed for the Series 8 I/O modules and C300 controllers, though it may work with compatible legacy systems. -

Can the board be mounted on any standard DIN rail?

Yes, it supports standard DIN rail mounting for easy installation. -

Does it require any special software for configuration?

No software configuration is needed; it’s a passive hardware interface. -

Is it safe for use in hazardous areas?

With proper enclosure and certifications, it can be deployed in classified industrial zones. -

How many I/O channels does it support?

The specific channel count depends on the I/O module used in conjunction with the header board. -

Can this board be replaced without shutting down the whole system?

It depends on system configuration; in redundant architectures, replacement may be possible without downtime. -

What type of field signals can it handle?

Both digital and analog I/O signals depending on the paired I/O modules. -

Is technical documentation available for field engineers?

Yes, we provide detailed user manual and wiring guide. -

How long is the typical service life of this board?

With proper usage and environment, it can exceed 10 years of continuous service.

Recommended Related Models (Same Series or Functionality)

| Model Number | Description |

|---|---|

| 8C-TAIX61 | Analog Input Terminal Assembly |

| 8C-TDOD61 | Digital Output Terminal Assembly |

| 8C-PAINA1 | Power Input Assembly for Series 8 |

| 8C-PDODA1 | Digital Output Baseplate Assembly |

| 8C-TDIL51 | Digital Input Assembly with LED Indication |

| 8C-PAOHA1 | Output Header Assembly for I/O connections |

Popular Honeywell Models (Same Brand, Different Use)

| Model Number | Description |

|---|---|

| CC-PDOB01 | Digital Output Module for C300 Controller |

| CC-TDIL01 | Digital Input Module with LED and diagnostics |

| FC-SDI-1624 | Safety Digital Input Module, SIL-rated |

| 51401491-100 | High-Performance Network Interface Module |

| 51204172-175 | PMIO Power Supply Module |

| CC-TAOX01 | Analog Output Module for critical control applications |

Excellent PLC

Excellent PLC