| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

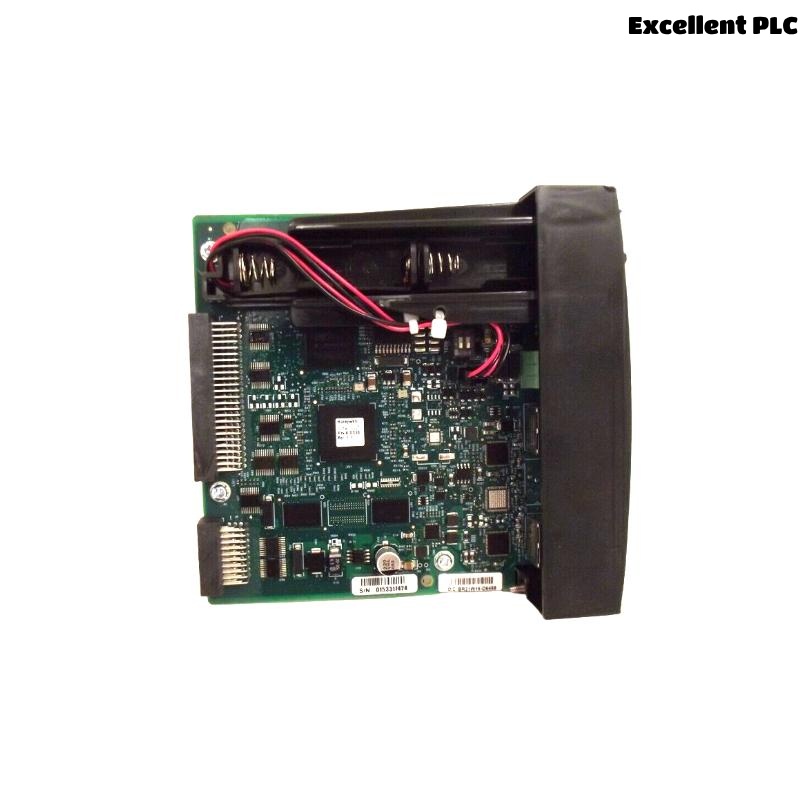

The Honeywell 900C30S-0460 is a high-performance HC900 C30 Controller CPU, specifically designed for complex process automation and hybrid control applications. Part of the HC900 family, this model provides modularity, scalability, and powerful logic processing capabilities in a compact and efficient package. It is ideal for industries requiring precise control, data acquisition, and reliable performance in harsh industrial environments.

This C30 CPU variant supports broad connectivity, integrates seamlessly with I/O modules and operator stations, and is engineered to control up to hundreds of analog and digital I/O points. Whether for thermal processing, batch production, or environmental monitoring, the 900C30S-0460 delivers trusted Honeywell quality and performance at the core of process automation systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C30S-0460 |

| Product Type | HC900 C30 Controller CPU |

| Series | Honeywell HC900 Hybrid Control System |

| CPU Type | C30 (Compact CPU) |

| Memory | 10 MB non-volatile memory |

| I/O Capacity | Up to 960 I/O points |

| Supported I/O Types | Analog In/Out, Digital In/Out, Thermocouples, RTDs |

| Scan Rate | Typically 25 ms per 100 PID loops |

| Programming Interface | Ethernet via Hybrid Control Designer (HCD) |

| Communications | Modbus TCP, Serial Modbus RTU, Peer-to-Peer, OPC via Experion |

| Redundancy Support | Not supported (single CPU only) |

| Power Supply Input | 24 VDC |

| Mounting Type | DIN Rail |

| Operating Temperature Range | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity Range | 5% to 95% RH, non-condensing |

| Shock/Vibration Resistance | IEC 60068 compliant |

| Certifications | CE, UL, CSA, FM, ATEX Zone 2, Class 1 Div 2 |

| Dimensions (HxWxD) | 89 × 56 × 46 mm |

| Weight | 0.54 kg |

| Programming Software | Honeywell Hybrid Control Designer |

Product Applications

The Honeywell 900C30S-0460 is widely used in industrial process automation, especially in hybrid process environments that demand integrated logic, control, and communication. Applications include:

-

Thermal Processing Control

Used in kilns, furnaces, dryers, and ovens for precise temperature management. -

Water and Wastewater Management

Pump control, valve sequencing, and flow monitoring in municipal and industrial plants. -

Pharmaceutical and Chemical Plants

Supports batch processing, clean-in-place (CIP), and recipe-based operations. -

Food and Beverage Production

Manages fermentation, cooking, blending, and sanitation processes. -

Boiler and Utility Systems

Controls steam generation, fuel feed, and burner sequences. -

Environmental Monitoring Systems

Integrates air and emissions monitoring with automated regulatory reporting.

Product Advantages

-

Compact, Modular Architecture

Allows flexible system configuration and future expansion while conserving panel space. -

High-Speed Loop Execution

Capable of handling fast control loops and real-time process updates. -

Reliable Industrial Design

Designed for long-term deployment in hazardous and mission-critical environments. -

Open Connectivity

Communicates seamlessly with SCADA, HMI, DCS, and third-party devices via standard protocols. -

Intuitive Configuration Software

Honeywell’s HCD tool offers drag-and-drop configuration, diagnostics, and simulation. -

Scalable Control

Supports a wide range of I/O modules and control strategies to suit both small and large systems. -

Global Compliance

Certified for use in hazardous locations and compliant with international automation standards.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between 900C30S-0460 and other C30 models?

A: The 0460 variant may include updated firmware or specific configuration tailored for broader application requirements compared to earlier C30 versions. -

Q: Can this CPU be used in safety-critical applications?

A: No, the 900C30S-0460 is not SIL-rated. For safety applications, use Honeywell’s HC900 Safety controllers. -

Q: What is the maximum number of I/O points supported?

A: This controller supports up to 960 I/O points depending on the rack and modules used. -

Q: Does the C30 support redundant CPU operation?

A: No, redundancy is not available on the C30. The C70 model offers redundancy. -

Q: How do I program this controller?

A: Use Honeywell’s Hybrid Control Designer software via Ethernet connection. -

Q: Is it compatible with SCADA or DCS systems?

A: Yes, it supports Modbus TCP/RTU and OPC via integration with Honeywell Experion or other SCADA systems. -

Q: What power supply is required?

A: It operates on 24 VDC input power. -

Q: Can I use it in explosive environments?

A: Yes, the unit is certified for Class 1 Div 2 and ATEX Zone 2 installations. -

Q: Is remote I/O supported?

A: Yes, remote I/O expansion is supported via Honeywell’s 900R modules. -

Q: What happens during a power failure?

A: The controller retains non-volatile memory and resumes operation upon power restoration.

Related or Same-Series Honeywell Models

| Model | Description | CPU Type | Redundancy | I/O Capacity |

|---|---|---|---|---|

| 900C30S-0360 | Standard C30 CPU | C30 | No | Up to 960 |

| 900C50S-0100 | High-capacity CPU | C50 | No | Up to 1920 |

| 900C70R-0100 | Redundant CPU Controller | C70 | Yes | Up to 4000 |

| 900R200A-0100 | Remote I/O Rack Controller | – | – | I/O Extension |

| 900A16-0101 | 16-Channel Analog Input Module | – | – | – |

| 900B32-0101 | 32-Channel Digital Output Module | – | – | – |

Popular Honeywell Industrial Automation Models

| Model | Product Name | Application | Communication |

|---|---|---|---|

| C300 Controller | Experion PKS Distributed Controller | Advanced DCS Systems | FTE, ControlNet |

| HC900-C70R | Redundant Hybrid Controller | Safety & Critical Processes | Ethernet, Modbus TCP |

| UDC3500 | Universal Digital Controller | Loop & PID Control | Ethernet, RS485, Modbus |

| ML200 Series | Modular Logic Controllers (PLCs) | Machine & OEM Control | Ethernet, Serial |

| ControlEdge PLC | Edge Programmable Logic Controller | Connected Plant Automation | OPC UA, MQTT |

| HC900 Safety System | Safety-Certified Controller (SIL3) | Safety Instrumented Functions | SafetyNet, Modbus |

Excellent PLC

Excellent PLC