| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

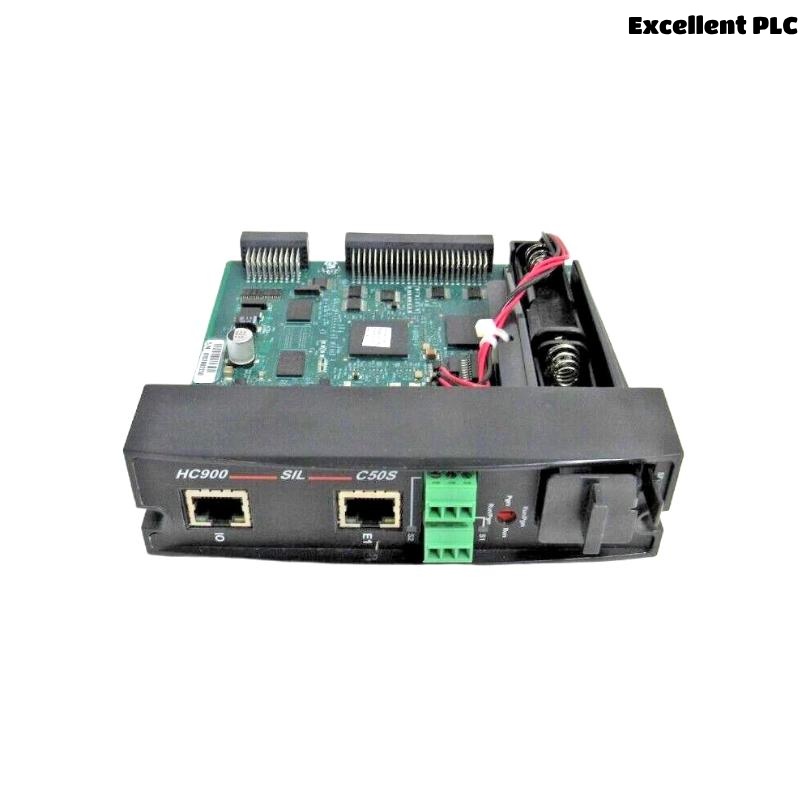

The Honeywell 900C50S-0460 HC900 C50 Controller CPU is an advanced industrial control unit designed to manage complex control systems in various industries. It is part of the Honeywell HC900 series, a proven solution for both discrete and continuous control, offering high flexibility and scalability. The C50 Controller CPU is known for its precision in managing critical processes and ensuring smooth operation of machinery in demanding environments.

This model integrates seamlessly with Honeywell’s HC900 Process Automation System, providing superior data processing and real-time control for applications in industries like power generation, chemical processing, water treatment, food and beverage, and many others. The 900C50S-0460 CPU ensures both reliability and efficiency in controlling and monitoring system performance, optimizing energy usage, and improving overall operational efficiency.

With robust communication options, high-speed processing capabilities, and an intuitive user interface, the HC900 C50 Controller CPU is an ideal choice for companies looking to modernize and enhance their process control systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 900C50S-0460 |

| Product Type | HC900 C50 Controller CPU |

| Processor Type | Dual-core high-performance processor |

| Communication Protocols | Ethernet, Modbus TCP, RS-232, RS-485, USB |

| Operating Voltage | 24 VDC |

| I/O Capacity | Up to 1,024 I/O points |

| Memory | 32 MB RAM (expandable) |

| Dimensions (L x W x H) | 137 × 38.1 × 137.16 mm |

| Weight | 0.36 kg |

| Operating Temperature | 0°C to 60°C |

| Mounting | DIN rail or panel mount |

| Redundancy Support | Yes, supports redundant configurations for high availability |

| Power Supply | 24 VDC with 10% tolerance |

| Compatibility | Compatible with other HC900 series devices and Honeywell systems |

| Certifications | CE, UL, RoHS |

Applications

The Honeywell 900C50S-0460 HC900 C50 Controller CPU is designed for a wide variety of applications in industries that require precise control and monitoring. Some of its key applications include:

-

Process Automation: Used to control continuous and batch processes in manufacturing, chemical processing, and water treatment facilities.

-

Energy Management: Employed in power generation and distribution systems, helping optimize energy usage and manage power equipment efficiently.

-

Oil and Gas: Ideal for managing the performance of machinery and systems in the oil and gas industry, including pumps, compressors, and turbines.

-

Food and Beverage: Ensures consistent and efficient operation of food production processes, from mixing and batching to packaging.

-

Pharmaceutical Manufacturing: Monitors temperature, pressure, and other critical parameters in pharmaceutical plants to ensure safety and regulatory compliance.

-

Water Treatment: Used in water treatment plants for monitoring chemical dosing, filtration, and flow management.

Advantages

-

High Performance: Equipped with a dual-core processor for fast data processing and real-time control, ensuring precise and efficient process management.

-

Scalable System: Supports up to 1,024 I/O points, allowing for scalable solutions in large or complex systems.

-

Redundancy Support: Provides system redundancy for high availability, ensuring continuous operation even in case of failure, which is critical in industrial control applications.

-

Flexible Communication Options: Supports multiple communication protocols including Ethernet, Modbus TCP, RS-232, RS-485, and USB, making it highly adaptable to existing systems.

-

Large Memory Capacity: With 32 MB of RAM, it handles large datasets and complex control processes without performance degradation.

-

User-Friendly Interface: The intuitive configuration and operation interface makes setup and ongoing maintenance simpler for operators.

-

Compact and Robust Design: The CPU has a compact footprint, yet it is built to withstand the harsh conditions of industrial environments.

-

Energy Efficiency: Optimized power consumption to reduce operational costs while maintaining peak performance.

-

Reliable and Durable: Built to meet industrial standards, this controller CPU ensures long-term reliability and robustness under extreme conditions.

-

Wide Industry Compatibility: It integrates seamlessly with the HC900 series and other Honeywell systems, offering flexibility for a variety of industrial applications.

Frequently Asked Questions (FAQs)

1. What is the Honeywell 900C50S-0460 HC900 C50 Controller CPU used for?

The 900C50S-0460 is used to manage complex control processes in industries such as power generation, oil and gas, chemical processing, and water treatment.

2. What communication protocols does this CPU support?

It supports Ethernet, Modbus TCP, RS-232, RS-485, and USB communication protocols, allowing seamless integration into a variety of industrial networks.

3. What is the I/O capacity of this controller?

It supports up to 1,024 I/O points, making it suitable for large and complex systems that require multiple input and output signals.

4. How much memory does the HC900 C50 Controller CPU have?

The CPU has 32 MB of RAM, which is expandable to accommodate larger control systems and more complex processes.

5. Can the Honeywell 900C50S-0460 be used in harsh environments?

Yes, it is built to withstand a wide range of industrial conditions, with an operating temperature range of 0°C to 60°C, making it suitable for many demanding environments.

6. What is the power supply requirement for this CPU?

It requires a 24 VDC power supply with a 10% tolerance.

7. Can the HC900 C50 Controller CPU be used in redundant configurations?

Yes, it supports redundancy configurations, ensuring high availability for critical applications that require continuous operation.

8. What industries can benefit from the Honeywell HC900 C50 Controller CPU?

Industries such as manufacturing, power generation, chemical processing, oil and gas, food and beverage, and pharmaceuticals can all benefit from its high-performance capabilities.

9. How is the Honeywell 900C50S-0460 mounted?

It can be mounted on a DIN rail or directly on a panel for flexibility in installation.

10. Is this CPU compatible with other Honeywell systems?

Yes, it is fully compatible with other Honeywell HC900 series devices and other Honeywell control systems.

Related Models from the Same Series

| Model Number | Description | I/O Capacity | Memory | Weight |

|---|---|---|---|---|

| 900C50S-0461 | HC900 C50 Controller CPU (with higher memory) | 1,024 I/O | 64 MB RAM | 2.1 kg |

| 900C50S-0462 | HC900 C50 Controller CPU (with enhanced performance) | 1,024 I/O | 32 MB RAM | 2.0 kg |

| 900C50S-0463 | HC900 C50 Controller CPU (with additional I/O support) | 1,536 I/O | 32 MB RAM | 2.3 kg |

| 900C50S-0464 | HC900 C50 Controller CPU (with dual processor) | 1,024 I/O | 32 MB RAM | 2.2 kg |

| 900C50S-0465 | HC900 C50 Controller CPU (with expanded communication options) | 1,024 I/O | 32 MB RAM | 2.0 kg |

| 900C50S-0466 | HC900 C50 Controller CPU (basic version) | 512 I/O | 16 MB RAM | 1.8 kg |

Popular Honeywell Models

| Model Number | Description | Application | Weight |

|---|---|---|---|

| 900C32S-0141-00 | HC900 C30 Controller CPU | Industrial process control | 1.5 kg |

| 900C32S-0141-01 | HC900 C30 Controller CPU (with additional I/O) | Process automation | 1.7 kg |

| 900C32S-0141-02 | HC900 C30 Controller CPU (with redundancy) | Energy management | 1.6 kg |

| 900C32S-0141-03 | HC900 C30 Controller CPU (compact model) | Manufacturing control | 1.4 kg |

| 900C32S-0141-04 | HC900 C30 Controller CPU (high-performance version) | Oil and gas automation | 1.8 kg |

| 900C32S-0141-05 | HC900 C30 Controller CPU (advanced control) | Food and beverage | 2.0 kg |

Excellent PLC

Excellent PLC