| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

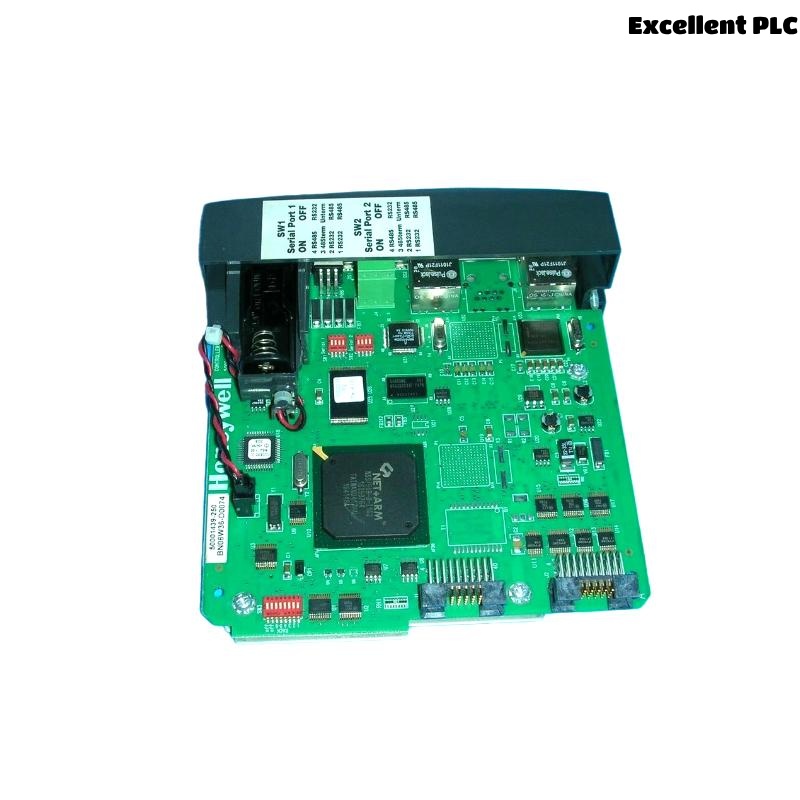

The Honeywell 900C51-0141-00 HC900 C50 Controller CPU is a robust and high-performance controller module designed for hybrid control applications that require a seamless integration of process, logic, and safety functions. As part of the HC900 Process and Safety System, the C50 CPU plays a central role in managing complex industrial operations, combining ease of configuration with reliable and scalable control.

Targeted at process industries such as chemical processing, water treatment, food production, and energy, this controller supports flexible I/O structures and open communication protocols. It’s well-suited for both standalone and networked installations. The 900C51-0141-00 model provides enhanced memory and connectivity features, enabling efficient and centralized control over thousands of input/output points.

Honeywell’s HC900 platform is known for its high integrity, fast performance, and powerful engineering tools—all designed to reduce operational costs, increase uptime, and ensure compliance with industrial safety standards.

Product Specifications

| Specification | Details |

|---|---|

| Model | 900C51-0141-00 |

| Series | HC900 |

| Controller Type | C50 CPU Module |

| Processor | 32-bit high-speed CPU |

| RAM | 32 MB |

| Flash Memory | 16 MB |

| Control Strategy Storage | 8 MB |

| I/O Support | Up to 4,000 I/O points |

| Loop Control Capability | Up to 100 PID loops |

| Redundancy | Supported (CPU, Power, Comms optional) |

| Supported Protocols | Modbus TCP/IP, Modbus RTU, OPC, Ethernet/IP |

| Ports | 2 x 10/100 Mbps Ethernet, 1 x RS-232/485 |

| Scan Rate | 5 ms typical |

| Operating Voltage | 24 VDC nominal |

| Mounting Type | DIN Rail Mounting |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Certifications | UL, CE, CSA, RoHS |

| Dimensions (W x H x D) | 50 x 30 x 20 mm |

| Weight | 0.15 kg |

Product Applications

The 900C51-0141-00 HC900 C50 Controller is engineered for high-integrity industrial control and automation tasks across a wide range of industries. Its advanced features make it suitable for:

-

Batch and Continuous Processing Plants: Flexible logic and PID loop control for mixing, blending, and sequencing operations.

-

Thermal Control Systems: Ideal for ovens, furnaces, kilns, and autoclaves requiring multi-zone temperature control.

-

Water and Wastewater Treatment: Real-time control for flow, pressure, level, and chemical dosing systems.

-

Food and Beverage Processing: Maintains precise thermal and process parameters to ensure product quality and regulatory compliance.

-

Power Generation: Supports boiler control, fuel systems, emissions monitoring, and safety functions.

-

Pharmaceutical Manufacturing: Ensures temperature and process reliability for validation-critical environments.

Product Advantages

-

Integrated Hybrid Control: Combines process, logic, and safety control within one platform to reduce complexity.

-

Modular and Scalable Design: Supports system expansion without replacing the core controller.

-

Fast Execution Time: 5 ms scan rate ensures rapid processing of logic and control commands.

-

Wide Communication Support: Facilitates easy integration with SCADA, DCS, HMIs, and third-party PLCs via Modbus, OPC, and Ethernet/IP.

-

Robust Data Logging: Built-in historical data logging and trend recording for diagnostics and compliance.

-

Redundancy for Reliability: Optional CPU and communication redundancy ensures system uptime.

-

Efficient Engineering Tools: HC900 Control Builder provides drag-and-drop configuration with minimal coding.

-

Secure Operations: Equipped with secure firmware, user roles, and access management features.

-

Reduced Maintenance Downtime: Diagnostic alerts and real-time health monitoring enhance maintainability.

-

Industrial Grade Build: Withstands wide temperature ranges and harsh conditions thanks to rugged design.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between the 900C51-0141-00 and earlier C50 models?

A: The 900C51-0141-00 features increased memory, improved firmware capability, and expanded communication options. -

Q: Does this controller support redundancy?

A: Yes, the controller supports redundancy in CPU, power, and network configurations. -

Q: What programming tool is used for this CPU?

A: The Honeywell HC900 Control Builder is used for configuration, monitoring, and diagnostics. -

Q: Is the controller suitable for high-speed applications?

A: Yes, with a typical 5 ms scan rate, it’s suitable for fast control tasks and time-sensitive loops. -

Q: How many I/O modules can it manage?

A: It can manage up to 4,000 I/O points depending on system configuration. -

Q: Can I use this controller in a hazardous environment?

A: The controller is not intrinsically safe by itself, but it can be used with hazardous-area I/O modules. -

Q: What industrial protocols are supported?

A: Modbus TCP/IP, Modbus RTU, OPC, and Ethernet/IP are supported for extensive connectivity. -

Q: What are the mounting requirements?

A: It is designed for DIN rail mounting within control enclosures or panels. -

Q: What is the maximum number of control loops supported?

A: The CPU supports up to 100 individual PID loops for process control. -

Q: Is this controller part of a larger automation system?

A: Yes, it is the core controller within the HC900 hybrid control system, integrating with Honeywell or third-party I/O, HMIs, and SCADA systems.

Recommended Related Models (Same Series or Compatible)

| Model | Description | Key Features |

|---|---|---|

| 900C51-0124-00 | HC900 C50 CPU | Standard version with base memory |

| 900C52-0001-00 | HC900 C70 Redundant Controller | Designed for high-availability systems |

| 900P01-0101 | Power Supply Module | 24 VDC input, for C50 and other modules |

| 900R12-0101 | Remote I/O Module | Supports distributed I/O over Ethernet |

| 900TC-0001 | Thermocouple Input Module | Handles direct TC signal processing |

| 900RTD-0001 | RTD Input Module | Supports temperature input via RTDs |

Popular Honeywell Models (Same Brand)

| Model | Description | Application |

|---|---|---|

| UDC3500 | Universal Digital Controller | Single-loop control in process plants |

| STG700 | Smart Pressure Transmitter | Accurate field pressure measurement |

| Experion LX | Small DCS System | Ideal for batch and hybrid processes |

| SLATE Combustion | Burner Management System | Flame safeguard and combustion control |

| HC900-C70 | HC900 Redundant CPU | Large-scale hybrid control |

| ControlEdge PLC | Programmable Logic Controller | IIoT-enabled edge control applications |

Excellent PLC

Excellent PLC