| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

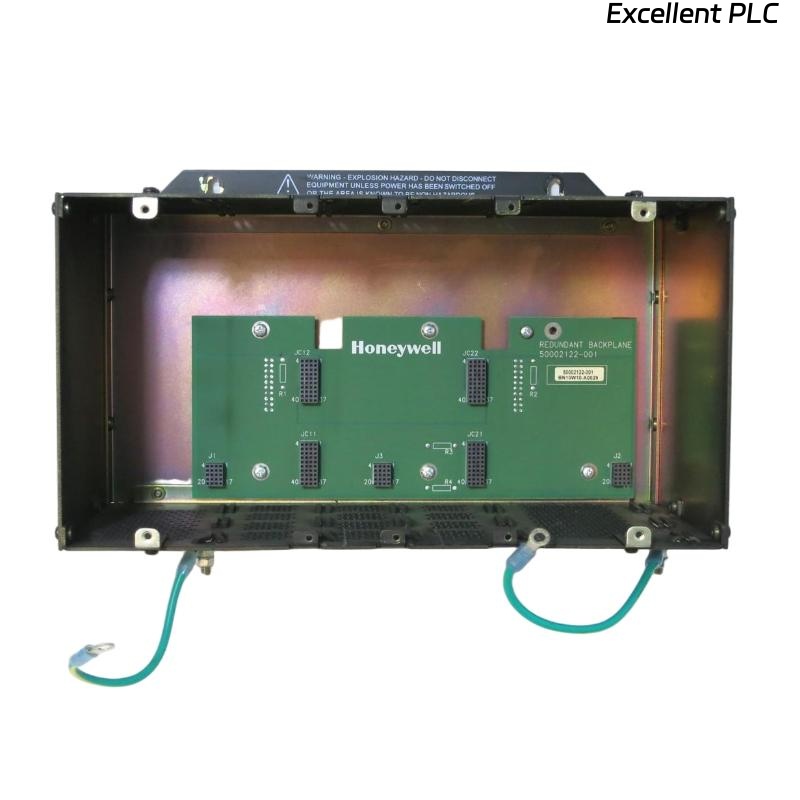

The Honeywell 900R4-0200 4-Slot I/O Rack is an essential component in Honeywell’s distributed control systems (DCS) and industrial automation applications. This rack is designed to house up to four I/O modules, enabling seamless integration of input and output devices into Honeywell’s advanced control and monitoring systems. The 900R4-0200 is engineered for reliability and high-performance in industrial environments, offering scalable and flexible I/O solutions for a wide range of process control applications.

As part of Honeywell’s R-series, the 900R4-0200 is highly modular, allowing users to easily configure their systems based on specific needs. The compact yet robust design ensures reliable performance and long-term durability, while the flexibility in module placement facilitates efficient system integration and management.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 900R4-0200 |

| Dimensions | 137 x 266.7 x 151.7 mm |

| Weight | 2.104 kg |

| Number of Slots | 4 |

| Input Voltage | 24 VDC ± 10% |

| Power Consumption | 15W |

| Operating Temperature | -40°C to +70°C |

| Mounting Type | Rack-mounted |

| Communication Protocol | Compatible with Honeywell PLCs |

| Connection Type | Modbus, Ethernet |

| Enclosure Rating | IP20 (Protection against dust and water splashing) |

Applications

The Honeywell 900R4-0200 4-Slot I/O Rack is used in a variety of industrial automation systems where modular I/O functionality is required. Some of its key applications include:

-

Distributed Control Systems (DCS): Used in DCS for real-time monitoring and control of industrial processes, providing critical I/O functionality.

-

Process Automation: Essential in process industries like chemical, oil & gas, and pharmaceuticals for seamless integration of input/output devices into automation systems.

-

Manufacturing and Assembly Lines: Facilitates control and automation in production environments, optimizing efficiency and accuracy in production processes.

-

Energy Management Systems: Ensures precise monitoring and control of energy consumption in large-scale industrial operations.

-

Water and Wastewater Treatment: Plays a vital role in controlling and monitoring systems in water treatment plants, ensuring reliable operation of pumps, sensors, and valves.

-

HVAC and Building Automation Systems: Used in smart building systems to integrate sensors, actuators, and controllers for efficient climate control and energy management.

Advantages

-

Modular Design: The 4-slot configuration allows for flexible expansion and easy reconfiguration of the I/O system, providing scalability as system requirements grow.

-

High-Performance Integration: Provides reliable and fast integration with Honeywell PLCs and other industrial automation systems, supporting advanced control and monitoring.

-

Compact and Efficient: The space-saving design ensures that the rack can be easily installed in a variety of environments without occupying too much space.

-

Robust and Durable: With an IP20 protection rating, the rack is designed to withstand harsh industrial environments while providing long-term, reliable operation.

-

Wide Operating Temperature Range: The module can operate effectively in a wide temperature range of -40°C to +70°C, ensuring reliable performance in diverse industrial settings.

-

Easy Installation: Rack-mounted design makes it straightforward to integrate into control panels and systems, facilitating quicker setup and deployment.

FAQ

-

What is the number of slots in the Honeywell 900R4-0200 rack?

The 900R4-0200 has 4 slots, allowing users to install up to four I/O modules. -

What type of voltage does the 900R4-0200 rack require?

The rack operates with a 24 VDC power supply, with a tolerance of ±10%. -

What communication protocols are supported by the 900R4-0200?

The rack is compatible with Modbus and Ethernet communication protocols for data transmission. -

What is the power consumption of the 900R4-0200 rack?

The 900R4-0200 has a power consumption of 15W. -

What is the protection rating of the 900R4-0200 rack?

The rack has an IP20 protection rating, offering protection against dust and splashing water. -

How many I/O modules can be installed in the 900R4-0200 rack?

The rack can house up to 4 I/O modules. -

What is the operating temperature range of the 900R4-0200 rack?

The module operates within a temperature range of -40°C to +70°C, making it suitable for various industrial environments. -

How is the 900R4-0200 rack mounted?

The rack is designed to be rack-mounted, making it easy to install in industrial control panels and automation systems. -

Is the 900R4-0200 rack compatible with all Honeywell PLCs?

Yes, the 900R4-0200 is designed to be fully compatible with Honeywell PLCs, ensuring seamless integration with Honeywell’s control systems. -

What is the weight of the 900R4-0200 I/O rack?

The weight of the 900R4-0200 is 2.104 kg.

Similar Models

| Model Number | Description |

|---|---|

| 900R4-0300 | 6-slot I/O rack for increased I/O capacity |

| 900R4-0400 | 8-slot I/O rack for large-scale industrial systems |

| 900R4-0100 | 2-slot I/O rack for compact control systems |

| 900R4-0500 | Rack with enhanced protection for harsh environments |

| 900R4-0600 | Modular I/O rack with advanced communication support |

| 900R4-0700 | High-performance 10-slot I/O rack for complex industrial setups |

Popular Honeywell Models

| Model Number | Description |

|---|---|

| 900C3-0210 | Advanced I/O module for Honeywell’s control systems |

| 900H4-0100 | Honeywell 4-slot I/O rack with high-speed communication support |

| 900R2-0210 | 2-slot I/O rack designed for compact automation systems |

| 900H3-0500 | High-density 10-slot I/O module for large-scale control systems |

| 900R1-0300 | Modular I/O rack with extended temperature range and high reliability |

| 900M1-0200 | 4-slot I/O rack designed for medium-sized industrial systems |

Excellent PLC

Excellent PLC