| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

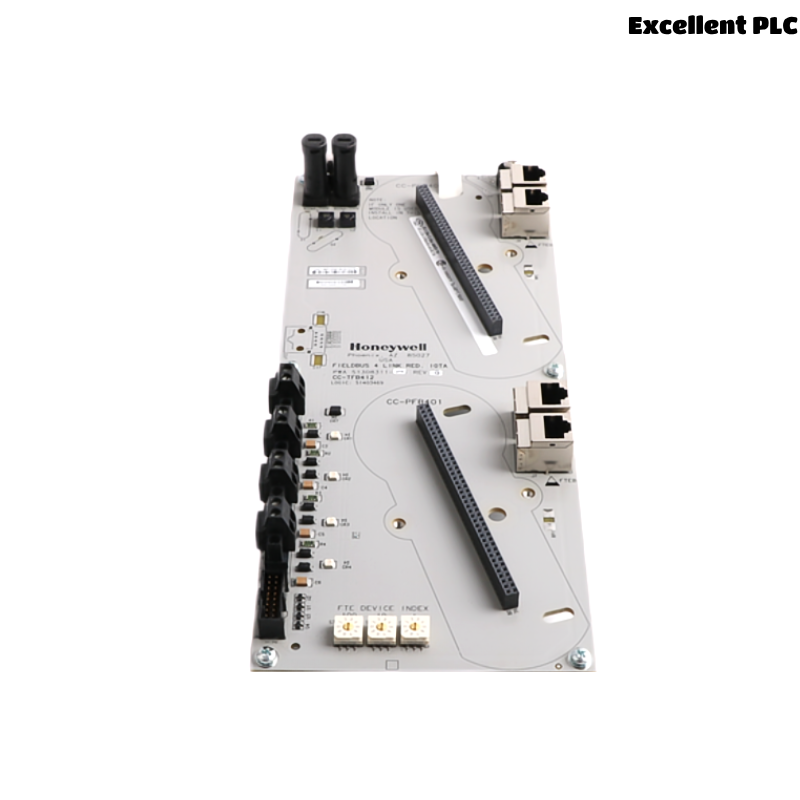

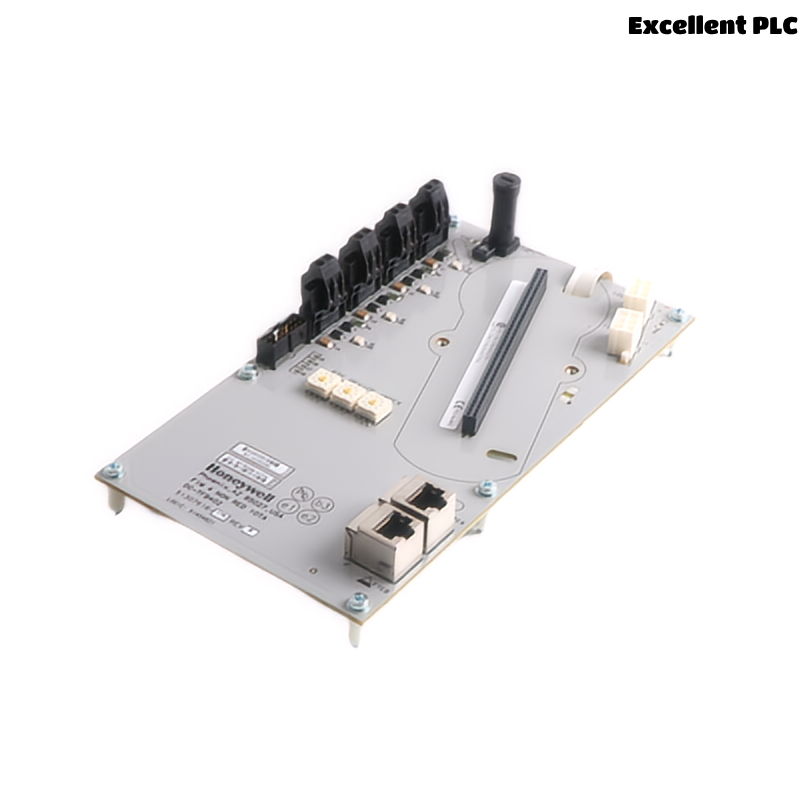

The Honeywell DC-TFB412 51307618-176 Fieldbus Interface IOTA Module is an advanced Foundation™ Fieldbus interface module, designed for seamless integration into Honeywell’s Series C I/O, Experion PKS, and C300 Controller systems.

As a next-generation IOTA (Input/Output Termination Assembly) module, the DC-TFB412 enables robust communication between the controller and connected Foundation™ Fieldbus H1 field devices. It provides a highly reliable, high-integrity physical interface, ensuring uninterrupted data exchange and consistent system performance in demanding industrial applications.

With its dual-channel architecture, advanced galvanic isolation, comprehensive diagnostics, and redundant power supply support, the DC-TFB412 is ideal for plants requiring modern digital fieldbus technology for process control, asset management, and real-time monitoring. The module is engineered to operate reliably in harsh environments, supporting long service life and superior control quality.

It is widely used in oil & gas, power generation, chemical processing, pulp & paper, water treatment, pharmaceuticals, and other process industries looking to implement high-speed, deterministic, and fault-tolerant fieldbus networks.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Honeywell DC-TFB412 Fieldbus Interface IOTA Module |

| Part Number | 51307618-176 |

| System Compatibility | Honeywell Experion PKS / C300 Controllers / Series C I/O |

| Interface Type | FOUNDATION™ Fieldbus |

| Supported Protocols | FOUNDATION™ Fieldbus H1 |

| Number of Channels | 2 Fieldbus H1 channels |

| Communication Speed | 31.25 kbit/s per channel |

| Galvanic Isolation | Yes — channel-to-logic and channel-to-channel |

| Diagnostics | Channel-level and module-level diagnostics |

| Status Indication LEDs | For channel status, fault, power |

| Power Supply | 24 VDC nominal (redundant supported) |

| Power Consumption | < 6 W typical |

| Operating Temperature Range | -20°C to +60°C (-4°F to +140°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Vibration / Shock Compliance | IEC 60068 compliant |

| Dimensions (H x W x D) | 120 x 90 x 55 mm |

| Weight | 0.8 kg |

| Mounting | DIN rail or panel mount |

| Flame Rating | UL 94V-0 |

| Certifications | CE, UL, CSA, ATEX Zone 2, IECEx |

Applications

-

Seamless integration with Foundation™ Fieldbus H1 devices

-

Smart field device communication for advanced process control

-

Distributed control in oil & gas upstream, refining, LNG

-

High-integrity process automation in chemical manufacturing

-

Power generation (thermal, nuclear, renewables)

-

Batch and continuous control in pharmaceutical plants

-

Fieldbus loop control in pulp & paper operations

-

Water and wastewater treatment plant automation

-

Hazardous area control — ATEX Zone 2 and IECEx certified

-

Food & beverage automation with real-time device feedback

Product Advantages

-

Dual FOUNDATION™ Fieldbus channels: Delivers two isolated H1 channels per module, maximizing integration density

-

Advanced isolation: Ensures galvanic isolation across channels and system logic for superior reliability

-

Redundant power support: Enables high system availability and fault tolerance

-

High-speed deterministic communication: Supports 31.25 kbit/s fieldbus rates for fast device interaction

-

Comprehensive diagnostics: Onboard LED indicators and system diagnostics simplify maintenance

-

Seamless Experion PKS integration: Fully compatible with Honeywell Experion PKS and C300 systems

-

Hazardous area certified: Designed for safe operation in ATEX Zone 2 and IECEx environments

-

Compact footprint: High-density form factor saves cabinet space and reduces installation costs

-

Flexible mounting: Can be DIN rail or panel mounted for ease of integration

-

Rugged, industrial-grade build: Designed to perform under vibration, temperature extremes, and electrical noise typical in process industries

Frequently Asked Questions (FAQ)

-

What is the DC-TFB412 module used for?

It is a dual-channel Foundation™ Fieldbus H1 interface module for Honeywell Experion PKS and C300 controllers. -

How many Fieldbus channels does it support?

The DC-TFB412 supports two Fieldbus H1 channels per module. -

What type of isolation does this module provide?

It provides full galvanic isolation between channels and between channels and system logic. -

Is it certified for use in hazardous areas?

Yes — it is ATEX Zone 2 and IECEx certified. -

What systems is this module compatible with?

It is compatible with Honeywell Experion PKS, Series C I/O, and C300 controllers. -

What is the data rate for each Fieldbus channel?

Each H1 channel communicates at 31.25 kbit/s. -

Does this module support redundant power inputs?

Yes — it supports redundant 24 VDC power supplies for high availability. -

Does it offer diagnostics?

Yes — channel-level and module-level diagnostics, with LED indicators, are built in. -

How is this module mounted?

It can be DIN rail mounted or panel mounted. -

What industries typically use the DC-TFB412?

Industries include oil & gas, power, chemicals, water treatment, pulp & paper, pharmaceuticals, and more.

Related Models (Same Series or Product Line)

| Model Number | Description |

|---|---|

| DC-TFB402 | Fieldbus Interface IOTA Module, dual-channel |

| DC-TFB401 | Fieldbus Interface IOTA Module, single-channel |

| DC-TAOX01 | Analog Output Module |

| DC-TAIX01 | Analog Input Module |

| DC-TDOD51 | Digital Output Module, Isolated, 16 channels |

| DC-TDIB01 | Digital Input Module, 16 channels |

Popular Honeywell Models (Same Brand)

| Model Number | Description |

|---|---|

| C300 Controller | Advanced Process Controller |

| HC900 Hybrid Controller | Hybrid Process and Safety Controller |

| FSC 10101 | High Integrity Safety Controller |

| RM7800 | Integrated Burner Management Control Module |

| UCN I/O Rack | Universal Control Network I/O Rack |

| S9000 PLC | Modular Safety PLC for industrial automation |

Excellent PLC

Excellent PLC