| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

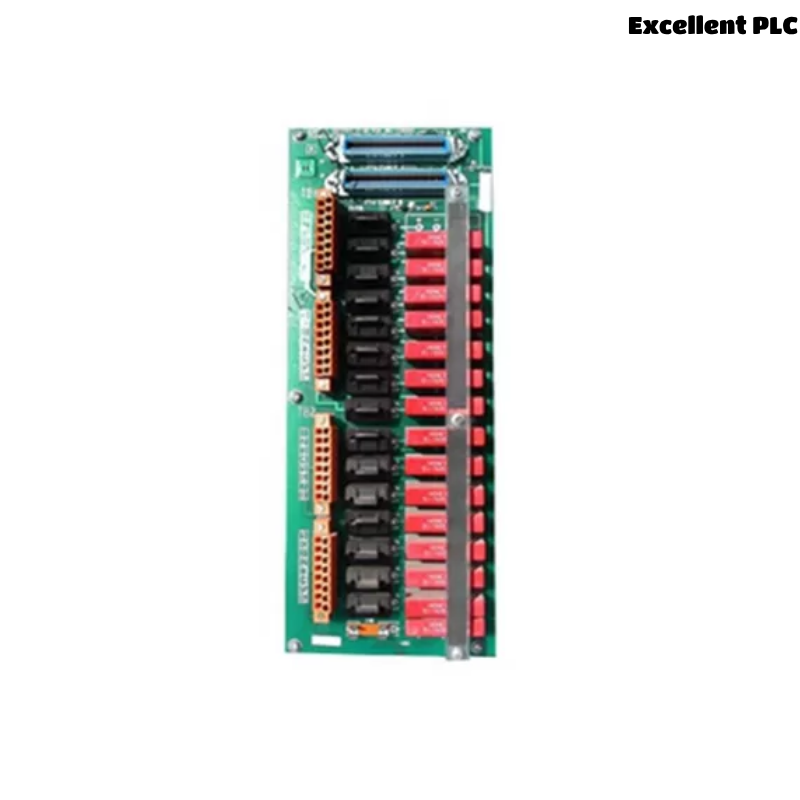

The Honeywell FS-PDB-IOX05 is a high-performance I/O expansion module designed for industrial automation and control systems. It provides seamless integration with Honeywell’s programmable logic controllers (PLCs) and distributed control systems (DCS), offering reliable signal conditioning and data acquisition capabilities. This module is widely used in process automation, manufacturing, and energy management applications due to its rugged design and high accuracy.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | FS-PDB-IOX05 |

| Input/Output Type | Digital/Analog I/O (Configurable) |

| Channels | 16 (8 Input / 8 Output) |

| Voltage Range | 24V DC (±10%) |

| Communication | Modbus RTU, Profibus DP |

| Operating Temp. | -20°C to +60°C |

| Humidity Range | 5% to 95% (Non-condensing) |

| Dimensions | 106 x 79 x 59 mm |

| Weight | 4.8 kg |

| Protection Rating | IP65 |

| Certifications | CE, UL, RoHS |

Product Applications

The Honeywell FS-PDB-IOX05 is suitable for a wide range of industrial applications, including:

-

Process Automation: Used in chemical plants, oil & gas refineries, and water treatment facilities for signal processing.

-

Manufacturing Systems: Integrates with assembly lines, robotic controls, and CNC machines.

-

Energy Management: Monitors power distribution and load balancing in smart grids.

-

Building Automation: Controls HVAC, lighting, and security systems in commercial buildings.

-

Transportation: Deployed in railway signaling and traffic management systems.

Product Advantages

-

Modular Design: Allows easy expansion and customization for different I/O requirements.

-

High Reliability: Built with industrial-grade components for long-term durability.

-

Wide Compatibility: Supports multiple communication protocols (Modbus, Profibus).

-

Easy Installation: Compact size and DIN-rail mounting for quick setup.

-

Robust Protection: IP65 rating ensures resistance to dust and moisture.

-

Low Maintenance: Self-diagnostic features reduce downtime.

Frequently Asked Questions (FAQ)

Q1: What is the maximum current rating per channel?

A1: Each channel supports up to 2A for digital outputs and 10mA for analog inputs.

Q2: Can this module be used in hazardous environments?

A2: No, it is not certified for hazardous areas (ATEX/IECEx).

Q3: Is the FS-PDB-IOX05 compatible with Honeywell’s Experion PKS?

A3: Yes, it can be integrated via Modbus RTU.

Q4: What is the response time for digital inputs?

A4: Typically <5ms.

Q5: Does it support hot-swapping?

A5: No, power must be disconnected before module replacement.

Q6: How many modules can be daisy-chained?

A6: Up to 32 modules on a single Profibus DP network.

Q7: What software is needed for configuration?

A7: Honeywell’s ControlEdge or third-party Modbus tools.

Q8: Are the analog inputs isolated?

A8: Yes, they have 1500V optical isolation.

Q9: Can it operate in high-vibration environments?

A9: Yes, it withstands vibrations up to 5g.

Q10: How long is the warranty period?

A10: The standard warranty is 1 years, subject to proper usage and conditions.

Recommended Models

Same Series / Related Models

| Model | Description | Key Difference |

|---|---|---|

| FS-PDB-IOX10 | 32-Channel I/O Module | Higher channel count |

| FS-PDB-AIX04 | Analog Input Module (16ch) | Dedicated analog inputs |

| FS-PDB-DOX08 | Digital Output Module (8ch) | Relay outputs |

| FS-PDB-COM02 | Communication Gateway (Ethernet/IP) | Enhanced networking |

| FS-PDB-PWR12 | Power Supply Unit (24V/10A) | For multi-module setups |

| FS-PDB-ENET01 | Ethernet I/O Expander | LAN connectivity |

Popular Honeywell Models

| Model | Category | Application |

|---|---|---|

| HC900 | Process Controller | Small-scale automation |

| TDC3000 | DCS System | Large industrial plants |

| XYR 5000 | Wireless Transmitter | Remote monitoring |

| ST3000 | Pressure Transmitter | Oil & gas pipelines |

| MCS | Safety System | Emergency shutdowns |

| Experion PKS | SCADA Platform | Plant-wide control |

Excellent PLC

Excellent PLC