| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

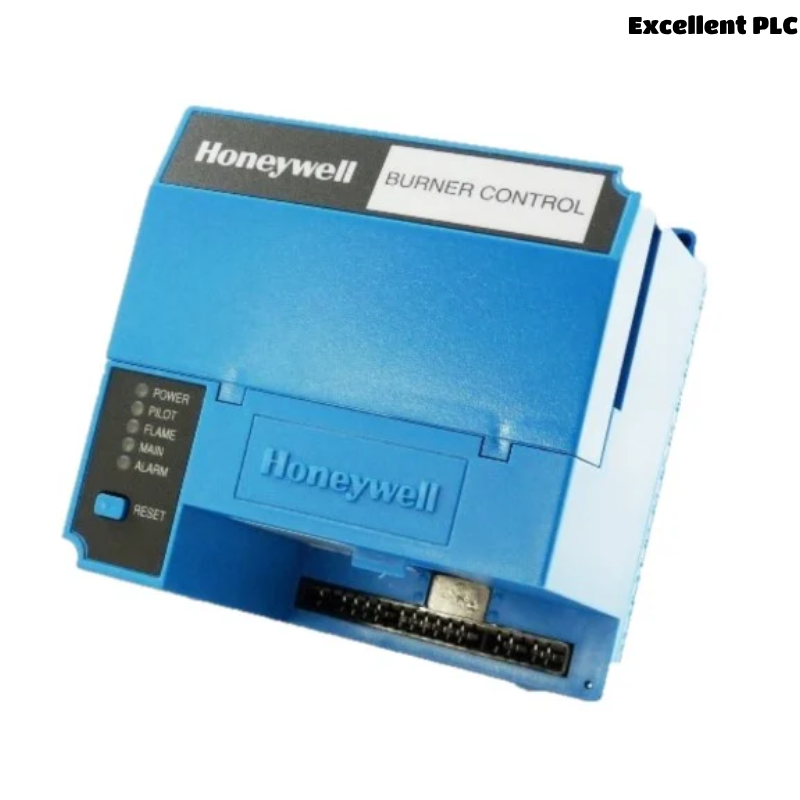

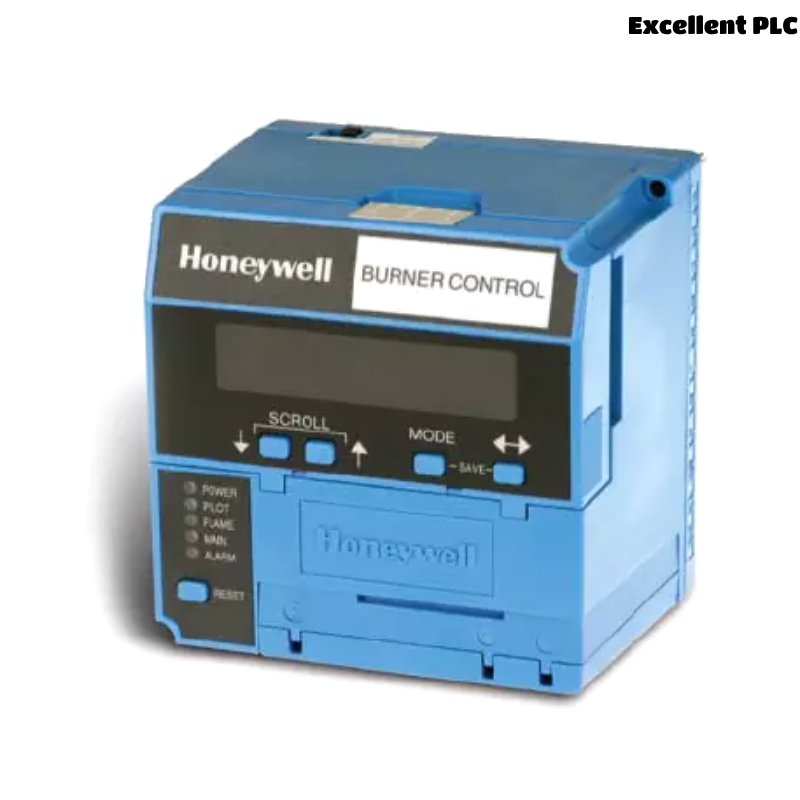

The Honeywell RM7800G1018 is an advanced, microprocessor-based integrated burner control designed for use in commercial and industrial heating applications. Part of Honeywell’s renowned RM7800 series, this model offers reliable flame safeguard, system sequencing, and safety monitoring for burners, boilers, and related combustion equipment. Built to replace obsolete electromechanical controls, the RM7800G1018 ensures high operational safety, precise timing, and enhanced diagnostics. Its modular design and wide compatibility make it an essential component for modern burner management systems.

Technical Specifications

| Item | Specification |

|---|---|

| Model | RM7800G1018 |

| Control Type | Primary burner control |

| Supply Voltage | 120 Vac, 50/60 Hz |

| Operating Temperature | -40°F to +140°F (-40°C to +60°C) |

| Humidity Range | 0% to 85% RH (non-condensing) |

| Dimensions | 127 x 127 x 110 mm |

| Weight | 0.68 kg |

| Enclosure | Flame-retardant plastic housing |

| Display | LED diagnostic indicators |

| Flame Detection Type | Compatible with rectification, UV, and infrared amplifiers |

| Sequence Options | Programmable with compatible keyboards and displays |

| Safety Shutoff Control | Integrated, with lockout and manual reset |

Product Applications

The Honeywell RM7800G1018 is widely applied in:

-

Industrial boilers and steam generators

-

Commercial hot water and heating boilers

-

Process heaters and ovens

-

Air heaters and thermal oil heaters

-

Incinerators and large gas burners

-

Applications requiring integrated flame safeguard and burner sequencing

Its versatility makes it suitable for new systems or as a retrofit in upgrading older mechanical or analog flame safeguard systems.

Product Advantages

-

Enhanced Safety: Continuous self-checking circuitry and fail-safe design reduce risks of burner misfire and hazardous conditions.

-

Diagnostic Capability: Built-in LEDs and optional display modules provide real-time fault and operating status information.

-

Flexible Integration: Compatible with multiple flame detection options (UV, rectification, IR) and suitable for gas, oil, or combination burners.

-

Proven Reliability: Industrial-grade design ensures stable operation in harsh environments, including wide temperature and humidity ranges.

-

User-Friendly Maintenance: Modular plug-in components and standardized wiring simplify installation and reduce service time.

-

Long Service Life: Rugged housing and solid-state electronics contribute to a long operational lifespan with minimal downtime.

Frequently Asked Questions (FAQ)

Q1: What type of flame detectors are supported?

A1: It supports ultraviolet, infrared, and rectification flame detectors when used with compatible Honeywell flame amplifiers.

Q2: Is the RM7800G1018 compatible with both oil and gas burners?

A2: Yes, it is suitable for gas, oil, or dual-fuel applications, as long as proper detectors and amplifiers are used.

Q3: How does the lockout function work?

A3: Upon detecting unsafe conditions, the unit enters lockout mode, stopping burner operation until a manual reset is performed.

Q4: Can I monitor faults remotely?

A4: Yes, through optional display modules like the S7800A1142 or via building automation system integration.

Q5: What are the main differences compared to older RM7000 series controls?

A5: The RM7800G1018 offers advanced diagnostics, modular design, broader flame detection compatibility, and improved reliability.

Q6: How do I reset the control after lockout?

A6: Reset is typically done by pressing the external reset button or through an optional remote reset module.

Q7: Does it need periodic calibration?

A7: No periodic calibration is needed; only regular operational checks and detector maintenance are recommended.

Q8: Is this control UL approved?

A8: Yes, it meets UL safety standards for flame safeguard devices.

Q9: Can it operate outdoors?

A9: It must be installed in a dry, protected enclosure to prevent moisture and direct sunlight exposure.

Q10: What is the typical service life of the RM7800G1018?

A10: When properly installed and maintained, it often lasts over 5 years.

Recommended 6 Same Series or Related Models

-

RM7800L1075 – Primary burner control with extended functions

-

RM7800M1018 – Integrated primary control with multi-burner sequencing

-

RM7800E1012 – Control with expanded diagnostic capability

-

RM7800D1004 – Basic burner control with lockout and safety monitoring

-

RM7840G1018 – Specialized burner control with multiple flame amplifier options

-

RM7823A1017 – Standard primary control for light commercial applications

6 Other Popular Honeywell Models (with specs)

| Model | Voltage | Dimensions (inches) | Weight | Application Area |

|---|---|---|---|---|

| RM7840L1075 | 120 Vac | 5.0 x 5.0 x 6.0 | 3 lbs | Industrial burners, multi-fuel |

| RM7823A1017 | 120 Vac | 5.0 x 5.0 x 6.0 | 3 lbs | Light commercial boilers |

| R7861A1024 | 120 Vac | 4.5 x 3.0 x 2.0 | 1 lb | Flame amplifier for rectification |

| R7849A1023 | 120 Vac | 4.0 x 2.5 x 2.0 | 0.8 lb | UV flame amplifier |

| R7851B1030 | 120 Vac | 4.0 x 2.5 x 2.0 | 0.8 lb | IR flame amplifier |

| S7800A1142 | 24 Vac | 4.5 x 3.5 x 1.8 | 0.5 lb | Display and communication module |

Excellent PLC

Excellent PLC