| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

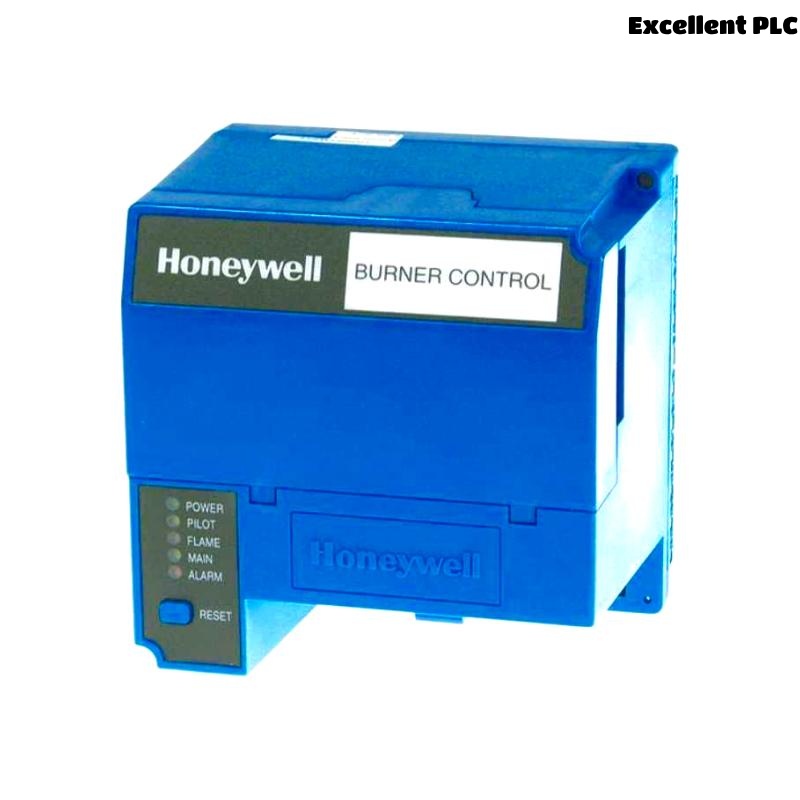

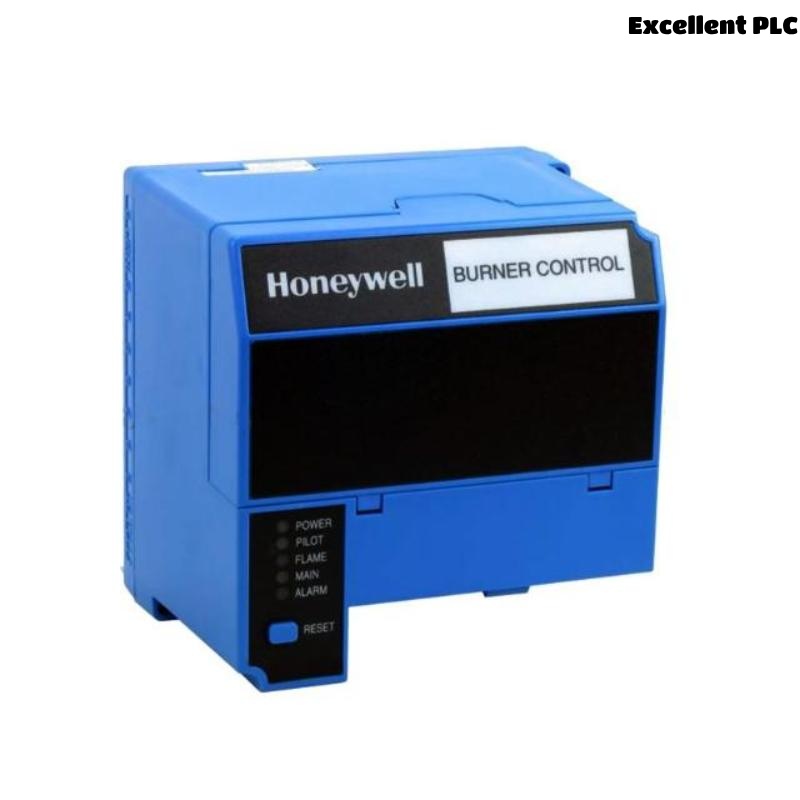

Honeywell RM7890B1014 Industrial Pressure Transmitter

Product Introduction

The Honeywell RM7890B1014 is a rugged, high-accuracy pressure transmitter designed for critical industrial process applications. Engineered with military-grade components, this transmitter provides reliable performance in oil/gas, chemical processing, and power generation environments where measurement stability under extreme conditions is paramount.

Technical Specifications

| Category | Specification |

|---|---|

| Model Identifier | RM7890B1014 |

| Product Line | Honeywell Precision Industrial Sensors |

| Measurement Type | Gauge/Absolute/Differential Pressure (configurable) |

| Pressure Range | 0-100 psi to 0-10,000 psi (field-selectable ranges) |

| Output Signal | 4-20mA HART® w/ superimposed digital signal |

| Accuracy | ±0.075% of calibrated span (best-in-class) |

| Long-Term Stability | ±0.1% URL/year |

| Process Connection | 1/2″ NPT male / DIN 3852-E / Custom flanges available |

| Electrical Connection | 1/2″ NPT conduit entry / M12x1 threaded connector |

| Housing Material | 316L stainless steel with Hastelloy® C276 isolation diaphragms |

| Display | 4-digit LCD with 360° rotation (local indication optional) |

| Dimensions | 127 × 127 × 152 mm |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to 125°C (-40°F to 257°F) |

| Storage Temperature | -50°C to 150°C (-58°F to 302°F) |

| Ingress Protection | IP68 / NEMA 6P (submersible to 3m for 72hrs) |

| Certifications | ATEX, IECEx, SIL 2, CE, RoHS, CRN |

| Warranty | 1-year limited warranty |

Typical Applications

Oil & Gas

-

Wellhead pressure monitoring

-

Pipeline leak detection systems

-

Refinery process control

Power Generation

-

Boiler steam pressure measurement

-

Turbine inlet/outlet monitoring

Chemical Processing

-

Reactor vessel overpressure protection

-

Corrosive fluid handling systems

Water/Wastewater

-

Pump discharge pressure control

-

Deep well monitoring

HVAC

-

Chilled water system optimization

-

Critical environment pressure differentials

Competitive Advantages

-

Military-Grade Durability

-

Vibration resistant to 20g @ 200Hz

-

Survives hydraulic shock pulses up to 100MPa

-

-

Smart Diagnostics

-

Built-in sensor health monitoring

-

Predictive maintenance alerts via HART®

-

-

Zero Drift Technology

-

Patented ASIC compensation eliminates thermal drift

-

-

Installation Flexibility

-

100:1 turndown ratio reduces inventory needs

-

Field-replaceable electronics module

-

-

Lifecycle Cost Reduction

-

10-year mean time between failures (MTBF)

-

No required recalibration for 60 months

-

Frequently Asked Questions

Q1: What is the maximum proof pressure?

A1: 1.5x URL (Upper Range Limit) without permanent damage.

Q2: Can it measure viscous media like crude oil?

A2: Yes, with optional flush diaphragm configurations.

Q3: Is explosion-proof certification available?

A3: ATEX II 1G Ex ia IIC T6 Ga certified.

Q4: What power supply is required?

A4: 10.5-42V DC loop powered (2-wire configuration).

Q5: How is damping adjusted?

A5: Software configurable from 0-32 seconds via HART® communicator.

Q6: What is the wetted materials list?

A6: 316L SS, Hastelloy C276, Kalrez® seals (standard).

Q7: Can it interface with PLC systems?

A7: Yes, supports Modbus RTU over HART® and native Profibus PA versions.

Q8: What is the step response time?

A8: <5ms for 90% step change (fastest in class).

Q9: Are special calibration fluids needed?

A9: No – factory calibrated with NIST-traceable nitrogen.

Q10: How are firmware updates performed?

A10: Field-upgradable via HART® DD files or Honeywell FieldCare® software.

Recommended Alternative Models

Same Product Family

| Part Number | Key Differentiation | Best For |

|---|---|---|

| RM7890B1015 | 0-30,000 psi ultra-high range | Downhole drilling |

| RM7890B1016 | Sanitary Tri-Clamp connection | Pharma/biotech |

| RM7890B1017 | Intrinsically safe (Class I Div 1) | Petrochemical plants |

| RM7890B1018 | Subsea version to 3000m depth | Offshore platforms |

| RM7890B1019 | WirelessHART® enabled | Remote monitoring |

| RM7890B1020 | ±0.04% accuracy laboratory grade | Custody transfer |

Complementary Honeywell Products

| Part Number | Product Type | Synergy Benefit |

|---|---|---|

| ST3000™ Series | Multivariable transmitter | Adds flow/temp measurement |

| HC900 Controller | Process control unit | Closed-loop system integration |

| XSeries™ Switches | Pressure safety devices | Overpressure protection |

| Tridium® N4 | Building automation platform | Facility-wide monitoring |

| Experion® PKS | SCADA system | Enterprise-level data aggregation |

| OneWireless™ | Network infrastructure | Wireless sensor mesh networks |

Excellent PLC

Excellent PLC