| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

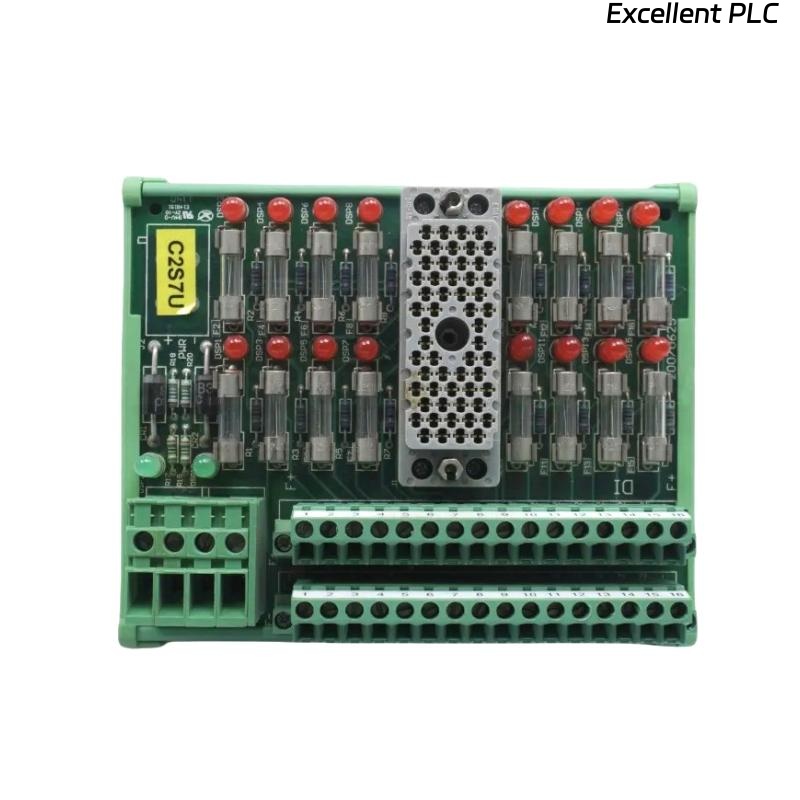

The Invensys Triconex 3007 is a critical component in the Triconex safety system family, designed to provide reliable input and control for industrial processes where safety is a top priority. It is a Main Processor Module that is part of the Tricon controller family, which is known for offering high availability and fault tolerance for safety instrumented systems (SIS). The Triconex 3007 is specifically engineered to enhance safety in process control, enabling continuous monitoring and protection of critical processes across a wide range of industrial sectors, including oil & gas, power generation, chemical, and manufacturing industries.

This module works seamlessly within a Triconex safety architecture to ensure safety-critical functions, such as emergency shutdown (ESD) systems and process protection, continue to operate even in the event of a fault. It is well-suited for hazardous environments, ensuring that operations remain safe and reliable even in extreme conditions.

Product Specifications

| Specification | Details |

|---|---|

| Product Type | Main Processor Module |

| Model Number | Triconex 3007 |

| Channels | 7 |

| Input Type | Digital Input (Dry Contact) |

| Voltage Range | 24 V DC |

| Current Consumption | 50 mA (per channel) |

| Temperature Range | -20°C to +60°C |

| Dimensions (H x W x D) | 228 x 160 x 75 mm |

| Weight | 1.5 kg |

| Mounting | DIN Rail |

| Certification | UL, CE, Ex (ATEX), CSA |

| Response Time | < 10 ms per channel |

| Isolation | Galvanic Isolation |

| LED Indicators | Yes (Status, Error) |

Applications

The Invensys Triconex 3007 is commonly deployed in industries that require high safety standards and fault tolerance. Its key applications include:

- Oil and Gas: Used in safety instrumented systems to protect critical infrastructure, ensuring safe shutdowns and monitoring of hazardous processes.

- Power Generation: Plays an essential role in turbine protection, emergency shutdown, and process control systems to ensure the safe operation of power plants.

- Chemical Processing: Provides critical input for monitoring temperature, pressure, and flow, helping to safeguard against chemical hazards and ensuring plant safety.

- Manufacturing: In industries such as automotive and food processing, the module ensures that automated systems operate safely, reducing downtime and preventing accidents.

- Pharmaceuticals: Ensures the continuous and safe operation of automated systems involved in drug manufacturing and packaging, which are highly regulated for safety.

Advantages

- High Fault Tolerance: With 7 digital input channels, the Triconex 3007 ensures that processes remain operational even in the event of individual component failures.

- Safety Compliance: The module complies with industry safety standards, including UL, CE, and ATEX certifications, making it suitable for hazardous environments.

- Redundant Design: The design of the module ensures redundancy, offering continuous operation even when a failure occurs.

- Real-Time Response: With a response time of less than 10 ms, the Triconex 3007 provides quick feedback on input changes, ensuring that safety systems are activated instantly.

- Compact Design: Despite its robust capabilities, the module features a compact design that allows easy installation in space-constrained environments.

- Ease of Maintenance: The module supports hot-swapping, meaning it can be replaced without shutting down the entire system, minimizing downtime.

- Improved Process Integrity: The Triconex 3007 helps to maintain the integrity of critical processes by providing reliable input monitoring and safe control.

Latest News Titles

- “Invensys Triconex 3007 Digital Input Module Enhances Safety in Oil & Gas Operations”

- “Triconex 3007: Leading the Way in Critical Process Safety Monitoring”

- “Invensys Triconex Announces New Safety Input Modules to Improve Plant Reliability”

- “How Triconex 3007 Reduces Downtime in Hazardous Industries”

- “Invensys Triconex Expands Product Line with New 7-Channel Input Module”

- “Triconex 3007 Revolutionizes Safety Instrumented Systems for Chemical Plants”

- “High Availability and Redundancy with Triconex 3007: A Game-Changer for Power Plants”

- “Ensuring Worker Safety with Triconex 3007 Digital Input Module in Manufacturing Plants”

- “Invensys Triconex 3007 Offers Robust Performance for Critical Pharmaceutical Applications”

- “The Impact of Triconex 3007 on Process Control Safety in Highly Regulated Industries”

Frequently Asked Questions (FAQ)

-

What is the Triconex 3007 used for?

- The Triconex 3007 is a Main Processor Module used in safety instrumented systems to provide reliable monitoring and control in critical processes.

-

How many channels does the Triconex 3007 support?

- The Triconex 3007 has 7 input channels.

-

What type of inputs does the Triconex 3007 handle?

- It handles digital inputs, typically from dry contact sensors.

-

What voltage does the Triconex 3007 operate on?

- The Triconex 3007 operates on a 24 V DC voltage range.

-

What is the weight of the Triconex 3007?

- The module weighs 1.5 kg.

-

Can the Triconex 3007 be used in hazardous environments?

- Yes, it has ATEX, UL, and CE certifications, making it suitable for use in hazardous environments.

-

What is the response time of the Triconex 3007?

- The response time for each channel is less than 10 ms.

-

What are the dimensions of the Triconex 3007 module?

- The module’s dimensions are 228 x 160 x 75 mm.

-

Can the Triconex 3007 be easily installed?

- Yes, the module is designed for DIN rail mounting, making installation easy.

-

Does the Triconex 3007 support hot swapping?

- Yes, it supports hot swapping, which allows you to replace the module without shutting down the system.

Recommended Related Models

| Model Number | Description | Specifications |

|---|---|---|

| Triconex 3006 | 6-channel digital input module | 24 V DC, Galvanic Isolation, 6 Inputs |

| Triconex 3005 | 5-channel digital input module | 24 V DC, High-speed Response, 5 Inputs |

| Triconex 3008 | 8-channel digital input module | 24 V DC, Compact Design, 8 Inputs |

| Triconex 3010 | 10-channel digital input module | 24 V DC, ATEX Certified, 10 Inputs |

| Triconex 3011 | 16-channel digital input module | 24 V DC, High-speed, 16 Inputs |

| Triconex 3009 | 9-channel digital input module | 24 V DC, Redundant Design, 9 Inputs |

| Triconex 3012 | 12-channel digital input module | 24 V DC, Versatile, 12 Inputs |

| Triconex 3020 | 20-channel digital input module | 24 V DC, Multi-purpose, 20 Inputs |

| Triconex 3030 | 30-channel digital input module | 24 V DC, Heavy-duty, 30 Inputs |

| Triconex 3004 | 4-channel digital input module | 24 V DC, Compact, 4 Inputs |

Popular Invensys Models

| Model Number | Description | Specifications |

|---|---|---|

| Triconex 3501 | High-performance safety module for emergency shutdowns | 24 V DC, Redundant Design, 4 Outputs |

| Triconex 3510 | Comprehensive SIS system with I/O integration | 24 V DC, Advanced Features, 8 Channels |

| Triconex 3502 | Safety-critical controller for power plants | 24 V DC, 16 Channels, Compact Design |

| Triconex 3504 | Distributed control for hazardous applications | 24 V DC, 12 Channels, Fault-Tolerant |

| Triconex 3506 | Digital output module for process control | 24 V DC, 6 Outputs, High Reliability |

| Triconex 3508 | Analog input/output module for power stations | 0-10 V, 4-20 mA, 8 Inputs/Outputs |

| Triconex 3512 | Integrated input/output for chemical processes | 24 V DC, 12 Inputs/Outputs, Galvanic Isolation |

| Triconex 3503 | Multi-channel safety module for critical systems | 24 V DC, 10 Inputs/Outputs, Compact |

| Triconex 3515 | Safety monitoring system for turbines and compressors | 24 V DC, Redundant, 16 Channels |

| Triconex 3516 | Integrated safety control system | 24 V DC, 8 Inputs, 8 Outputs |

Excellent PLC

Excellent PLC