| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

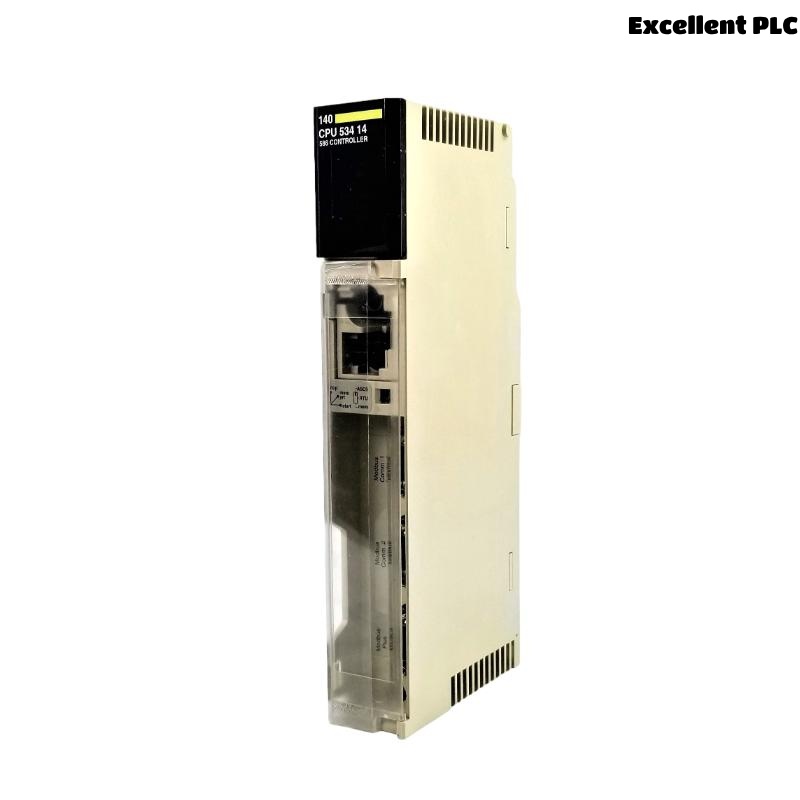

The Schneider Electric 140CPU53414C is a robust and versatile CPU module from the well-established Modicon Quantum series, designed to manage sophisticated automation processes in large-scale industrial environments. Known for its high reliability, processing performance, and modular compatibility, this controller is widely used in industries where consistent uptime, data accuracy, and real-time control are critical.

Equipped with Modbus and Ethernet communication ports and programmed through the EcoStruxure Control Expert (formerly Unity Pro) platform, the 140CPU53414C delivers seamless integration, advanced logic processing, and support for complex industrial protocols. This model is built for flexibility—capable of supporting both new deployments and legacy system upgrades within Quantum infrastructure.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 140CPU53414C |

| Product Line | Modicon Quantum |

| Processor Type | 32-bit processor, 66 MHz |

| Application Memory | 1 MB |

| Internal RAM | 4 MB |

| Programming Software | Unity Pro / EcoStruxure Control Expert |

| Communication Ports | 1 × Ethernet RJ45, 1 × Modbus, 1 × RS-232/RS-485 |

| Protocols Supported | Modbus, Modbus TCP/IP, Ethernet/IP |

| Hot Standby Support | Yes |

| Expandable Memory | Yes (via PCMCIA memory card) |

| Power Supply Requirement | 5 V DC via Quantum backplane |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions (H × W × D) | 103.9 × 40.3 × 250 mm |

| Weight | 0.522 kg |

| Certifications | CE, UL, CSA, RoHS, ATEX |

Applications

The 140CPU53414C is ideal for a wide range of industrial control systems requiring precision, scalability, and long-term reliability:

-

Water and Wastewater Management

Controls treatment processes, pump stations, and remote terminal units within municipal networks. -

Power Generation and Energy Distribution

Used in SCADA-controlled substations, power plants, and renewable energy installations for distributed control and automation. -

Oil & Gas Production

Handles refining, upstream drilling automation, compressor control, and pipeline monitoring with support for redundant setups. -

Manufacturing and Assembly Lines

Facilitates motion control, material handling, robotics integration, and high-speed discrete manufacturing. -

Pharmaceutical and Food Processing

Manages temperature, batch consistency, clean-in-place (CIP) processes, and regulatory compliance workflows. -

Infrastructure and Transportation

Controls HVAC, lighting, conveyor belts, and tunnel ventilation in metro stations, airports, and smart buildings.

Advantages

-

Unified Software Environment

Easily programmed using EcoStruxure Control Expert, offering standardized IEC 61131-3 languages, diagnostics, and simulation tools. -

Flexible Communication Options

Integrated support for Modbus, Ethernet/IP, and TCP/IP ensures fast and reliable networking with upstream systems and field devices. -

High Performance with Redundancy

Supports hot standby CPU configurations, ensuring minimal downtime and fault recovery for mission-critical applications. -

Memory Expandability

With 1 MB of application memory and PCMCIA card support, the system is scalable and future-proof for program growth. -

Compatibility with Quantum Architecture

Seamlessly integrates into Quantum racks and power supplies, reducing engineering time and retrofitting effort. -

Certified for Harsh Environments

ATEX, UL, and CE certified for demanding and regulated industrial settings.

Frequently Asked Questions (FAQ)

1. What programming environment is used for the 140CPU53414C?

This CPU is programmed using Unity Pro, now known as EcoStruxure Control Expert, Schneider Electric’s comprehensive PLC software platform.

2. Is it possible to set up hot standby redundancy with this CPU?

Yes, the 140CPU53414C supports hot standby redundancy, allowing uninterrupted operation in critical applications.

3. Does the module support memory expansion?

Yes, it supports PCMCIA memory cards for storing large or backup applications.

4. Which industrial protocols does it support out of the box?

The CPU supports Modbus RTU, Modbus TCP/IP, and Ethernet/IP, offering wide integration capabilities.

5. Can this controller integrate with SCADA and HMI systems?

Yes, it integrates smoothly with SCADA and HMI platforms using its communication ports and standard industrial protocols.

6. Is this CPU compatible with older Quantum I/O modules?

Absolutely. It is fully backward-compatible with existing Quantum racks, I/O modules, and power supplies.

7. Can firmware updates be managed remotely?

Yes, firmware and application updates can be deployed via Ethernet using Schneider’s software tools.

8. Is it suitable for regulated industrial environments?

Yes, with certifications including ATEX, UL, and CSA, it is designed for use in hazardous and controlled industrial spaces.

9. How does the controller handle real-time data processing?

Its 66 MHz processor and structured memory architecture ensure fast and deterministic data processing for time-sensitive applications.

10. Can the module be used in distributed control systems?

Yes, it’s ideal for distributed architectures, allowing remote I/O and multi-controller systems through its networking capabilities.

Related Models from the Same Series

| Model | Description | Key Feature |

|---|---|---|

| 140CPU53414B | Standard Quantum CPU | Unity-compatible, high-speed logic |

| 140CPU53414AC | Quantum CPU with application redundancy | Supports Unity, redundant-ready |

| 140CPU65160 | High-end Quantum CPU | 2 MB memory, faster execution |

| 140CPU67261 | Advanced CPU with networking focus | Supports 10/100 Ethernet, enhanced memory |

| 140CPU43412AC | Mid-range CPU for general automation | Compact and cost-effective |

| 140CPU31110 | Entry-level CPU module | Basic applications, low resource use |

Popular Schneider Electric Models

| Model | Description | Typical Use |

|---|---|---|

| Modicon M580 | Ethernet-based PAC with cybersecurity features | IIoT, critical manufacturing systems |

| Modicon M340 | Compact PLC for mid-sized systems | Discrete, batch, and motion control |

| Altivar Process ATV600 | Variable speed drive for energy optimization | Pumps, HVAC, compressors |

| Lexium 32 Servo Drive | Precision servo system for motion control | Robotics, CNC, high-speed packaging |

| Magelis GTO HMIs | High-performance operator interface | SCADA/HMI integration, machine interface |

| Zelio Logic Smart Relay | Compact logic relay for small control applications | HVAC, lighting, basic automation tasks |

Excellent PLC

Excellent PLC