| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

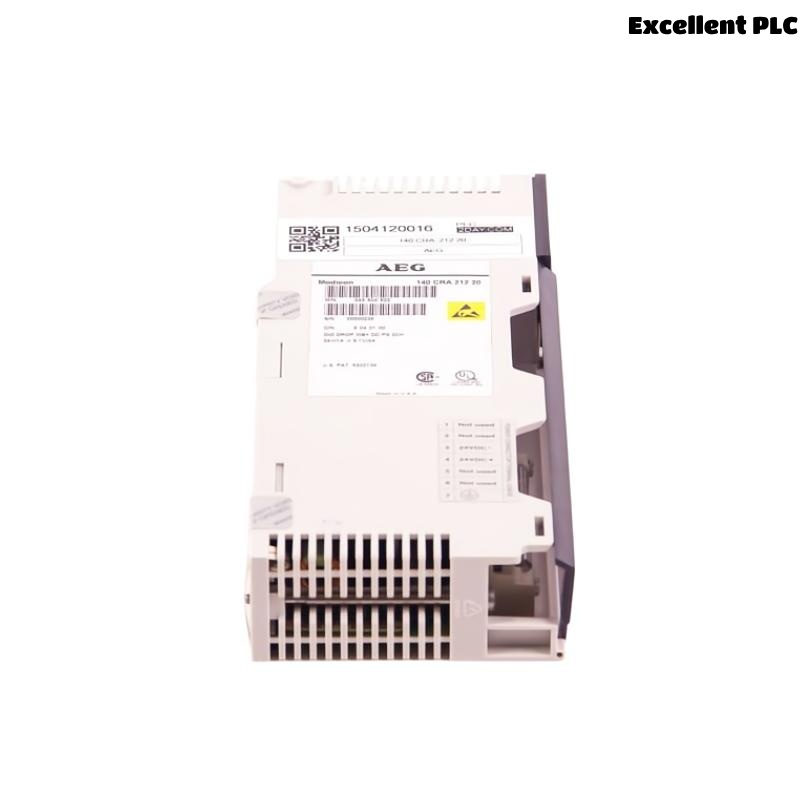

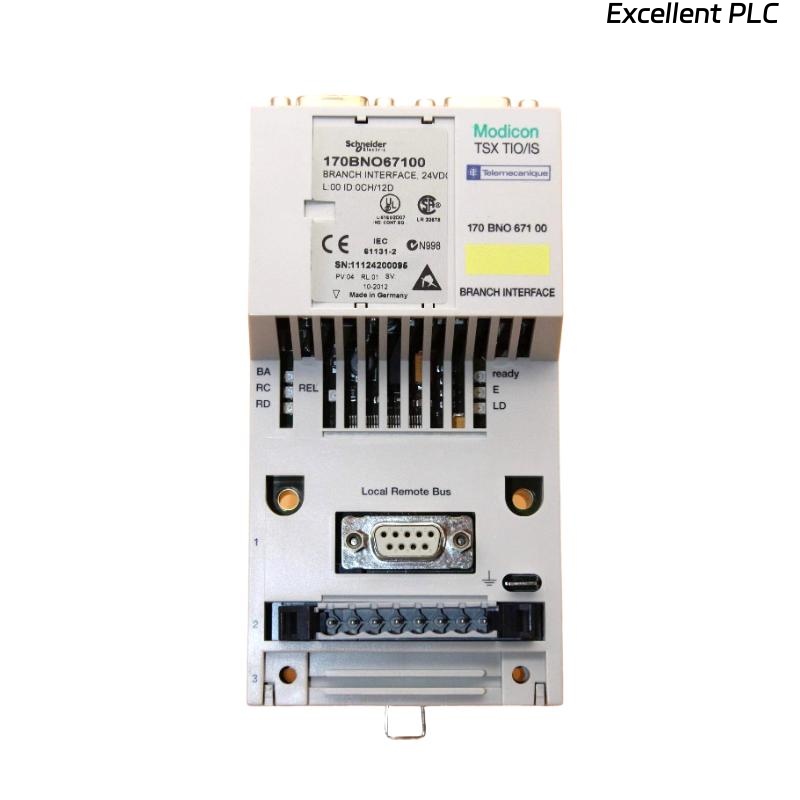

The Schneider Electric 140CRA21220C is a Distributed I/O (DIO) Drop Interface Module designed for use with the Modicon Quantum automation platform. Operating over the S908 Remote I/O (RIO) network, this module serves as a critical communication interface that links a central Quantum CPU to distributed remote I/O devices.

Designed for high-performance and reliability, the 140CRA21220C facilitates decentralized control architectures where I/O modules can be physically separated from the CPU but function seamlessly as part of the same system. This makes it particularly well-suited for large-scale industrial operations, such as chemical processing, energy generation, water utilities, and infrastructure control systems.

Compact and robust, this module supports fast and efficient communication, ease of integration with Schneider’s Unity Pro (now EcoStruxure Control Expert), and long-term stability under demanding environmental conditions.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 140CRA21220C |

| Product Type | DIO Drop Interface Module |

| Product Series | Modicon Quantum |

| Communication Protocol | S908 Remote I/O (RIO) |

| Interface Role | Connects CPU to remote I/O rack |

| Network Medium | Coaxial Cable with BNC 75 Ohm termination |

| Communication Speed | Up to 1.5 Mbps |

| Number of Supported Drops | 1 per module |

| Status Indicators | Module status, I/O activity, communication status (LEDs) |

| Software Compatibility | Unity Pro / EcoStruxure Control Expert |

| Installation | Installed in a Quantum rack backplane slot |

| Power Supply | 5 V DC provided via backplane |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, RoHS, ATEX |

| Package Size | 50 ×160 ×315 mm |

| Package Weight | 0.724 kg |

Product Applications

The 140CRA21220C plays a vital role in remote automation setups by allowing remote input/output (I/O) stations to interface seamlessly with a central controller. This modular design is especially beneficial in environments that require:

-

Remote Monitoring and Control

Plants where equipment is distributed across long distances, such as in refineries, chemical processing plants, or water treatment facilities. -

Power Generation Facilities

Linking auxiliary control equipment (e.g., turbine controls, switchgear panels) to central PLCs for coordinated operation. -

Oil and Gas Operations

Ideal for remote wellhead monitoring, offshore rig automation, and compressor stations. -

Automated Manufacturing

Used in large assembly lines and robotic cells where I/O modules are separated across production zones. -

Food and Beverage Industry

Connecting distributed conveyors, sensors, and filling machines for centralized control and monitoring. -

Transportation and Infrastructure

Deployed in tunnel control systems, ventilation monitoring, and smart building automation.

Key Advantages

-

Remote Connectivity

Allows I/O modules to be located close to field devices, significantly reducing wiring cost and complexity. -

High-Speed Communication

S908 RIO protocol supports real-time data transfer up to 1.5 Mbps, ensuring fast and synchronized operations. -

Reliable Industrial Design

Built to operate in harsh environments, with wide temperature tolerance and high vibration resistance. -

Ease of Integration

Compatible with Schneider’s Unity Pro / EcoStruxure Control Expert for seamless software configuration. -

Diagnostics & Status Feedback

LED indicators and software diagnostics simplify maintenance and troubleshooting. -

Compact Form Factor

Small footprint allows installation in space-constrained panels without sacrificing performance. -

Scalability

Facilitates easy system expansion by allowing additional remote I/O stations as needed.

Frequently Asked Questions (FAQ)

1. What is the function of the 140CRA21220C module?

It connects a Modicon Quantum CPU to a remote I/O drop via the S908 network.

2. Is the module compatible with all Quantum CPUs?

Yes, any Quantum CPU that supports RIO/S908 communication can interface with this module.

3. What communication medium does it use?

It uses 75 Ohm coaxial cables terminated with BNC connectors.

4. How many drops can one module support?

One module supports a single drop. For additional drops, more modules must be used.

5. Is redundancy supported by this module?

While the module itself does not support redundancy, redundant configurations are possible with supporting architecture.

6. What is the recommended software for configuration?

Unity Pro or EcoStruxure Control Expert.

7. Can this module be hot-swapped?

No, it should only be inserted or removed when the rack is powered off.

8. What kind of status feedback does it offer?

It provides LED indicators for module status, I/O communication, and errors.

9. Does the module support hazardous area installation?

Yes, it holds ATEX and other certifications suitable for industrial zones.

10. How is the module powered?

It draws 5 V DC power from the Quantum backplane.

Related Models in the Same Series or Function

| Model | Description | Key Features |

|---|---|---|

| 140CRA21110C | DIO Drop Interface | Basic drop interface for Quantum RIO networks |

| 140CRA21120C | DIO Sub Interface | Remote I/O sub-interface for distributed architecture |

| 140CRA21210C | Enhanced DIO Sub Interface | Extended diagnostics and modular drop functionality |

| 140CRP93100 | RIO Head Adapter | Interfaces CPU with coaxial RIO drops |

| 140CRP93200 | Fiber-Based RIO Adapter | Enables long-distance communication over fiber |

| 140NOE77111 | Ethernet TCP/IP Module | Adds Ethernet interface to Modicon Quantum PLC |

Popular Schneider Electric Models from Other Product Lines

| Model | Category | Application |

|---|---|---|

| BMEP582040 | Modicon M580 CPU | High-end PAC with built-in Ethernet redundancy |

| TM251MESE | Modicon M251 Logic Controller | Compact PLC with Ethernet for machine automation |

| ATV930U75N4 | Altivar Process Drive | High-performance motor drive for pump/fan control |

| HMIGTO5310 | HMI Touchscreen Panel | 10.4” TFT color display for industrial operator control |

| NSX250N | Compact NSX Breaker | MCCB for industrial power distribution panels |

| BMXP342020 | Modicon M340 CPU | Flexible mid-range controller for hybrid control tasks |

Excellent PLC

Excellent PLC