| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

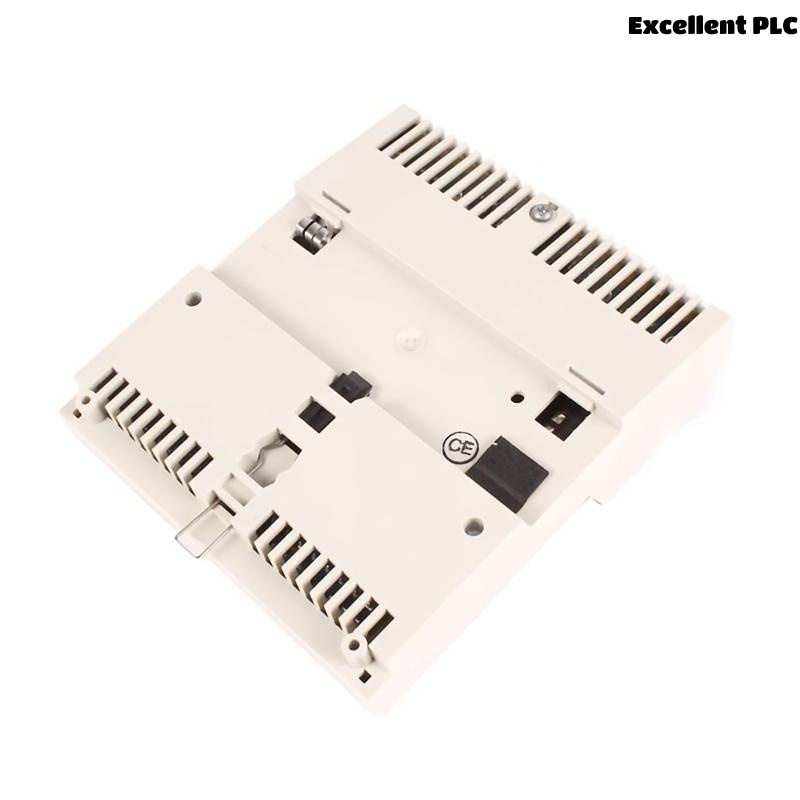

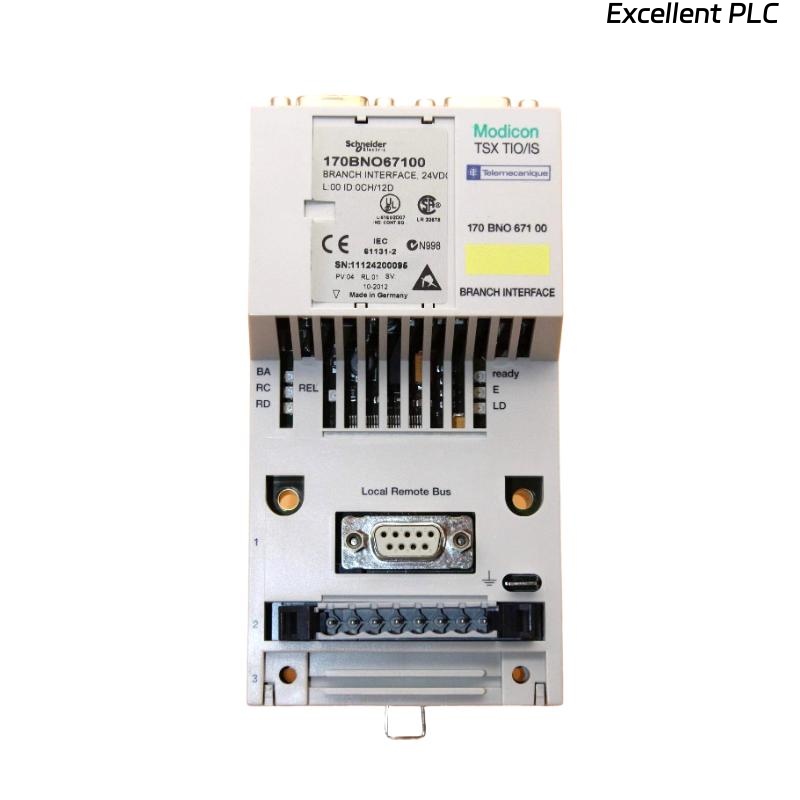

The Schneider Electric 170BAM09600 is a Base Analog Module from the Modicon Momentum series, designed to support the integration of analog I/O modules into distributed control systems. This versatile module serves as the interface between the Momentum I/O slice and the communication adapters (like Ethernet, Modbus TCP/IP, or serial modules), enabling analog input/output capabilities in compact, modular automation environments.

Engineered for industrial performance, the 170BAM09600 provides the essential analog signal routing functionality for up to 8 channels of input or output. Its streamlined DIN-rail mountable design and compatibility with a wide range of I/O modules make it a cornerstone in building scalable, distributed architectures, particularly in cost-sensitive or space-constrained applications.

Equipped with robust diagnostic features and rugged industrial compliance, the 170BAM09600 allows engineers to deploy reliable analog control in industries such as manufacturing, utilities, HVAC, water treatment, and infrastructure automation.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 170BAM09600 |

| Manufacturer | Schneider Electric |

| Product Type | Momentum Base Analog Module |

| Series | Modicon Momentum |

| I/O Support | Supports up to 8 analog I/O channels (depends on installed module) |

| Supported Modules | 170AAI series (analog input), 170AAO series (analog output) |

| Power Supply | Via communication adapter module (not direct) |

| Module Interface | Backplane bus for I/O communication |

| Connection Type | DIN rail mount with field wiring terminal base |

| Cable Length | 0.2 meters |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5% to 95% RH (non-condensing) |

| Electromagnetic Immunity | IEC 61000-4-2/3/4 compliant |

| Certifications | CE, UL, CSA, RoHS compliant |

| Dimensions (W x H x D) | 125 x 40 x 180 mm |

| Weight | 0.209 kg |

Product Applications

The 170BAM09600 module is widely used in analog data acquisition and process control in industrial environments. Its primary function is to provide a base for analog I/O modules and ensure communication between field signals and the processor or network adapter. Applications include:

-

Water and Wastewater Automation: Monitors and controls flow rates, pressure levels, and chemical dosing via analog sensors and actuators.

-

Food & Beverage Production: Manages temperature and flow controls in automated mixing, batching, and filling systems.

-

Building Automation: Interfaces with analog HVAC sensors for environmental monitoring and control.

-

Oil & Gas Processing: Collects analog signals from pressure, flow, and vibration sensors in remote field applications.

-

Energy Management: Used in substations and energy distribution for analog voltage and current signal acquisition.

-

Pharmaceutical Manufacturing: Controls precise temperature, humidity, and mixing processes using analog loops.

Product Advantages

-

Compact and Modular: Space-saving Momentum design with easy DIN rail mounting, suitable for distributed I/O architectures.

-

Flexible Analog Support: Compatible with a range of analog input/output modules, supporting various signal types and resolutions.

-

Seamless Integration: Easily interfaces with Ethernet or serial communication adapters for networked PLC systems.

-

Easy Maintenance: Hot-swappable I/O modules allow for minimal downtime during servicing or upgrades.

-

Industrial Reliability: Built to operate under harsh conditions, with strong EMC immunity and environmental compliance.

-

Field Wiring Simplification: Plug-in terminal bases reduce installation time and ensure reliable wiring connections.

-

High Accuracy & Precision: Supports modules capable of high-resolution analog conversion for precise control.

-

Diagnostic Capabilities: Enables error reporting, signal integrity monitoring, and simplified troubleshooting.

-

Energy Efficient: Low power consumption with centralized power supplied via communication adapters.

-

Future-Proof Platform: Designed to grow with expanding systems thanks to its modular and scalable architecture.

Frequently Asked Questions (FAQ)

-

Can the 170BAM09600 be used with both input and output analog modules?

Yes, it supports both analog input (e.g., 170AAI03000) and output (e.g., 170AAO25200) modules from the Momentum series. -

Does this base module include analog conversion circuitry?

No, the analog signal processing is handled by the installed I/O module. The base module facilitates communication and physical mounting. -

How does the 170BAM09600 communicate with a PLC processor?

It connects through a communication adapter module (e.g., 170ENT11001 for Ethernet) that links to the PLC. -

Is there a limitation on the type of analog signals supported?

The signal type (e.g., 0–10 V, 4–20 mA) is determined by the analog module plugged into the base, not by the base itself. -

Can the 170BAM09600 be used in standalone mode?

No, it requires a communication adapter and at least one I/O module to function as part of a control system. -

Is configuration software required for this base module?

No configuration is required at the base level. Configuration occurs through the communication adapter using Unity Pro or EcoStruxure Control Expert. -

What happens if the analog module is removed during operation?

The system will detect the module absence and flag a fault; analog data will stop being read or written. -

Can I use this module in hazardous environments?

While it meets industrial EMC and environmental standards, confirm specific certifications (ATEX, Class I Div 2) based on your application. -

Is hot swapping supported for the I/O modules mounted on the 170BAM09600?

Yes, hot swapping is supported, allowing modules to be replaced without powering down the system. -

What is the maximum number of analog signals that can be connected via this module?

It depends on the I/O module installed—typically up to 8 analog channels per module.

Related Models (Same Series or Function)

| Model Number | Description |

|---|---|

| 170AAI03000 | 8-channel analog input module, 4–20 mA |

| 170AAI52000 | 4-channel high-resolution analog input module |

| 170AAO25200 | 2-channel analog output module, 4–20 mA |

| 170ENT11001 | Ethernet TCP/IP communication adapter for Momentum |

| 170ADM35010 | 8-channel discrete input module, 24 VDC |

| 170ANR12091 | 12-point analog reference module for signal scaling |

Popular Schneider Models (Same Brand)

| Model Number | Description |

|---|---|

| TM241CEC24T | M241 Logic Controller with Ethernet and 24 I/O |

| BMEP584040 | M580 PAC CPU module with 4 Ethernet ports |

| BMXP342020 | Premium PLC CPU with built-in serial and Ethernet ports |

| HMIGTO5310 | 10.4” Magelis HMI touch panel with advanced graphics |

| ATV630D75N4 | 75 kW Altivar 630 drive for process applications |

| TM221ME16T | M221 Logic Controller with Modbus and Ethernet support |

Excellent PLC

Excellent PLC