| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

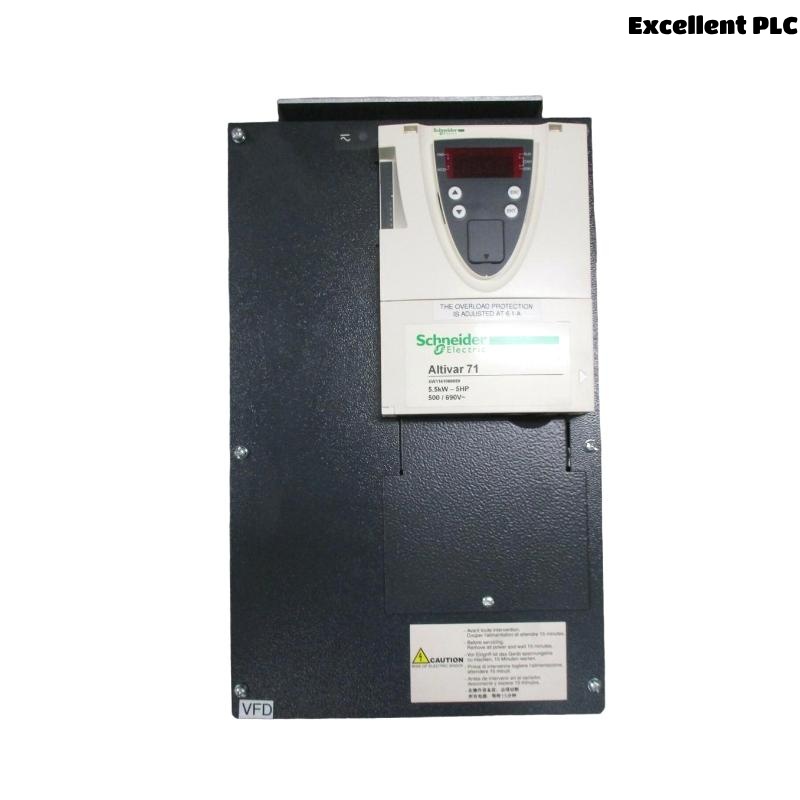

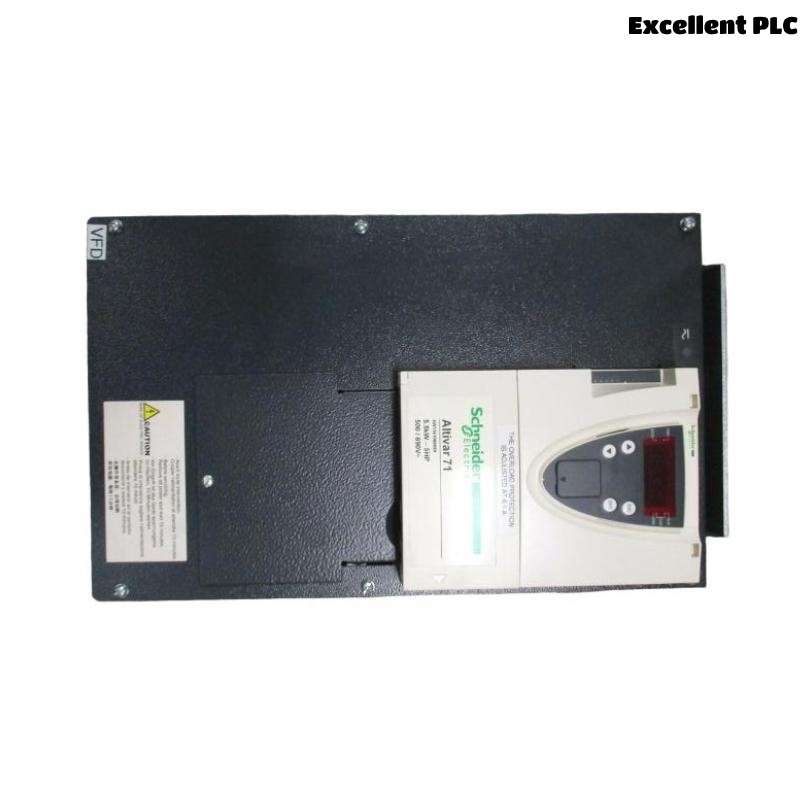

The Schneider Electric ATV71HU55Y is a robust, high-performance Variable Speed Drive (VSD) developed to handle demanding motor control tasks in complex industrial processes. It belongs to the Altivar 71 series, which is known for its precision motor control, advanced safety, and modularity.

This specific model, rated at 5.5 kW (7.5 HP), is engineered for three-phase 200–240V power systems, ideal for regions or applications that use lower voltage standards. With features like sensorless flux vector control, voltage/frequency ratio control, and flux vector control with feedback, it provides precise regulation of motor speed and torque in both synchronous and asynchronous motors.

Integrated Modbus and CANopen communications, Safe Torque Off (STO), multiple I/O options, and a compact design make the ATV71HU55Y a versatile solution for OEMs, system integrators, and end users.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | ATV71HU55Y |

| Brand | Schneider Electric |

| Series | Altivar 71 |

| Motor Power Rating | 5.5 kW (7.5 HP) |

| Input Voltage | 200–240 V AC, three-phase |

| Input Frequency | 50/60 Hz |

| Output Voltage | 0 to line voltage |

| Output Frequency | 0.1 to 599 Hz |

| Rated Output Current | 24 A |

| Control Modes | V/F, Sensorless Flux Vector, Flux Vector with Feedback |

| Integrated Communication | Modbus, CANopen |

| Communication Expansion | Profibus DP, Ethernet/IP, DeviceNet (via option modules) |

| Digital Inputs | 7 configurable |

| Analog Inputs | 3 (including one PT100) |

| Relay Outputs | 2 programmable |

| Analog Outputs | 2 |

| Safety Functions | Integrated Safe Torque Off (STO) |

| Cooling Method | Forced ventilation |

| Enclosure Rating | IP20 (with heatsink), IP21 (with optional kit) |

| Mounting Method | Wall-mounted or in panel enclosure |

| Operating Temperature | -10°C to +50°C (without derating) |

| Certifications | CE, UL, CSA, RoHS, IEC 61800-5-1 |

| Dimensions (H x W x D) | 420 x 236 x 240 mm |

| Weight | 30 kg |

Product Applications

-

Material Conveying Systems

Provides smooth and reliable speed control for conveyors, hoists, and lifts. -

Pumps and Fans

Suitable for variable torque applications such as centrifugal pumps and industrial fans. -

Textile Machinery

Offers precise control needed for synchronized motion in spinning, weaving, and dyeing units. -

Industrial Mixers and Agitators

Ideal for high torque start-up requirements and maintaining stable speed during load changes. -

HVAC Systems

Integrated PID control enhances energy efficiency and air/water flow management in buildings. -

Extruders and Printing Presses

Delivers accurate motor control essential for tension, alignment, and continuous processing.

Product Advantages

-

Designed for 200–240V Applications

Specially tailored for regions with lower voltage grids or machinery requiring low-voltage control. -

Versatile Control Options

Offers advanced motor control for asynchronous and synchronous motors across various modes. -

Integrated Safety

Built-in Safe Torque Off (STO) improves machine safety by immediately disabling motor torque. -

Flexible Communication

Modbus and CANopen built-in, with support for optional protocols for seamless integration. -

Energy Savings

Features like motor flux optimization and PID control help reduce energy consumption. -

Easy Configuration

User-friendly interface and SoMove software simplify commissioning and diagnostics. -

Scalable Design

Modular architecture enables adaptability with add-on cards and accessories.

Frequently Asked Questions (FAQ)

-

What voltage does the ATV71HU55Y support?

This model supports 200–240 V AC, three-phase input voltage. -

What is the rated power of this drive?

It is rated for 5.5 kW (7.5 HP) motors. -

Can it control synchronous motors?

Yes, it supports both synchronous and asynchronous motors. -

Is the drive compliant with global standards?

Yes, it meets CE, UL, CSA, RoHS, and IEC 61800-5-1 standards. -

What control methods are available?

V/F control, sensorless vector control, and flux vector control with feedback. -

Does it have built-in communication protocols?

Yes, Modbus and CANopen are integrated. Others can be added via expansion cards. -

How is motor safety ensured?

Through Safe Torque Off (STO), which disables motor torque during emergencies. -

Can it be used in enclosed panels?

Yes, it is suitable for panel mounting, with forced ventilation for cooling. -

What tools are available for programming?

The drive can be programmed using Schneider’s SoMove software or HMI terminals. -

Is it suitable for HVAC systems?

Absolutely — with its built-in PID control, it’s ideal for variable load applications like HVAC.

Related Models from the Altivar 71 Series

| Model | Description |

|---|---|

| ATV71HU30Y | 3.0 kW, 200–240 V drive for light-duty applications |

| ATV71HU75Y | 7.5 kW drive, similar voltage class with higher power |

| ATV71HD11Y | 11 kW heavy-duty version for higher load demands |

| ATV71HU40Y | 4.0 kW drive with extended I/O options |

| ATV71HD18Y | 18.5 kW drive for medium industrial machines |

| ATV71HU22Y | 2.2 kW compact model for simple automation tasks |

Popular Drives from Schneider Electric

| Model | Description |

|---|---|

| ATV320U15M2B | Altivar 320, 1.5 kW, single-phase input, compact VSD |

| ATV630D22N4 | Altivar Process 630, 22 kW, advanced energy saving drive |

| ATV212HU55N4 | 5.5 kW HVAC-optimized drive, Altivar 212 series |

| ATV12H037M2 | Altivar 12, 0.37 kW, small machine or pump applications |

| ATV61HU75N4 | 7.5 kW drive for building management systems |

| ATV930U55N4 | Altivar 930, 5.5 kW with Ethernet, designed for Industry 4.0 |

Excellent PLC

Excellent PLC