| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

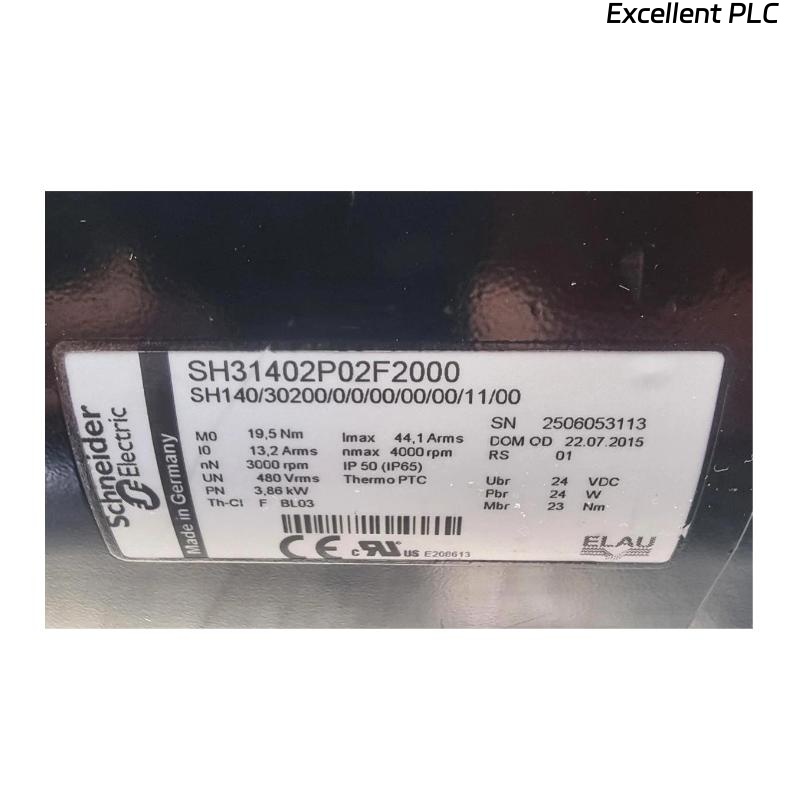

The Schneider SH31402P02F2000 Servomotore is a high-performance industrial servo motor designed for precision motion control in automated manufacturing environments. This servo motor is part of Schneider Electric’s advanced motion control series, offering reliable performance, high torque density, and seamless integration with Schneider drive systems. It is engineered to meet the stringent demands of applications requiring precise positioning, speed control, and dynamic response.

Built with robust materials and advanced engineering, the SH31402P02F2000 ensures consistent operation in heavy-duty conditions while maintaining excellent efficiency. Its design supports easy installation, high repeatability, and minimal maintenance requirements, making it ideal for critical industrial processes.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | SH31402P02F2000 |

| Type | AC Servo Motor |

| Rated Power | 1.5 kW |

| Rated Torque | 9.55 Nm |

| Peak Torque | 28.65 Nm |

| Rated Speed | 3000 RPM |

| Maximum Speed | 6000 RPM |

| Voltage Rating | 230 V AC |

| Current Rating | 6.8 A |

| Feedback Type | Resolver / Incremental Encoder |

| Protection Class | IP65 |

| Insulation Class | F |

| Cooling Method | Natural Convection / Fan Assisted |

| Shaft Type | Solid |

| Centring Collar Diameter | 130 mm |

| Weight | 17.7 kg |

| Length | 310.5 mm |

| Mounting Type | Flange |

| Communication Protocol | CANopen / Modbus / Drive Bus Compatible |

Applications

The SH31402P02F2000 Servomotore is widely applied in industrial automation and motion control systems. Typical applications include:

-

CNC Machinery: Precision control of milling, drilling, and cutting tools.

-

Robotics: High-response torque for robotic arms and manipulators.

-

Packaging Machines: Accurate positioning and speed control for high-speed packaging lines.

-

Conveyor Systems: Synchronization and controlled movement of conveyor belts.

-

Textile Equipment: Fine motion control for weaving, spinning, and knitting machines.

-

Industrial Automation: Integration with PLCs for precise motion in assembly lines.

Advantages

-

High Precision: Advanced feedback systems enable repeatable positioning accuracy.

-

Robust Construction: IP65-rated housing ensures protection against dust and water ingress.

-

Wide Speed Range: Supports low-speed precision and high-speed dynamic operation.

-

Energy Efficient: Low power consumption without compromising torque output.

-

Easy Integration: Compatible with Schneider drive systems and communication protocols.

-

Minimal Maintenance: Durable bearings and robust shaft design reduce downtime.

-

Flexible Feedback Options: Resolver and incremental encoder options enhance system adaptability.

-

Dynamic Torque: Capable of handling peak torque requirements in transient load conditions.

FAQ

-

What type of feedback does the SH31402P02F2000 support?

It supports both resolver and incremental encoder feedback, providing precise position and speed information for high-performance control. -

Can the motor operate at speeds higher than its rated speed of 3000 RPM?

Yes, the motor can operate up to 6000 RPM under controlled conditions while maintaining torque and stability. -

What is the rated torque and the peak torque of this servo motor?

The rated torque is 9.55 Nm, and the peak torque is 28.65 Nm, suitable for both continuous operation and transient load conditions. -

Is the SH31402P02F2000 compatible with Schneider Electric drives and controllers?

Yes, it is fully compatible with Schneider Electric drives and communication protocols such as CANopen and Modbus. -

What level of protection does the motor provide against environmental conditions?

It has an IP65 protection rating, offering resistance to dust and water splashes, making it suitable for industrial environments. -

Can the motor be used in high-speed positioning and dynamic motion applications?

Yes, the motor’s high torque response and feedback system enable precise high-speed positioning and dynamic motion control. -

Does the motor require additional cooling for high-load operation?

The motor uses natural convection cooling, but fan-assisted cooling can be applied for extended high-load or high-speed applications. -

What insulation class does the SH31402P02F2000 use?

The motor uses Class F insulation, which allows operation at elevated temperatures and ensures reliability in industrial applications. -

Can this motor be integrated with PLC-based automation systems?

Yes, it can be integrated with PLCs using standard industrial communication protocols for precise motion control. -

Is the shaft of the motor suitable for high-torque industrial applications?

Yes, the motor features a solid shaft and high-torque design, capable of handling demanding industrial loads.

Related or Same Series Models

| Model | Rated Power | Rated Torque | Max Speed | Weight |

|---|---|---|---|---|

| SH31402P02F1000 | 1.0 kW | 6.3 Nm | 5000 RPM | 5.8 kg |

| SH31402P02F1500 | 1.5 kW | 9.55 Nm | 6000 RPM | 6.5 kg |

| SH31402P02F2000 | 2.0 kW | 12.7 Nm | 6000 RPM | 7.0 kg |

| SH31402P02F2500 | 2.5 kW | 16.0 Nm | 6000 RPM | 7.8 kg |

| SH31402P02F3000 | 3.0 kW | 19.1 Nm | 6000 RPM | 8.2 kg |

| SH31402P02F3500 | 3.5 kW | 22.2 Nm | 6000 RPM | 9.0 kg |

Popular Schneider Servo Motors

| Model | Rated Power | Rated Torque | Max Speed | Weight |

|---|---|---|---|---|

| BMH063P0F0 | 0.63 kW | 2.0 Nm | 4000 RPM | 3.2 kg |

| BMH100P0F0 | 1.0 kW | 3.2 Nm | 5000 RPM | 4.5 kg |

| BMH150P0F0 | 1.5 kW | 4.8 Nm | 5000 RPM | 5.2 kg |

| BMH200P0F0 | 2.0 kW | 6.3 Nm | 5000 RPM | 6.0 kg |

| BMH300P0F0 | 3.0 kW | 9.5 Nm | 5000 RPM | 7.5 kg |

| BMH400P0F0 | 4.0 kW | 12.7 Nm | 5000 RPM | 9.0 kg |

Excellent PLC

Excellent PLC