| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

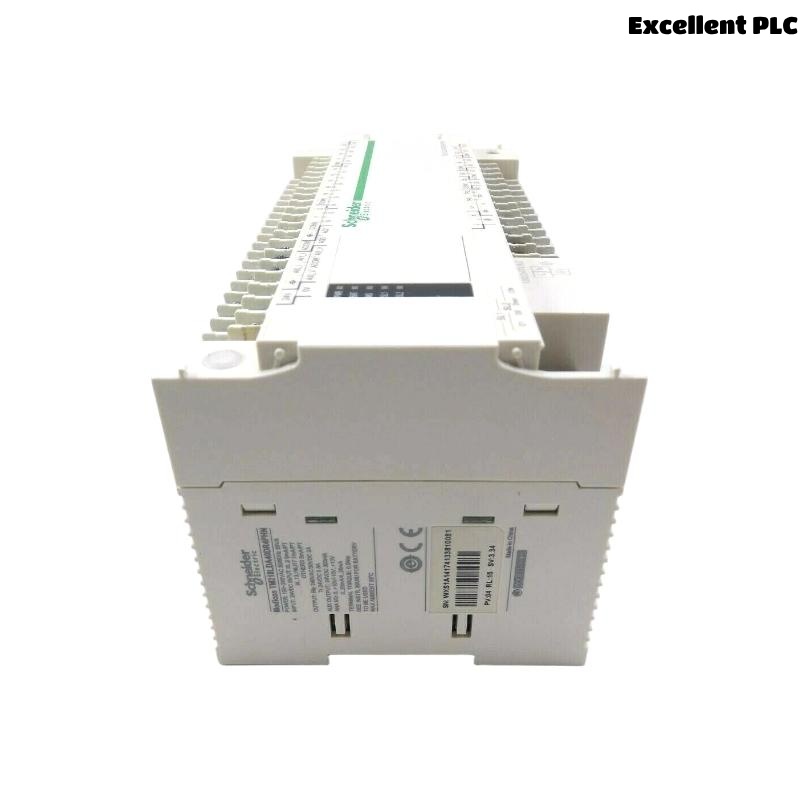

The Schneider Electric TM218LDA40DR4PHN is a Modicon M221 logic controller from the Modicon M2xx family, designed for cost-effective, compact, and scalable machine control. Tailored for original equipment manufacturers (OEMs) and machine builders, this controller provides both flexibility and performance in discrete and simple process automation applications.

Equipped with 40 I/O points (24 digital inputs and 16 relay outputs), two analog inputs, embedded Ethernet, and serial communication ports, this compact PLC simplifies installation while reducing wiring needs. With EcoStruxure Machine Expert (formerly SoMachine Basic) as its configuration environment, the M221 makes development, commissioning, and diagnostics quick and efficient.

Built to operate in harsh industrial environments, the TM218LDA40DR4PHN offers a powerful, all-in-one solution for control applications that demand reliability, connectivity, and ease of use.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Model | TM218LDA40DR4PHN |

| Product Family | Modicon M221 |

| CPU Type | Logic Controller |

| Number of Digital Inputs | 24 |

| Input Type | Sink/Source, 24V DC |

| Number of Digital Outputs | 16 (Relay type) |

| Relay Output Voltage | 24V DC / 240V AC |

| Relay Output Current | 2 A per point, 8 A per common |

| Analog Inputs | 2 (0–10V, 10-bit resolution) |

| Communication Ports | 1 Ethernet, 2 Serial (RS232/RS485 mini-DIN & RJ45) |

| USB Port | 1 Mini-B USB (programming) |

| Expansion Capability | Up to 7 TM3 expansion modules |

| Programming Software | EcoStruxure Machine Expert – Basic |

| Memory (Flash/RAM) | 256 KB Flash / 64 KB SRAM |

| Real-Time Clock | Integrated |

| Power Supply | 24 VDC |

| Power Consumption | < 6 W |

| Mounting | DIN rail or panel mounting |

| Operating Temperature | 0°C to +55°C (32°F to 131°F) |

| Storage Temperature | -40°C to +70°C |

| Protection Rating | IP20 |

| Certifications | CE, UL, cULus, EAC, RoHS |

| Dimensions (W x H x D) | 217 x 90 x 60 mm |

| Weight | 0.54 kg |

Applications

The TM218LDA40DR4PHN is ideally suited for a wide range of industrial and commercial applications, including:

-

Packaging Machinery – Manages conveyor systems, labeling units, and bagging machines.

-

Material Handling Systems – Controls sorting arms, lifting devices, and motorized tracks.

-

HVAC Control Systems – Used for regulating fans, pumps, dampers, and temperature zones.

-

Food & Beverage Automation – Automates batching, mixing, and filling lines.

-

Building Management – For access control, lighting, and energy metering systems.

-

Agricultural Automation – Manages irrigation, feeders, and ventilation in greenhouses or farms.

Advantages

-

Compact All-in-One Design: Integrated I/Os and communication ports eliminate the need for extra modules in small control systems.

-

Flexible Connectivity: With Ethernet, serial ports, and USB, it connects to a wide range of devices and networks.

-

Effortless Programming: The free EcoStruxure Machine Expert – Basic software allows intuitive programming with ladder logic, function block, and structured text.

-

Reliable Performance: Designed for long-term industrial use, with high MTBF and reliable relay outputs.

-

Expandable Architecture: Supports TM3 expansion modules to grow alongside machine requirements.

-

Cost-Effective: Delivers premium features at an affordable price point, reducing system costs.

-

Fast Installation and Commissioning: DIN rail mounting and plug-and-play expansion simplify setup.

-

Energy Efficient: Low power consumption with high reliability in 24/7 operations.

Frequently Asked Questions (FAQ)

1. What programming environment is used for the TM218LDA40DR4PHN?

It is programmed using EcoStruxure Machine Expert – Basic, which supports ladder, FBD, and ST languages.

2. How many I/O points are built-in?

It includes 24 digital inputs and 16 relay outputs, along with 2 analog inputs.

3. Can I expand the I/O capacity of this controller?

Yes, it supports up to 7 TM3 expansion modules.

4. What communication options are available?

It offers Ethernet, RS232/RS485, and a Mini USB for programming and diagnostics.

5. Is it suitable for harsh industrial environments?

Yes, it is built for industrial use, with IP20 protection, and operates from 0°C to +55°C.

6. Does it include a real-time clock?

Yes, the controller has a built-in real-time clock for time-based control and logging.

7. What is the power supply requirement?

It operates on 24V DC power supply.

8. Can it be mounted on a panel?

Yes, it supports both DIN rail and panel mounting options.

9. Is it certified for global use?

Yes, it holds certifications including CE, UL, cULus, EAC, and RoHS compliance.

10. What is the function of the Ethernet port?

The Ethernet port enables remote monitoring, Modbus TCP communication, and integration with HMI/SCADA systems.

Related Models in the Same Series

| Model | Description | I/O Count | Output Type | Communication |

|---|---|---|---|---|

| TM218LDA24DR | M221 Logic Controller, 24 I/O | 14 DI / 10 DO | Relay | Serial, USB |

| TM221CE16R | M221 Logic Controller, Ethernet + Relay | 8 DI / 8 DO | Relay | Ethernet, USB |

| TM221C40R | M221 Logic Controller, High I/O Count | 24 DI / 16 DO | Relay | Ethernet, Serial, USB |

| TM221ME16T | M221 Logic Controller, Transistor Output | 8 DI / 8 DO | Transistor | Ethernet, Serial, USB |

| TM221M16R | M221 Basic Controller, Compact Form | 8 DI / 8 DO | Relay | USB, Serial |

| TM218LDA28DT | M221 Controller, 28 I/O, Transistor Output | 16 DI / 12 DO | Transistor | Ethernet, Serial, USB |

Popular Models from Schneider Electric

| Model | Product Type | Description | Application |

|---|---|---|---|

| BMXP342020 | Modicon M340 PLC CPU | High-performance CPU for M340 automation | Advanced machine/process control |

| ATV320U22N4B | Altivar 320 Variable Speed Drive | Compact drive for motors (2.2 kW) | Motor control |

| HMISTU855 | HMI Touch Panel | 5.7” color display with touchscreen | Operator interface |

| TM221CE24R | Modicon M221 PLC | 24 I/O relay version with Ethernet | OEM/machine builders |

| TSXP573634M | Modicon Premium PLC CPU | Advanced CPU for high-speed processes | Infrastructure & manufacturing |

| BMXDDO1602 | Digital Output Module | 16-channel output module for M340 | I/O expansion |

Excellent PLC

Excellent PLC