| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

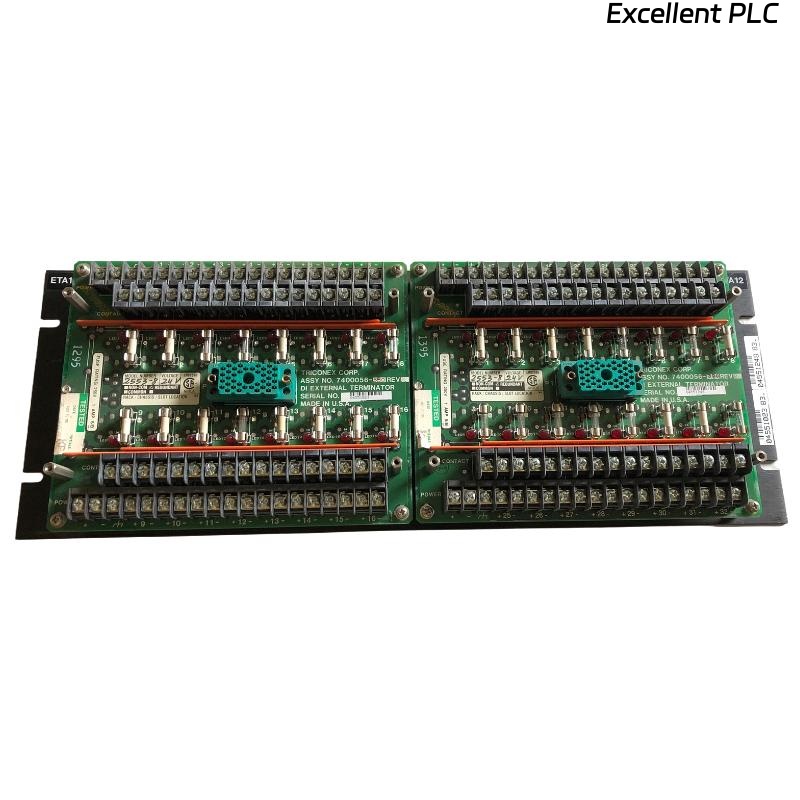

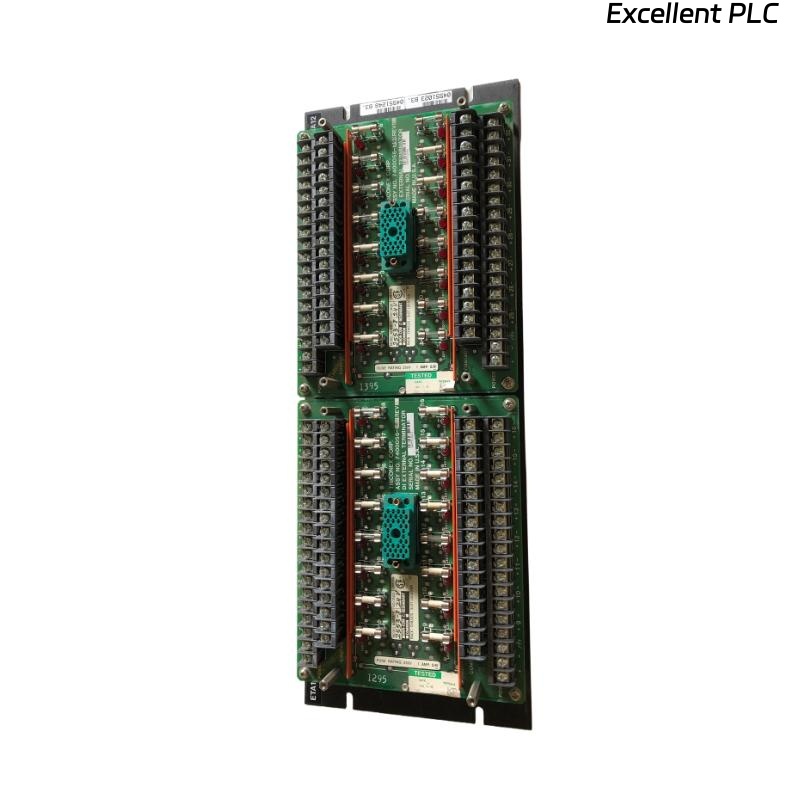

Product Introduction

The Triconex 3000110-360 Central Processing Unit (CPU) is a high-performance, fault-tolerant processing module designed for safety-critical industrial applications. It is part of the Triconex 3000 series, renowned for delivering uncompromising reliability in environments where process safety, availability, and integrity are paramount. The CPU provides deterministic control, real-time diagnostics, and seamless integration with Triconex I/O modules and redundant systems to ensure continuous and safe operation.

This processor is engineered with triple-modular redundancy (TMR) architecture, allowing the system to detect and correct errors autonomously, significantly reducing the risk of system failures. The Triconex 3000110-360 CPU is widely used in sectors like oil and gas, petrochemical, power generation, and other critical process industries where downtime or malfunction can have catastrophic consequences.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3000110-360 |

| Processor Type | Triconex Triple Modular Redundant CPU |

| Input Voltage | 24 VDC (typical) |

| Power Consumption | 35 W (typical), 45 W (max) |

| Communication Interfaces | Triconex Bus, Ethernet, Modbus TCP/IP optional |

| Redundancy | Triple Modular Redundancy (TMR) |

| Memory | 256 MB Flash, 512 MB RAM |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Diagnostics | Continuous self-monitoring and error correction |

| Safety Integrity Level (SIL) | SIL 3 certified |

| Dimensions (W x H x D) | 107 × 250 × 280 mm |

| Weight | 3.18 kg |

| Certifications | ATEX, IEC61508, CE |

Applications

The Triconex 3000110-360 CPU is used in various safety-critical and high-reliability industrial applications:

-

Oil and Gas Platforms – Supervisory control and emergency shutdown (ESD) systems.

-

Petrochemical Plants – Process safety monitoring and hazardous area automation.

-

Power Generation – Turbine, generator, and boiler safety systems.

-

Chemical Industry – Leak detection, process interlock, and safety instrumented systems (SIS).

-

Mining and Metals – Critical machinery protection and automation control.

-

Nuclear Facilities – Reactor protection and control safety systems.

Advantages

The Triconex 3000110-360 CPU offers a range of technical and operational benefits:

-

Fault Tolerant Architecture – Triple modular redundancy ensures system integrity even in the event of hardware faults.

-

High Reliability – Designed for 24/7 operation in critical industrial environments.

-

Real-Time Diagnostics – Continuous monitoring allows predictive maintenance and rapid fault detection.

-

Seamless Integration – Compatible with the full Triconex 3000 series, including I/O modules and communication interfaces.

-

SIL 3 Certified – Meets stringent safety requirements for critical process control applications.

-

Scalability – Supports networked redundant systems for large, distributed control systems.

-

Data Logging and Security – Non-volatile memory ensures historical data retention and operational traceability.

FAQ

-

What type of fault detection does the 3000110-360 CPU use?

It uses Triple Modular Redundancy (TMR) to detect and correct single-point faults in real time. -

Can this CPU be integrated into a hot standby system?

Yes, it supports hot standby configurations with seamless failover. -

What kind of real-time communication protocols are supported?

Triconex Bus is standard, and Ethernet with Modbus TCP/IP is optionally supported. -

How does the CPU handle software updates without downtime?

The system supports online firmware upgrades via redundant CPU modules to maintain operation. -

Is the 3000110-360 CPU compatible with previous Triconex 3000 series modules?

Yes, it is backward compatible with most legacy I/O and communication modules. -

How is safety ensured during a module failure?

The CPU automatically isolates the failed module while continuing operation using TMR redundancy. -

What is the maximum number of I/O points supported?

Up to 16,000 I/O points can be managed in a networked Triconex system configuration. -

Can this CPU operate in extreme environmental conditions?

Yes, it operates reliably from 0°C to 60°C, with storage from -40°C to 85°C. -

How is cybersecurity handled on the 3000110-360 CPU?

The system provides role-based access control, secure communication channels, and audit logging for critical operations. -

What diagnostic features are available for preventive maintenance?

Continuous self-monitoring, event logging, error reporting, and redundant module comparison are built-in for predictive maintenance.

Related or Same-Series Models

| Model Number | Description |

|---|---|

| 3000110-100 | Standard Triconex CPU, lower performance |

| 3000110-200 | Redundant CPU for small-scale systems |

| 3000110-220 | Mid-performance CPU with enhanced memory |

| 3000110-240 | CPU with extended diagnostics |

| 3000110-300 | High-performance CPU with faster processing |

| 3000110-360E | Enhanced CPU version for extreme environments |

Popular Triconex Brand Models

| Model Number | Description |

|---|---|

| 3000080-100 | Triconex 3000 I/O Module, standard version |

| 3000080-200 | High-density I/O module |

| 3000120-360 | Triconex Power Supply Module |

| 3000140-360 | Triconex Communication Interface Module |

| 3000180-360 | Triconex System Chassis |

| 3000210-360 | Triconex Redundant CPU Controller Module |

Excellent PLC

Excellent PLC