| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

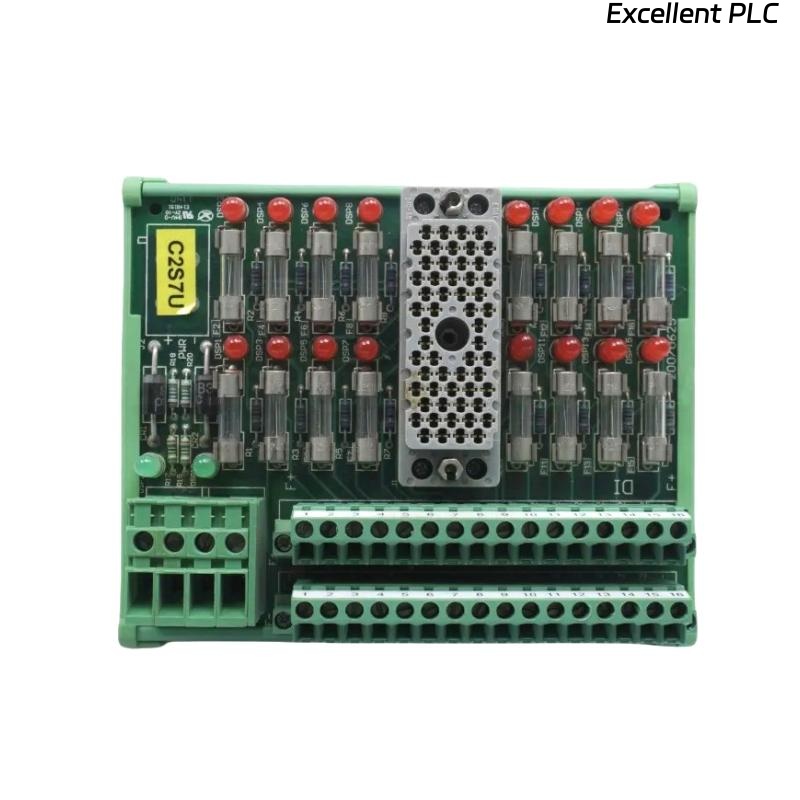

The Triconex 3000290-380 Backplane Module is a fundamental component within the Triconex safety instrumented system, serving as the main communication backbone for system modules installed in the rack. This backplane module facilitates data transfer, power distribution, and synchronization between the various modules such as processors, I/O, and communication interfaces. Designed to ensure fault tolerance and high reliability, the 3000290-380 supports the robust operational requirements of critical safety applications across industries. With high-quality connectors and a rigid construction, the backplane ensures stable and secure connections that maintain signal integrity, enabling the Triconex system to function seamlessly in demanding environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Triconex 3000290-380 |

| Function | Backplane Module |

| Number of Slots | Typically 6 or 8 slots (model-dependent) |

| Signal Type | Digital communication and power distribution |

| Operating Temperature Range | 0°C to 70°C |

| Storage Temperature Range | -40°C to 85°C |

| Dimensions (W × H × D) | 305 × 170 × 90 mm |

| Weight | 1.5 kg |

| Connector Type | High-reliability edge connectors |

| Mounting | Rack-mounted |

| Compliance | SIL 3 compliant |

Applications

The Triconex 3000290-380 Backplane Module is widely used in safety-critical environments where fault-tolerant and dependable system communication is required. Common application areas include:

-

Central backbone for Triconex safety instrumented systems in oil and gas facilities

-

Integration platform for safety control in petrochemical plants

-

Power plants’ safety system rack interconnections

-

Chemical manufacturing safety system architectures

-

Pharmaceutical industry safety automation systems

-

Critical infrastructure monitoring and control

Advantages

-

Robust Connectivity: Provides stable and secure inter-module communication paths within the system rack.

-

High Reliability: Engineered for fault-tolerant operation supporting SIL 3 safety levels.

-

Efficient Power Distribution: Supplies power evenly to all connected modules, ensuring consistent operation.

-

Durable Design: Rigid construction withstands mechanical stress and vibration typical in industrial environments.

-

Easy Installation: Designed for straightforward integration into standard Triconex racks.

-

Signal Integrity: High-quality connectors minimize noise and maintain data accuracy.

-

Wide Operating Range: Supports operation in diverse environmental conditions from 0°C to 70°C.

-

System Scalability: Supports multiple slots allowing flexible system expansion.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Triconex 3000290-380 backplane?

It serves as the main communication and power distribution backbone for modules within a Triconex rack. -

How many module slots does the backplane support?

Typically, it supports 6 to 8 slots depending on the exact model and configuration. -

Is the backplane compliant with safety standards?

Yes, it meets SIL 3 certification, suitable for high-integrity safety systems. -

What type of connectors are used on this backplane?

High-reliability edge connectors are used to ensure secure and noise-free connections. -

What is the operating temperature range of the backplane?

The module is designed to operate between 0°C and 70°C. -

Can the backplane distribute power to all connected modules?

Yes, it provides consistent power distribution to every installed module. -

Is the backplane compatible with all Triconex modules?

It is compatible with most Triconex processors, I/O, and communication modules designed for this rack type. -

How does the backplane maintain signal integrity?

Through high-quality connectors and careful design minimizing electromagnetic interference. -

Can the backplane be used for system expansion?

Yes, it supports multiple slots, allowing easy addition of modules for system scalability. -

What mounting options are available for the backplane?

It is designed for secure rack mounting inside Triconex system cabinets.

Recommended Related Models (Same Series or Similar Functionality)

| Model | Description | Slots Supported | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|

| Triconex 3000290-370 | Earlier version backplane module | 6 slots | 1.4 | 300 × 165 × 85 |

| Triconex 3000290-390 | Enhanced backplane module | 8 slots | 1.6 | 310 × 175 × 95 |

| Triconex 3000290-400 | High-capacity backplane module | 10 slots | 1.8 | 320 × 180 × 100 |

| Triconex 3000290-350 | Compact backplane for smaller racks | 4 slots | 1.1 | 280 × 150 × 80 |

| Triconex 3000290-360 | Standard backplane with integrated diagnostics | 6 slots | 1.5 | 305 × 170 × 90 |

| Triconex 3000290-370B | Backplane module with extended temperature | 6 slots | 1.5 | 305 × 170 × 90 |

Popular Triconex Models (Other Hot Products)

| Model | Application Area | Key Features | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| Triconex 3302 | Safety controller | SIL 3 certified, redundant design | 150 × 200 × 300 | 3.5 |

| Triconex 3502 | Safety system controller | Modular and fault tolerant | 160 × 210 × 310 | 3.8 |

| Triconex 3406 | Digital and analog I/O module | High-speed, flexible I/O | 35 × 170 × 220 | 1.2 |

| Triconex 3407 | Analog output module | Precision analog signal generation | 35 × 170 × 220 | 1.3 |

| Triconex 8306E | Power supply module | SIL 3 compliant, reliable power | 35 × 170 × 220 | 1.2 |

| Triconex 3304 | Communication module | Network diagnostics and communication | 40 × 180 × 230 | 1.1 |

Excellent PLC

Excellent PLC