| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

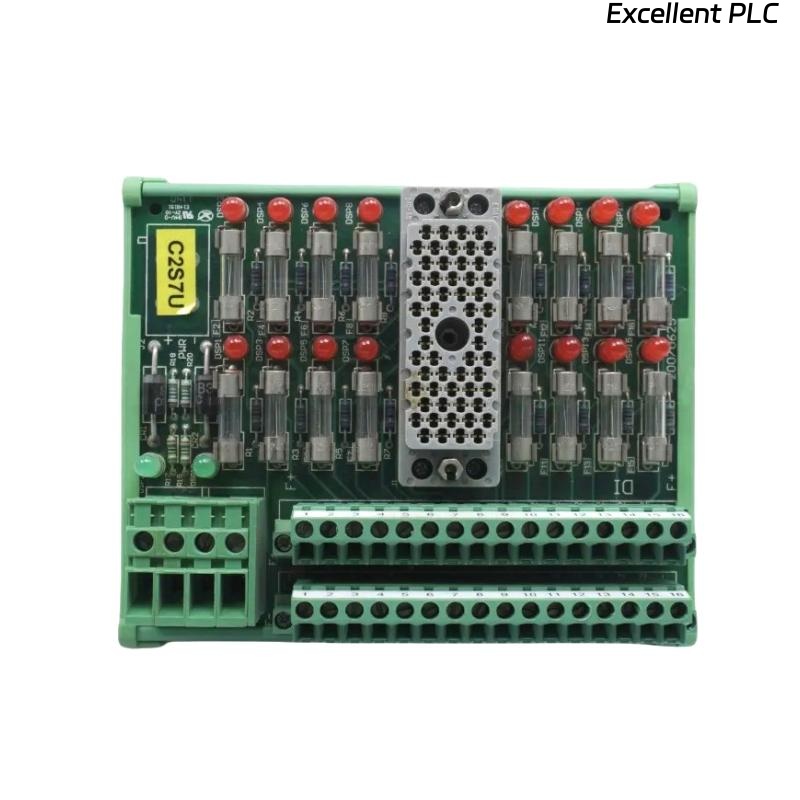

Triconex 3002 Product Overview

The Triconex 3002 is a highly reliable digital input module designed for use within Triconex’s Tricon safety systems. It plays a crucial role in monitoring field devices, collecting digital signals, and providing inputs to safety controllers. Known for its robust design, the Triconex 3002 ensures that safety-critical systems are able to process and respond to signals in real-time, which is vital for industrial operations where uptime and safety are essential. The module is an integral part of the Tricon safety system’s architecture and is used widely in sectors like oil & gas, chemical, power generation, and manufacturing.

Product Parameters

| Parameter | Specification |

|---|---|

| Product Name | Triconex 3002 |

| Module Type | Digital Input Module |

| Input Channels | 8 Digital Inputs |

| Input Voltage Range | 19.2V DC – 30V DC |

| Input Type | 24V DC Binary (On/Off) |

| Power Supply | 24V DC ±20% |

| Power Consumption | 2.5 W |

| Dimensions (HxWxD) | 150 x 130 x 35 mm |

| Weight | 0.5 kg |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Protection Class | IP20 |

| Certification | CE, UL, SIL 3 |

Product Description

The Triconex 3002 module is a part of the Tricon safety instrumented system, which is designed to provide high levels of safety for industrial processes. It receives 24V DC binary input signals (On/Off) and is highly reliable in mission-critical applications. The module’s SIL 3 certification guarantees its ability to maintain safety and integrity even under adverse conditions, making it perfect for industries where operational safety is crucial.

The Triconex 3002 is used to monitor various types of field devices, such as limit switches, pressure switches, or emergency stop buttons. The integration of this module into a Triconex system ensures that digital signals are quickly processed, allowing for immediate response actions in case of system anomalies.

Applications

The Triconex 3002 is employed in a variety of industries where process safety is paramount:

- Oil & Gas Industry: Used in monitoring critical components such as pumps, valves, and gas detectors to ensure safety and reliability in hazardous environments.

- Chemical Manufacturing: Ideal for controlling hazardous chemical processes, including batch reactors and storage tanks.

- Power Generation: Ensures the integrity of power plant operations by providing fail-safe inputs from field devices such as pressure and flow switches.

- Pharmaceutical Industry: Monitors critical alarms and conditions in manufacturing and processing areas.

- Mining & Metals: Provides safety in automated systems, such as conveyor belts and crushing machines, in mining operations.

- Water Treatment: Utilized in process control for water treatment plants, ensuring that equipment operates within safe parameters.

- Refineries: Ensures the proper operation of safety systems in refining processes, such as pressure relief valves and emergency shutdown systems.

Product Advantages

- High Safety Integrity: Certified for SIL 3, ensuring maximum safety in critical applications.

- Reliable Performance: The module’s design is built for continuous operation, even in harsh environments, ensuring long-term reliability.

- Versatility: The Triconex 3002 can handle a wide variety of input signals, making it adaptable to different types of field devices.

- Compact Design: The module’s compact size makes it easy to integrate into existing safety systems, even in space-constrained environments.

- Wide Temperature Range: The module can operate in a broad temperature range from -20°C to +60°C, suitable for both indoor and outdoor applications.

- Easy Integration: Designed to integrate seamlessly into the Triconex system, simplifying installation and reducing setup time.

- Cost-Effective: Provides high levels of safety and reliability without compromising on performance or cost.

Latest Reports and News

- Title: “Triconex 3002: Enhancing Safety with Advanced Digital Input Modules for Industrial Applications”

- Title: “Triconex Introduces 3002 Module for Improved Signal Processing in Safety Systems”

- Title: “Next-Generation Safety: Triconex 3002 Redefines Real-Time Monitoring in Hazardous Industries”

- Title: “Triconex 3002: A Critical Component in the Future of Automation and Safety in Oil & Gas”

- Title: “Triconex 3002 Module: A Cost-Effective Solution for Safety Systems with SIL 3 Certification”

Frequently Asked Questions (FAQ)

-

What is the Triconex 3002 used for?

- It is a digital input module used for monitoring and processing 24V DC binary signals from field devices in safety-critical systems.

-

How many input channels does the Triconex 3002 have?

- The module features 8 digital input channels.

-

What is the voltage range supported by the Triconex 3002?

- It supports an input voltage range of 19.2V DC to 30V DC.

-

What is the weight of the Triconex 3002 module?

- The module weighs 0.8 kg.

-

What certification does the Triconex 3002 have?

- It is certified for SIL 3, ensuring high levels of safety for critical applications.

-

What is the operating temperature range of the Triconex 3002?

- The operating temperature range is from -20°C to +60°C.

-

Can the Triconex 3002 be used in outdoor applications?

- Yes, it can be used in outdoor applications, as it can operate within a broad temperature range and is rated to handle industrial environments.

-

How many digital inputs can the Triconex 3002 handle?

- The module can handle 8 digital input signals.

-

What industries typically use the Triconex 3002 module?

- The Triconex 3002 is widely used in industries such as oil & gas, chemical manufacturing, power generation, and pharmaceuticals.

-

Is the Triconex 3002 easy to integrate into existing systems?

- Yes, it is designed for easy integration into Tricon safety systems, reducing setup time and ensuring smooth operation.

Recommended Related Models

| Model | Description |

|---|---|

| Triconex 3003 | Digital Output Module with 8 outputs for safety systems |

| Triconex 3010 | Analog Input Module for monitoring critical process parameters |

| Triconex 3020 | Combined I/O module for digital and analog inputs/outputs |

| Triconex 3100 | Safety controller with enhanced processing capabilities |

| Triconex 3300 | High-density I/O module for large-scale safety systems |

| Triconex 3050 | Expansion module with additional digital inputs |

| Triconex 3200 | Advanced analog I/O module for precise control applications |

| Triconex 3060 | Digital I/O module for emergency shutdown systems |

| Triconex 3055 | Interface module for connecting field devices to the safety system |

| Triconex 3070 | Safety relay module for integration with Triconex controllers |

Popular Triconex Models

| Model | Description |

|---|---|

| Triconex 3600 | High-performance safety controller for large applications |

| Triconex 3500 | Modular safety controller for flexible configurations |

| Triconex 3700 | Advanced control and safety system for process industries |

| Triconex 4000 | Large-scale safety system controller for complex processes |

| Triconex 3900 | Safety solution for high-end, mission-critical systems |

| Triconex 3300 | Modular and scalable solution for industrial safety control |

| Triconex 3800 | High-integrity safety system with integrated diagnostics |

| Triconex 3200 | Digital I/O system for enhanced process safety performance |

| Triconex 3100 | A versatile controller for applications requiring fast response times |

| Triconex 3150 | Compact controller for small to medium-sized industrial systems |

Excellent PLC

Excellent PLC