| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

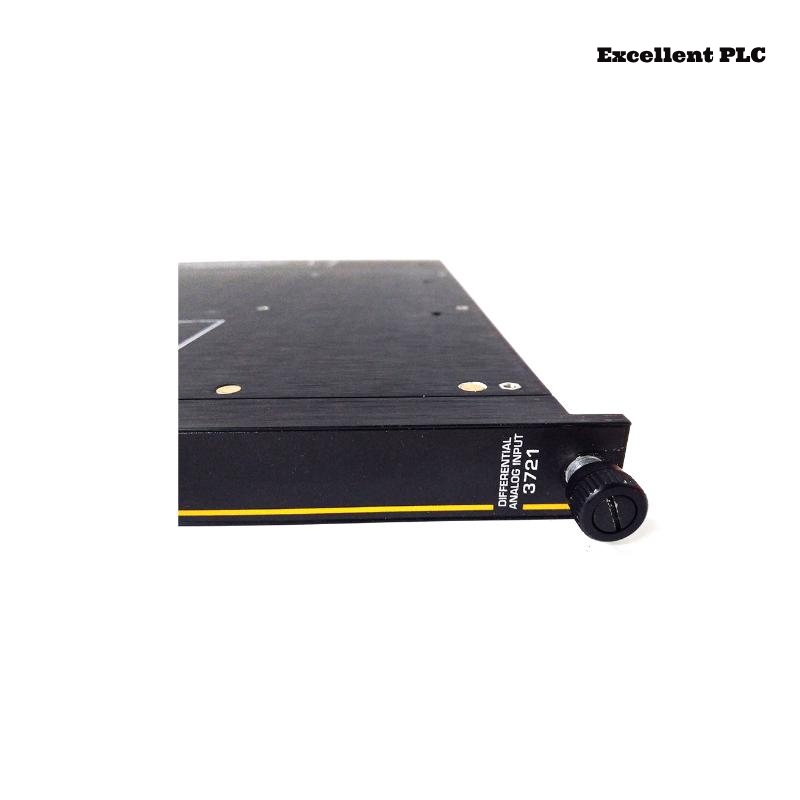

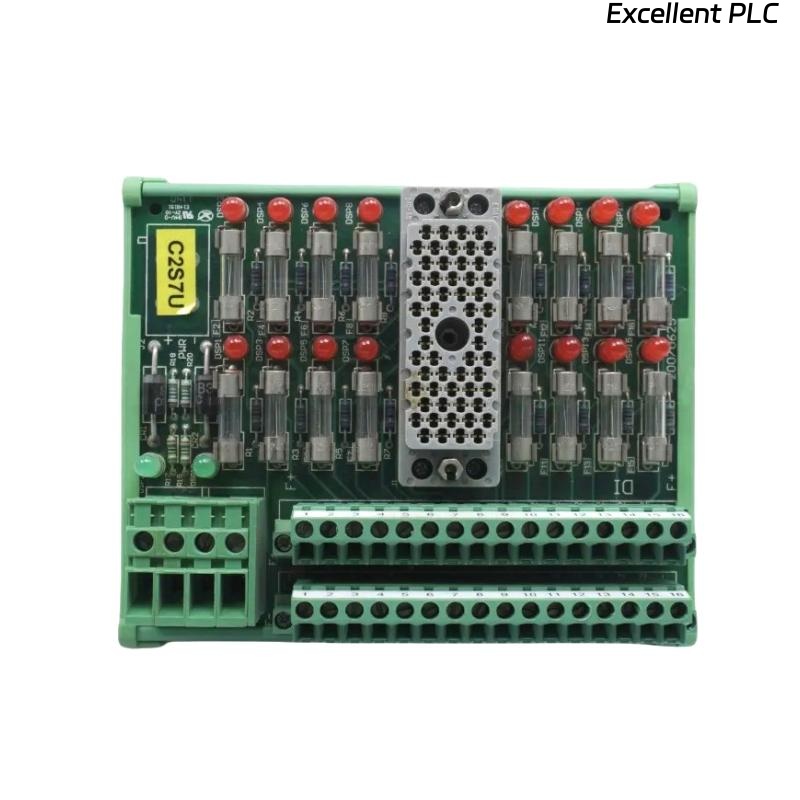

The Triconex 3721 Analog Input Module is an essential part of Triconex’s advanced safety system solutions, designed to process multiple analog input signals from field devices and sensors in safety-critical industrial processes. This module is engineered to offer high accuracy, reliability, and performance under the harshest conditions. Typically deployed in environments where safety and reliability are paramount, such as oil and gas, chemical processing, and power generation, the 3721 ensures that crucial parameters like temperature, pressure, and flow rates are accurately monitored and controlled.

This module is built to integrate seamlessly into Triconex’s safety system and communicates using standard protocols such as TriStation and Modbus, allowing it to fit into most control system architectures. With a focus on redundancy, fault tolerance, and high-precision data conversion, the Triconex 3721 is an ideal solution for applications that require real-time, high-performance control.

Product Specifications

| Specification | Details |

|---|---|

| Model | Triconex 3721 |

| Input Type | 8 Analog Inputs |

| Input Range | -10V to +10V |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Isolation | 250V RMS (channel-to-channel) |

| Communication Protocol | TriStation, Modbus |

| Operating Temperature | -20°C to +70°C |

| Power Supply | 24V DC |

| Dimensions (L x W x H) | 185 x 135 x 45 mm |

| Weight | 1.36 Kg |

| Mounting Type | Rack-mounted |

| Certification | UL, CE, CSA |

| Expected Life Span | 5+ years |

Product Applications

The Triconex 3721 Analog Input Module is designed for use in a wide range of industries where precise analog signal processing is critical. Its main applications include:

-

Oil & Gas: Used to monitor key process variables such as pressure, temperature, and flow rates in upstream and downstream operations.

-

Chemical and Petrochemical Processing: Provides highly accurate analog measurements to control chemical reactions and product quality.

-

Power Generation: Measures parameters like fuel flow, steam pressure, and turbine temperature to ensure stable and safe operations in power plants.

-

Water Treatment: Monitors water quality parameters and chemical levels in water treatment facilities to ensure regulatory compliance.

-

Manufacturing: Ensures that manufacturing processes are maintained within the desired safety limits by measuring physical properties such as temperature and pressure.

Product Advantages

-

High Reliability: Built for continuous operation even under demanding conditions, with built-in redundancy to ensure the safety system remains operational during failure scenarios.

-

Precise Data Conversion: With 16-bit resolution, the module offers highly accurate data conversion for better process control.

-

Wide Input Range: The module supports a wide input range of -10V to +10V, making it versatile for a variety of industrial applications.

-

Fault-Tolerant Design: The module is designed to be fault-tolerant, ensuring that if one part of the system fails, the overall safety system continues to function properly.

-

Easy Integration: The Triconex 3721 is compatible with TriStation and Modbus communication protocols, allowing it to integrate smoothly with existing control systems.

-

Compact and Efficient: Its compact design allows for easy installation in space-constrained environments without compromising on performance or functionality.

Latest News Titles

-

“Triconex 3721: Pioneering Analog Input Solutions for Critical Process Control”

-

“Ensuring Safety in Chemical Plants with Triconex 3721 Analog Input Module”

-

“How the Triconex 3721 Ensures Precision in Power Plant Monitoring”

-

“Advanced Analog Measurement: Triconex 3721 for the Oil & Gas Industry”

-

“Triconex 3721 Module: Reliable Data Conversion in High-Risk Environments”

-

“Triconex Unveils New 3721 Analog Input Module for Enhanced Safety Systems”

-

“Why the Triconex 3721 is the Go-To Analog Input Module for Industrial Safety”

-

“Triconex 3721: A Critical Component in Modern Safety Instrumented Systems”

-

“Raising the Bar in Analog Control: The Triconex 3721 for Process Automation”

-

“The Triconex 3721: Leading the Charge in Industrial Process Safety”

FAQ

-

What is the input range for the Triconex 3721?

-

The module supports an input range from -10V to +10V.

-

-

How many analog inputs can the Triconex 3721 module process?

-

The module has the capacity to process 8 analog inputs.

-

-

What is the resolution of the Triconex 3721 module?

-

The Triconex 3721 provides 16-bit resolution, ensuring high accuracy in signal conversion.

-

-

What is the power supply requirement for the Triconex 3721?

-

The module requires a 24V DC power supply for operation.

-

-

What type of isolation does the Triconex 3721 provide?

-

The module offers 250V RMS isolation between channels for enhanced safety and signal integrity.

-

-

What communication protocols are supported by the Triconex 3721?

-

The Triconex 3721 supports TriStation and Modbus protocols for communication.

-

-

What is the operating temperature range of the Triconex 3721 module?

-

The module operates in a temperature range of -20°C to +70°C.

-

-

Can the Triconex 3721 module be mounted in a standard rack?

-

Yes, the Triconex 3721 is designed for rack-mounted installation.

-

-

What certifications does the Triconex 3721 have?

-

The module is certified by UL, CE, and CSA, meeting global safety standards.

-

-

What industries commonly use the Triconex 3721 module?

-

The module is commonly used in industries such as oil & gas, power generation, chemical processing, and manufacturing.

Recommended Models (Same Series/Related Models)

| Model | Specification | Features |

|---|---|---|

| Triconex 3720 | 8 Analog Inputs, 24V DC, 16-bit resolution | Reliable data conversion, flexible input ranges |

| Triconex 3730 | 4 High-Speed Digital Inputs, 24V DC | Fast processing for safety-critical digital inputs |

| Triconex 3750 | 8 Thermocouple Inputs | Ideal for temperature measurement in hazardous areas |

| Triconex 3760 | 8 RTD Inputs | Advanced temperature control |

| Triconex 3780 | 16 Analog Inputs, 12-bit resolution | High-channel density, precise signal processing |

| Triconex 3790 | 4 High-Speed Digital Outputs | Optimized for output control in fast-response systems |

| Triconex 3700 | 4 Analog Inputs, 24V DC | Compact and efficient input module |

| Triconex 3704 | 8 Digital Inputs, 24V DC | Ideal for safety systems requiring digital inputs |

Popular Models from Triconex

| Model | Specification | Features |

|---|---|---|

| Triconex 3008 | 8 Digital Outputs, 24V DC, 16-bit | High-reliability outputs for safety-critical systems |

| Triconex 3100 | 4 Digital Inputs, 4 Digital Outputs, 24V DC | Versatile I/O for industrial process control |

| Triconex 4310 | 16 Digital Inputs, 24V DC | Flexible digital input module |

| Triconex 4400 | 4 Analog Outputs, 24V DC | Precise output control in process automation |

| Triconex 4500 | Safety PLC Processor | Core controller for safety instrumented systems |

| Triconex 4600 | Redundant Power Supply Module | Ensures continuous operation in critical applications |

| Triconex 5000 | 8 Digital Outputs, 24V DC | Reliable outputs for industrial safety systems |

| Triconex 5500 | High-Speed I/O Module | Designed for real-time process monitoring |

Excellent PLC

Excellent PLC