| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

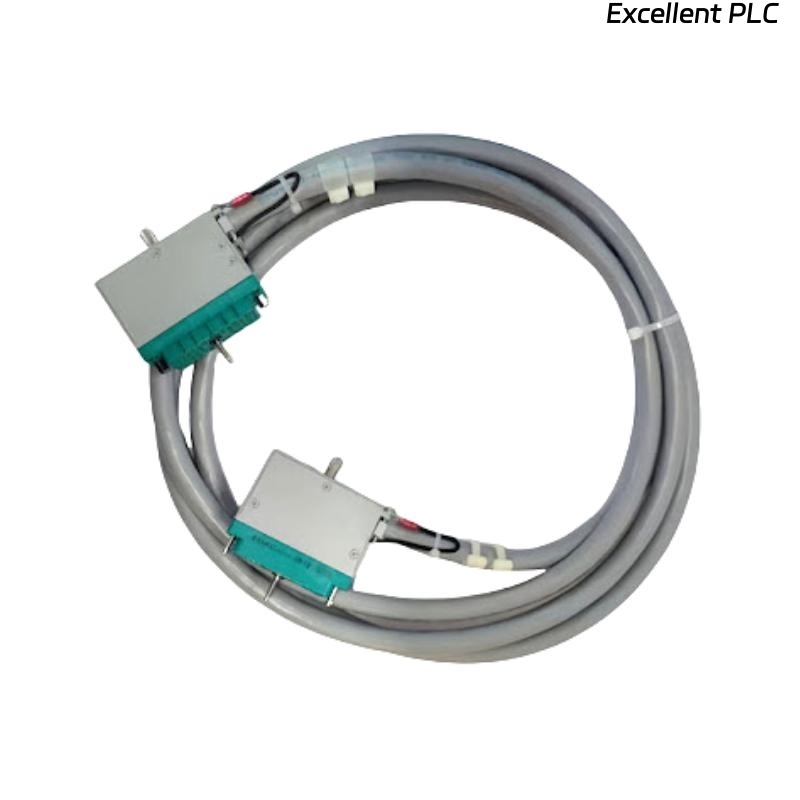

The Triconex 4000029-025 Cable Assembly is a purpose-built industrial-grade interconnection component designed for integration within Triconex safety and control systems. It plays a critical role in ensuring stable, interference-free communication between control modules, I/O devices, and associated subsystems. This assembly is manufactured to meet demanding industrial safety standards, delivering both electrical and mechanical reliability in environments where operational downtime is not an option.

With precision-engineered connectors, robust insulation, and superior shielding, the 4000029-025 ensures signal integrity even in the presence of high electromagnetic interference. It is a vital component for facilities requiring fault-tolerant control, such as oil and gas processing, petrochemical plants, and large-scale manufacturing. The design prioritizes secure connections, easy installation, and minimal maintenance requirements.

Product Parameters

| Parameter | Description |

|---|---|

| Manufacturer | Triconex (Schneider Electric) |

| Model | 4000029-025 |

| Product Type | Cable Assembly |

| Function | Secure electrical and signal connection between Triconex modules and peripheral devices |

| Connector Type | Factory-installed connectors compatible with Triconex hardware |

| Cable Shielding | Multi-layer EMI/RFI shielding |

| Operating Temperature Range | -20°C to +70°C |

| Insulation Material | High-durability industrial-grade polymer |

| Fire Resistance | Compliant with IEC and UL flame retardancy standards |

| Vibration Resistance | Designed to withstand industrial vibration levels |

| Cable Length | Optional |

| Shipping Weight | 3 kg |

| Compliance | CE, RoHS, and applicable industrial safety certifications |

Product Applications

The Triconex 4000029-025 Cable Assembly is utilized in a variety of mission-critical industrial environments, including:

-

Process Automation – Facilitates secure data transfer in refinery and chemical plant control systems.

-

Power Generation – Integral for linking safety systems in turbines, boilers, and auxiliary units.

-

Safety Instrumented Systems (SIS) – Enables fault-free safety signal communication.

-

Industrial Redundancy Architectures – Provides reliable connectivity in triple-redundant systems.

-

Manufacturing Automation – Connects PLCs, I/O modules, and process control hardware.

-

High-EMI Environments – Designed for stable performance in areas with significant electrical noise.

Product Advantages

-

High Electrical Performance – Maintains consistent signal quality for both analog and digital transmissions.

-

Robust Construction – Resistant to industrial wear, environmental stress, and vibration.

-

Full Compatibility – Seamlessly integrates with Triconex safety and control hardware.

-

Strong EMI/RFI Protection – Ensures interference-free operation in high-noise zones.

-

Ease of Maintenance – Modular design simplifies replacement and troubleshooting.

-

Long-Term Operational Reliability – Built to sustain performance over prolonged industrial use.

FAQ

1. What type of shielding does the Triconex 4000029-025 use?

It features a dual-layer shield combining foil wrap and braided copper mesh for optimal EMI and RFI protection.

2. Can this cable assembly be used with both analog and digital signals?

Yes, it is engineered to support mixed-signal transmission without performance degradation.

3. What kind of connectors are installed on this cable?

The cable comes with pre-terminated connectors specifically designed for compatibility with Triconex systems.

4. Is the cable compatible with redundant safety architectures?

Yes, it is fully suitable for use in redundant and fault-tolerant safety system designs.

5. What is the operating temperature tolerance of this cable?

It can operate reliably between -20°C and +70°C.

6. Does the cable meet global safety and environmental standards?

Yes, it is CE-marked, RoHS-compliant, and meets IEC industrial safety specifications.

7. How is signal attenuation minimized?

Low-resistance conductors and precise impedance control reduce losses during transmission.

8. Is this cable resistant to industrial chemical exposure?

Yes, the outer jacket is formulated to resist oils, solvents, and most common industrial chemicals.

9. Can it be used in high-vibration environments?

Yes, the design includes strain relief and robust construction to withstand vibration.

10. Does the cable maintain performance under electromagnetic disturbances?

Yes, the multi-layer shielding and grounding design protect against both EMI and RFI.

Recommended Related Models (Same Series or Function)

| Model | Description |

|---|---|

| 4000029-015 | Standard Cable Assembly for Triconex systems |

| 4000029-020 | Heavy-duty Cable Assembly with reinforced jacket |

| 4000029-030 | EMI-optimized Cable Assembly |

| 4000029-040 | Multi-signal Cable Assembly for expanded I/O |

| 4000029-050 | High-flex Cable Assembly for dynamic motion applications |

| 4000029-060 | Quick-connect Cable Assembly for rapid system changes |

Popular Triconex Models (Same Brand)

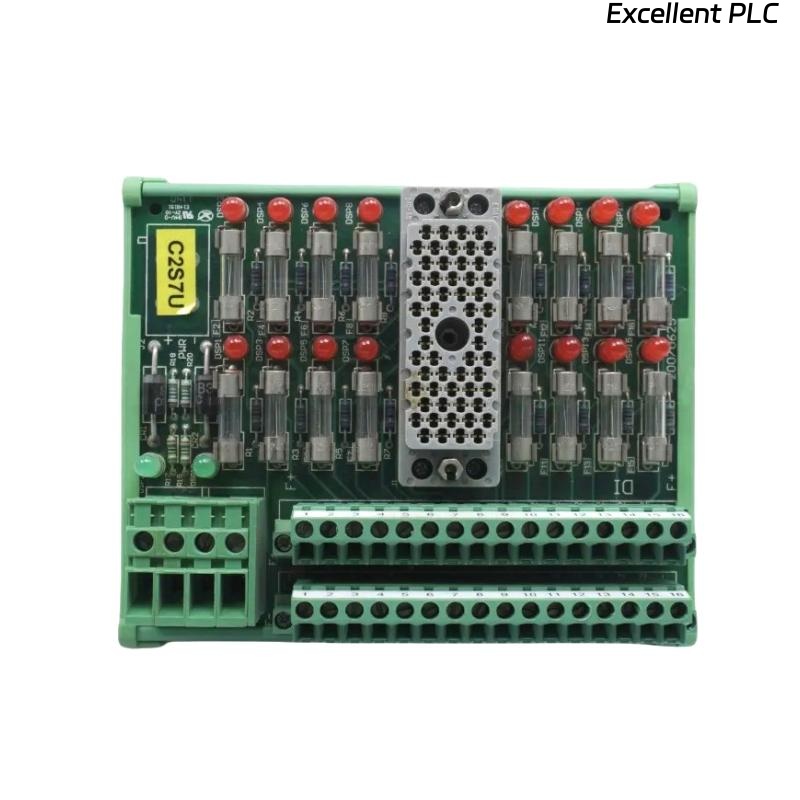

| Model | Description |

|---|---|

| 3625 | Triconex Analog Input Module |

| 3703E | Triconex Digital Input Module |

| 3503E | Triconex Main Processor Module |

| 4211 | Triconex Analog Output Module |

| 4351B | Triconex Processor Communication Module |

| 3805E | Triconex Digital Output Module |

Excellent PLC

Excellent PLC