| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

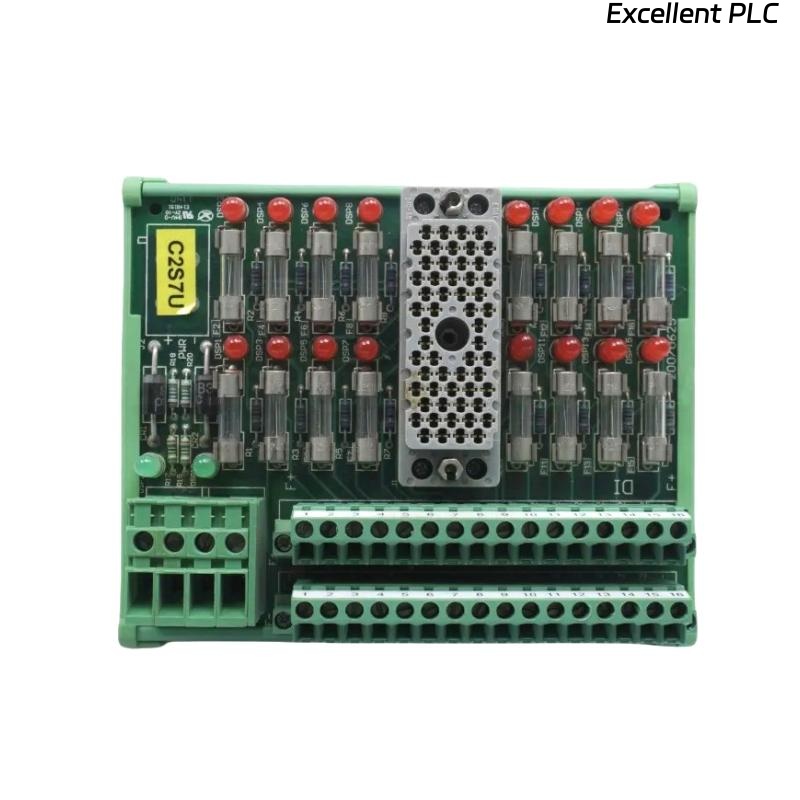

The Triconex 4211 Remote Expander Module is designed to extend the input/output capacity of the Triconex safety instrumented system (SIS) controllers. This module acts as a remote expansion unit, enabling the connection of additional I/O modules at distant locations from the main controller while maintaining the integrity and reliability of the safety system.

Manufactured to meet the high standards of industrial safety, the 4211 Remote Expander allows for flexible system architecture and scalability. It is particularly suited for applications where process control and safety require distributed I/O arrangements spread across large industrial sites. Its robust design ensures dependable operation even under harsh environmental conditions.

The module communicates seamlessly with the Triconex 4000 series controllers, providing fault-tolerant and high-availability data exchange. It plays a critical role in increasing system input/output channels without compromising system response times or safety integrity levels.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 4211 Remote Expander Module |

| Function | Remote I/O expansion for SIS |

| Communication Interface | Triconex proprietary communication |

| Supported I/O Modules | Compatible with Triconex 4300 series I/O |

| Power Supply | 24 V DC nominal |

| Operating Temperature | -40 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting | DIN rail or panel mount |

| Dimensions (W x H x D) | 250 x 160 x 30 mm |

| Weight | 6.8 kg |

| Safety Certification | SIL 3 certified |

| Standards Compliance | IEC 61508, IEC 61511 |

Product Applications

-

Oil and Gas Plants: Facilitates distributed safety control for wellheads, pipelines, and remote process units.

-

Chemical Processing: Enables safe expansion of I/O in hazardous zones spread across the plant.

-

Power Generation: Supports remote expansion in power plants for turbine, boiler, and auxiliary system monitoring.

-

Water and Wastewater Treatment: Provides remote expansion for large-scale, distributed control systems.

-

Pharmaceutical Manufacturing: Allows secure remote connection of safety I/O modules in cleanroom environments.

-

Mining and Metals: Supports safety systems spread over wide geographical areas within mining operations.

Product Advantages

-

Extended I/O Capability: Enables flexible and scalable expansion of safety system I/O across large plant areas.

-

Reliable Remote Communication: Uses Triconex proprietary protocols to maintain high integrity and fault tolerance.

-

Rugged and Durable: Designed for harsh industrial environments, capable of withstanding vibration, shock, and temperature extremes.

-

High Safety Integrity: Certified to SIL 3, ensuring compliance with international safety standards.

-

Flexible Mounting Options: Can be mounted on DIN rails or panels for ease of installation and maintenance.

-

Seamless Integration: Works flawlessly with Triconex 4000 series controllers and related modules.

-

Efficient Space Utilization: Compact size allows for installation in limited-space control cabinets.

-

Low Maintenance: Built for longevity with minimal downtime and proactive diagnostic capabilities.

-

Power Efficient: Operates on 24 V DC with optimized power consumption.

-

Enhanced Diagnostics: Provides detailed status and fault information to support predictive maintenance.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Triconex 4211 module?

It serves as a remote expander to increase I/O capacity of Triconex safety systems. -

Which I/O modules are compatible with the 4211 Remote Expander?

It supports Triconex 4300 series I/O modules. -

What is the operating temperature range for the 4211?

It operates reliably between -40 °C and +70 °C. -

How is the 4211 module powered?

The module requires a nominal 24 V DC power supply. -

Is the 4211 module certified for safety-critical environments?

Yes, it is SIL 3 certified according to IEC 61508 and IEC 61511. -

What are the physical dimensions of the module?

Dimensions are 250 x 160 x 30 mm. -

How heavy is the 4211 module?

It weighs 6.8 kg. -

Can the module be mounted on DIN rails?

Yes, it supports both DIN rail and panel mounting. -

Does the module support diagnostic capabilities?

Yes, it provides real-time status and fault monitoring. -

How does the 4211 module communicate with the main controller?

It uses Triconex proprietary communication protocols designed for high integrity and fault tolerance.

Recommended Related Models

| Model Number | Description | Key Feature |

|---|---|---|

| Triconex 4300 | Remote I/O Module | Standard distributed I/O module |

| Triconex 4200N | Remote Extender Module | Extends communication links |

| Triconex 4001 | Main Processor Module | Core processor for safety systems |

| Triconex 4010 | I/O Interface Module | Connects input/output devices |

| Triconex 4400 | Safety Relay Module | Interface for safety output relays |

| Triconex 4005 | Power Supply Module | Supplies power to safety systems |

Popular Triconex Models

| Model Number | Description | Typical Use |

|---|---|---|

| Triconex 3501 | High-performance Safety Controller | Large-scale SIS applications |

| Triconex 3100 | Compact Safety Controller | Medium-sized safety systems |

| Triconex 4000 | Modular Safety System Core | Flexible SIS platform |

| Triconex 4008 | Redundant Processor Module | High-availability processing |

| Triconex 3020 | Safety I/O Module | Versatile safety input/output |

| Triconex 4200X | Advanced Remote I/O Module | Extended remote I/O capabilities |

Excellent PLC

Excellent PLC