| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

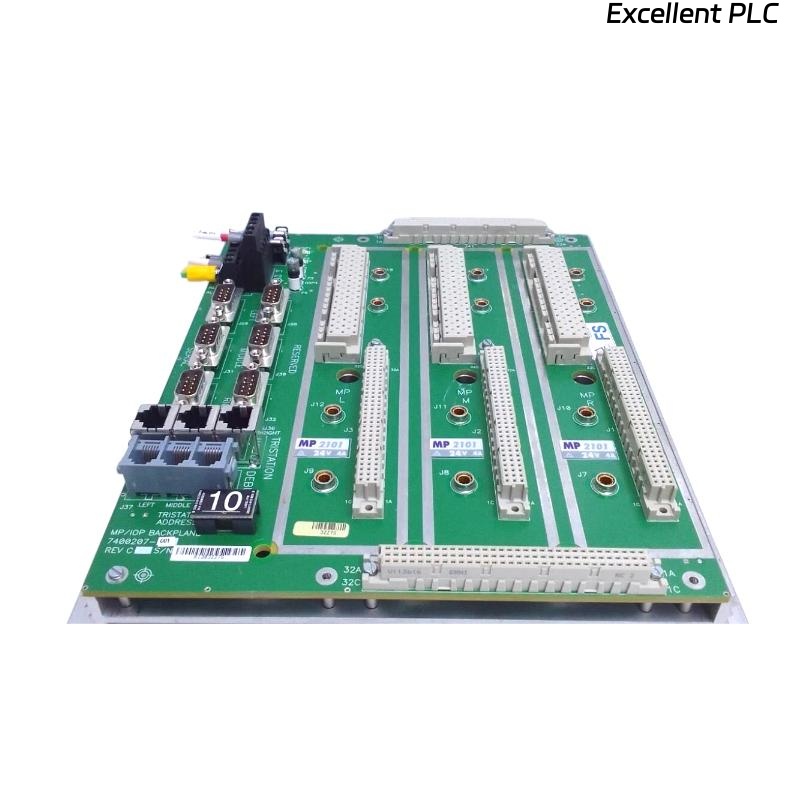

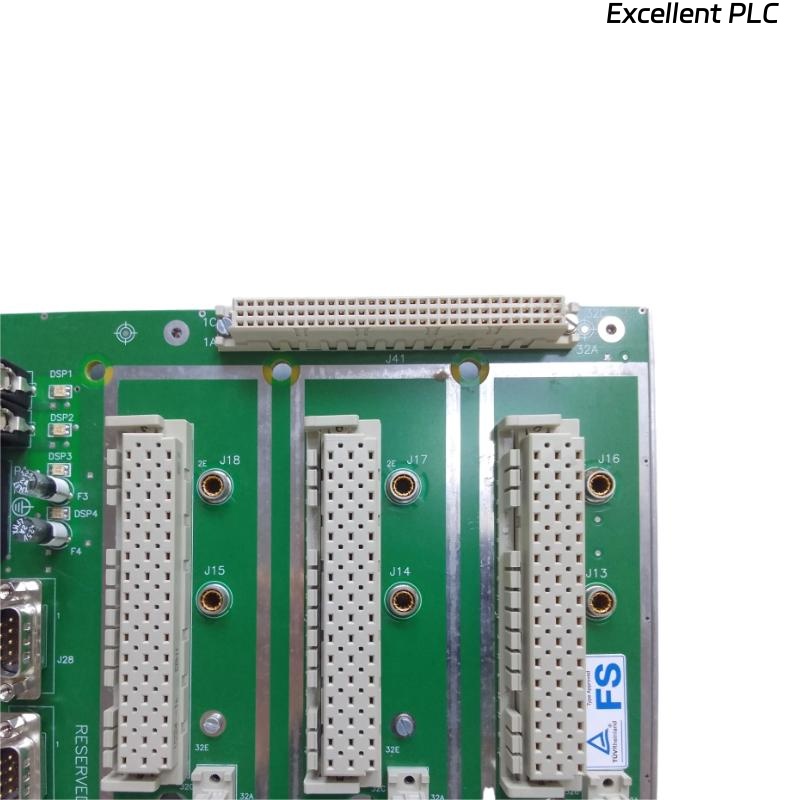

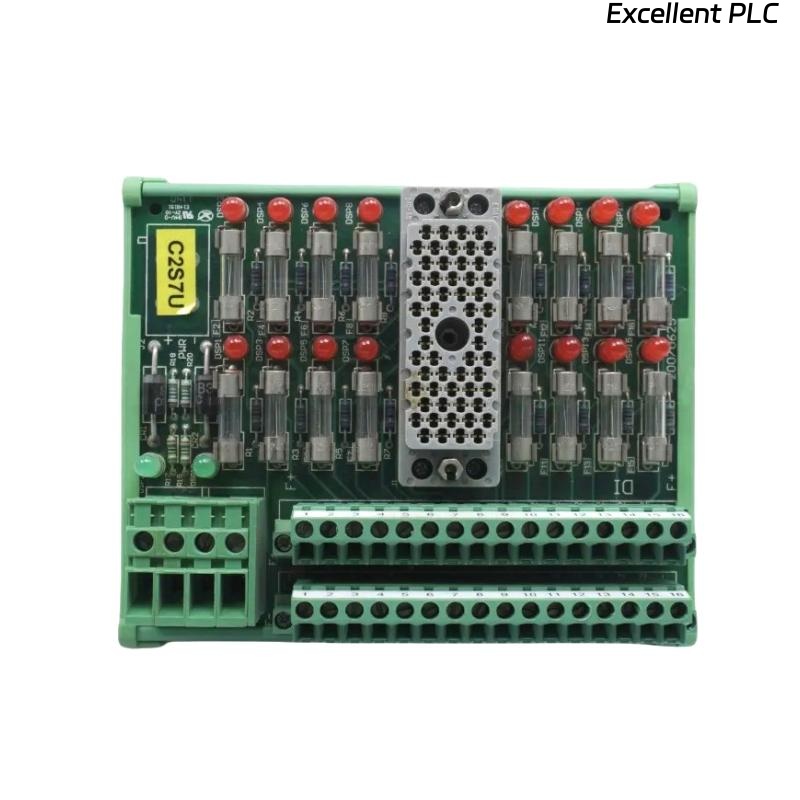

The Triconex 7400207-001 Main Processor Baseplate is a vital component within the Triconex safety instrumented system (SIS) architecture. Designed to support high-integrity applications, this baseplate serves as the physical and electrical foundation for housing the main processor module and interconnecting it with communication and I/O modules. The Triconex system, widely known for its fault-tolerant triple-modular-redundant (TMR) design, relies on the robust and reliable performance of the baseplate to maintain signal integrity, power distribution, and processor synchronization in safety-critical environments.

The 7400207-001 baseplate is engineered to support high-speed data transfer, module hot-swap, and high availability in continuous processing environments such as oil & gas, petrochemicals, nuclear, and other industries demanding rigorous safety standards. It features rugged connectors, precision-milled guide rails, and is optimized to maintain isolation, grounding, and signal fidelity.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 7400207-001 |

| Brand | Triconex |

| Product Type | Main Processor Baseplate |

| System Compatibility | Tricon, Triconex TMR System |

| Slot Configuration | Designed for Main Processor and I/O modules |

| Power Distribution | Redundant backplane power routing |

| Electrical Interface | Shielded connectors with EMI/RFI protection |

| Hot Swap Support | Yes |

| Mounting Type | Chassis/Panel mounting |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| EMC Compliance | IEC 61000, EN 50081/50082 |

| Shock & Vibration Resistance | Meets industrial automation standards |

| Dimensions (W x H x D) | 182 x 267 x 45 mm |

| Weight | 1.2 kg |

| Material | Industrial-grade metal with coating |

Product Applications

-

Emergency Shutdown Systems (ESD)

-

Fire and Gas Detection Systems (F&G)

-

Turbomachinery Control (TMC)

-

High-Integrity Pressure Protection Systems (HIPPS)

-

Burner Management Systems (BMS)

-

Nuclear and Conventional Power Plant Safety Systems

-

Offshore Platform Automation

-

Refining and Petrochemical Safety Control Systems

Product Advantages

-

Triple Modular Redundancy (TMR) Compatibility

Designed specifically for Triconex TMR architecture, ensuring high fault tolerance. -

Hot-Swappable Capability

Allows module replacement without system shutdown, enhancing uptime and maintainability. -

EMC Shielding and Industrial-Grade Connectors

Protects against electromagnetic interference and environmental disturbances. -

Rugged Construction

Suitable for use in hazardous and mission-critical environments with temperature and vibration resistance. -

Ease of Integration

Simple mechanical layout and plug-and-play compatibility reduce installation time. -

Long Lifecycle Support

Backed by Triconex’s long-term lifecycle and obsolescence support policies.

FAQ

-

What types of processor modules are supported by the 7400207-001 baseplate?

This baseplate supports Tricon main processors such as the 3009 module within the Triconex TMR system. -

Can this baseplate be used in a redundant power configuration?

Yes, it fully supports redundant power inputs and distribution across modules. -

Does the baseplate provide isolation between processor and I/O modules?

Yes, it includes isolation and grounding mechanisms to prevent signal interference. -

Is online replacement of processor modules supported?

Yes, hot-swapping is fully supported provided proper procedures are followed. -

How is synchronization between multiple processors handled?

The baseplate includes bus channels to maintain high-speed synchronization between processors. -

What kind of diagnostic features are built into the baseplate?

It supports diagnostic monitoring via the Tricon controller, including power status and module connectivity. -

Is there support for firmware upgrades via the baseplate?

Firmware is upgraded through the processor modules, but the baseplate supports the communication path for updates. -

Can it withstand harsh industrial environments like offshore rigs?

Yes, it is built to industrial standards, resistant to corrosion, vibration, and temperature extremes. -

What bus protocols does the baseplate support internally?

It supports proprietary Tricon bus architecture for real-time data exchange and control synchronization. -

Does the baseplate support redundant communications modules?

Yes, it provides slots and power for dual communication interfaces to ensure fault-tolerant communication.

Related Models from the Same Series

| Model Number | Description | Compatibility | Weight |

|---|---|---|---|

| 7400208-001 | Expansion Baseplate for Tricon | Tricon I/O & Communication | 3.0 kg |

| 7400166-390 | Main Processor Module (3009) | Tricon TMR | 2.8 kg |

| 7400206-100 | I/O Baseplate, High-Density Configuration | Tricon | 3.1 kg |

| 7400210-100 | Power Supply Baseplate | Tricon | 3.4 kg |

| 7400165-100 | Termination Panel for I/O Modules | Tricon / I/O Systems | 1.6 kg |

| 7400221-100 | Communications Baseplate | Tricon Network Interface | 2.9 kg |

Popular Triconex Models

| Model Number | Description | Application Area | Weight |

|---|---|---|---|

| 3008 | Main Processor Module | Tricon TMR System | 2.7 kg |

| 3625 | Digital Output Module | Safety Shutdown / ESD | 2.3 kg |

| 3700A | Analog Input Module | Process Measurement | 2.2 kg |

| 4000098-510 | Termination Assembly | I/O Cabling | 1.8 kg |

| 4211 | Communication Module | System Integration | 2.5 kg |

| 9662-610 | Power Supply Module | Redundant Power Systems | 3.0 kg |

Excellent PLC

Excellent PLC