| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

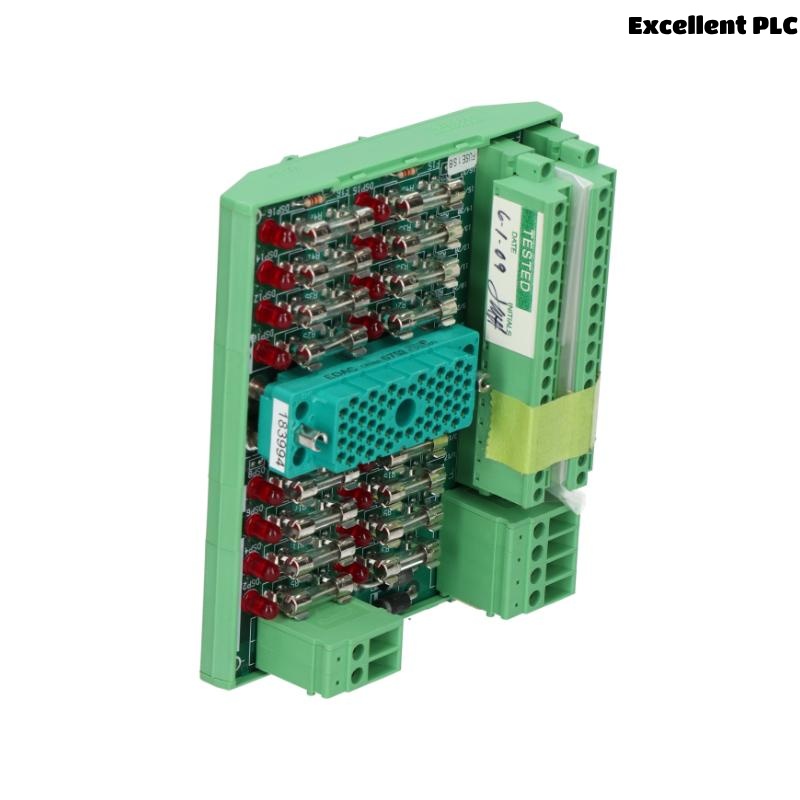

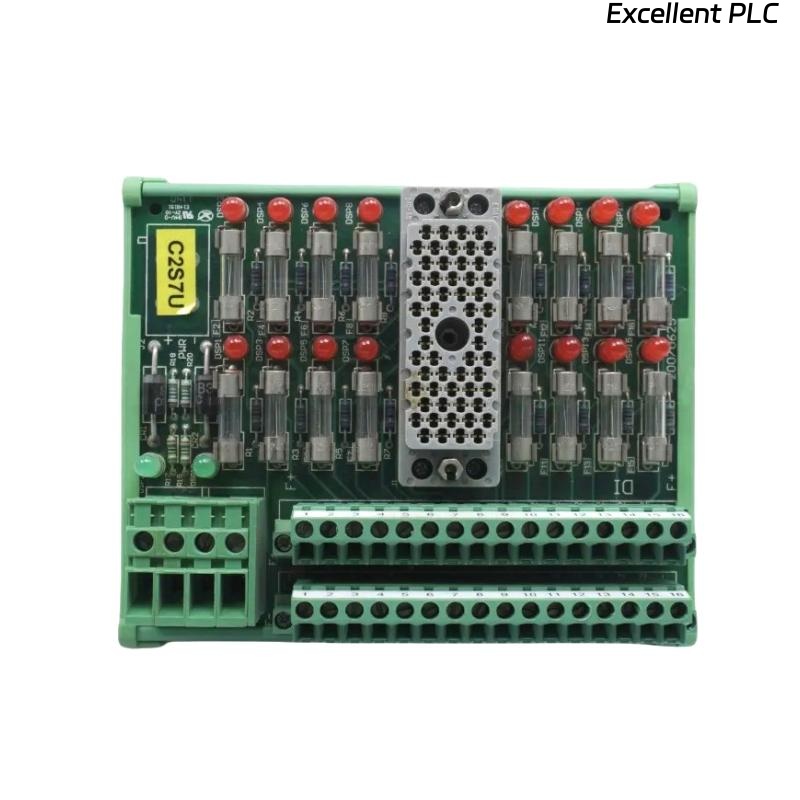

Product Introduction: Triconex 9563-610

The Triconex 9563-610 is a high-performance safety instrumented system (SIS) module designed for critical industrial automation applications. It is part of the Triconex Tricon series, renowned for its triple-modular redundancy (TMR) architecture, ensuring maximum reliability and fault tolerance. This module is widely used in oil & gas, power generation, and chemical processing industries where fail-safe operation is paramount.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | Triconex 9563-610 |

| Dimensions | 317.5 × 208.28 × 93.98 mm |

| Weight | 1 kg |

| Input Voltage | 24V DC (±10%) |

| Operating Temperature | -40°C to +70°C |

| Redundancy | Triple-Modular Redundancy (TMR) |

| Communication Protocol | Modbus, Ethernet/IP |

| Certifications | SIL 3 (IEC 61508), ATEX, UL |

| MTBF (Mean Time Between Failures) | >100,000 hours |

Product Applications

-

Oil & Gas: Used in emergency shutdown systems (ESD) for offshore platforms and refineries.

-

Power Generation: Ensures safe turbine shutdown in nuclear or thermal power plants.

-

Chemical Processing: Protects against overpressure or toxic leaks in reactors.

-

Pharmaceutical: Monitors critical batch processes to prevent contamination.

-

Mining: Safeguards heavy machinery operations in hazardous environments.

Product Advantages

-

Triple Redundancy: Three independent channels ensure continuous operation even if one fails.

-

High SIL Rating: Complies with SIL 3 standards for safety-critical systems.

-

Robust Design: Built to withstand extreme temperatures and vibrations.

-

Easy Integration: Supports industry-standard communication protocols.

-

Low Maintenance: Modular design reduces downtime for repairs.

-

Global Certifications: Approved for use in hazardous areas (ATEX, UL).

Frequently Asked Questions (FAQ)

-

What is the lifespan of the Triconex 9563-610?

The module has an MTBF of >100,000 hours and typically lasts 15+ years with proper maintenance. -

Can it operate in explosive environments?

Yes, it is ATEX-certified for Zone 1 hazardous areas. -

How does the TMR architecture work?

Three processors run in parallel, with voting logic to detect and isolate faults. -

Is firmware upgradable?

Yes, firmware can be updated via secure USB or network interfaces. -

What is the lead time for replacement units?

Standard lead time is 4-6 weeks; expedited options are available. -

Does it support wireless communication?

No, wired connections (Ethernet/IP or Modbus) are required for reliability. -

What diagnostics are available?

Built-in self-tests cover CPU, memory, and I/O health. -

Can it interface with non-Triconex systems?

Yes, via Modbus RTU/TCP or OPC UA. -

What is the power consumption?

Typically 5W under normal operation. -

Is training required for installation?

Yes, Schneider Electric offers certified training programs.

Recommended Related Models

| Model Number | Description | Key Feature |

|---|---|---|

| Triconex 9563-612 | Enhanced comms version | Dual Ethernet ports |

| Triconex 9563-615 | High-temperature variant | Operates up to 85°C |

| Triconex 9563-620 | Expanded I/O capacity | 32 digital channels |

| Triconex 9565-210 | Compact SIS controller | Space-saving design |

| Triconex 9662-810 | Advanced diagnostics module | Predictive maintenance support |

| Triconex 4351B | Legacy compatible model | Backward integration |

Popular Triconex Models

| Model Number | Description | Typical Use Case |

|---|---|---|

| Triconex Trident | Flagship TMR controller | Large-scale refinery ESD |

| Triconex 3008 | Analog input module | Process variable monitoring |

| Triconex 3625 | Digital output module | Actuator control |

| Triconex 3700E | Communication gateway | SCADA integration |

| Triconex 3805 | Power supply unit | Redundant power systems |

| Triconex 8312 | Safety historian | Event logging & analysis |

Excellent PLC

Excellent PLC