| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

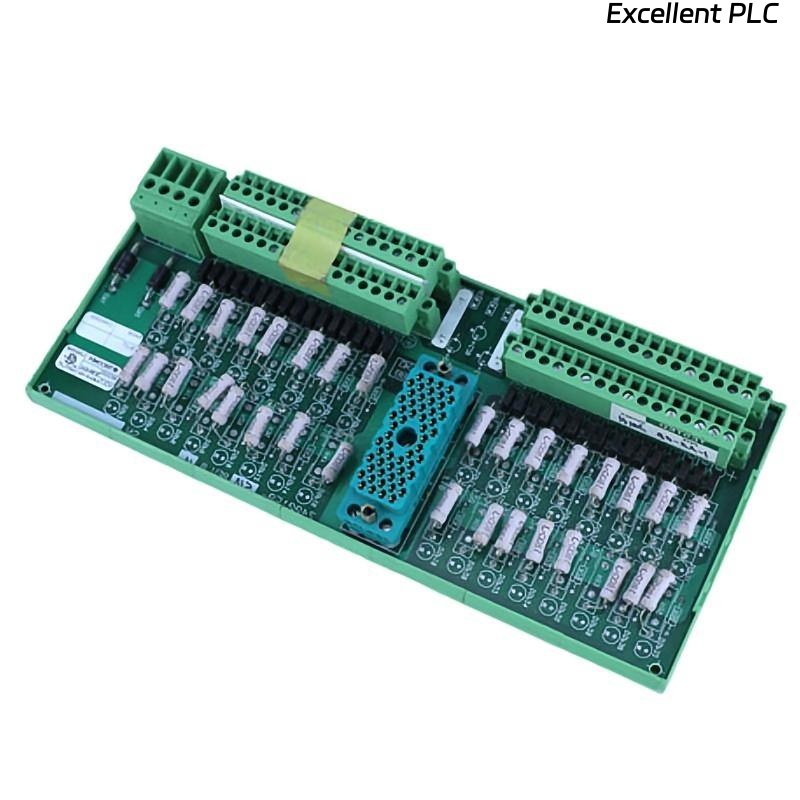

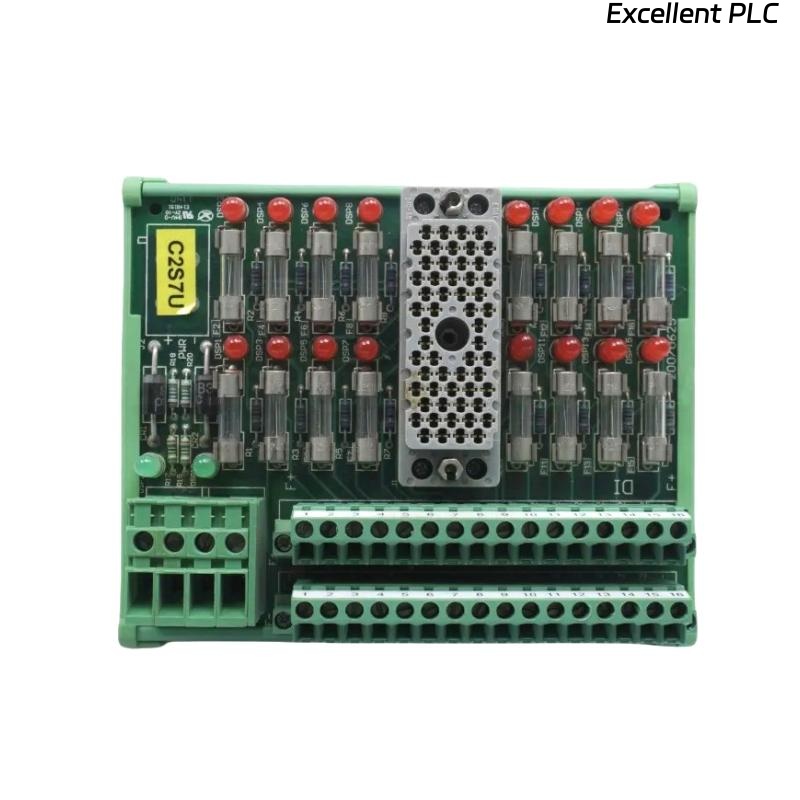

The Triconex 9760-210 Digital Input Termination Panel is a critical component in Triconex safety and process control systems, designed to interface field digital signals with the Triconex controllers. This panel provides a secure and organized termination point for digital inputs, ensuring accurate signal transmission and system integrity.

Engineered for mission-critical environments, the 9760-210 is highly reliable and capable of handling high-density digital inputs with minimal signal interference. Its robust design supports industrial automation in sectors such as petrochemical, power generation, oil & gas, and chemical processing, where safety, redundancy, and precision are paramount.

By consolidating field wiring into a well-structured interface, the panel simplifies installation, troubleshooting, and maintenance while maintaining full compliance with Triconex system architecture.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Triconex |

| Model Number | 9760-210 |

| Product Type | Digital Input Termination Panel |

| Input Channels | 32–64 (depending on configuration) |

| Signal Type | DC digital inputs, 24 VDC nominal |

| Isolation | Optical isolation between input channels |

| Response Time | <10 ms typical |

| LED Indicators | Status LEDs for each channel |

| Terminal Type | Screw terminals or plug-in connector options |

| Power Supply | Derived from Triconex backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

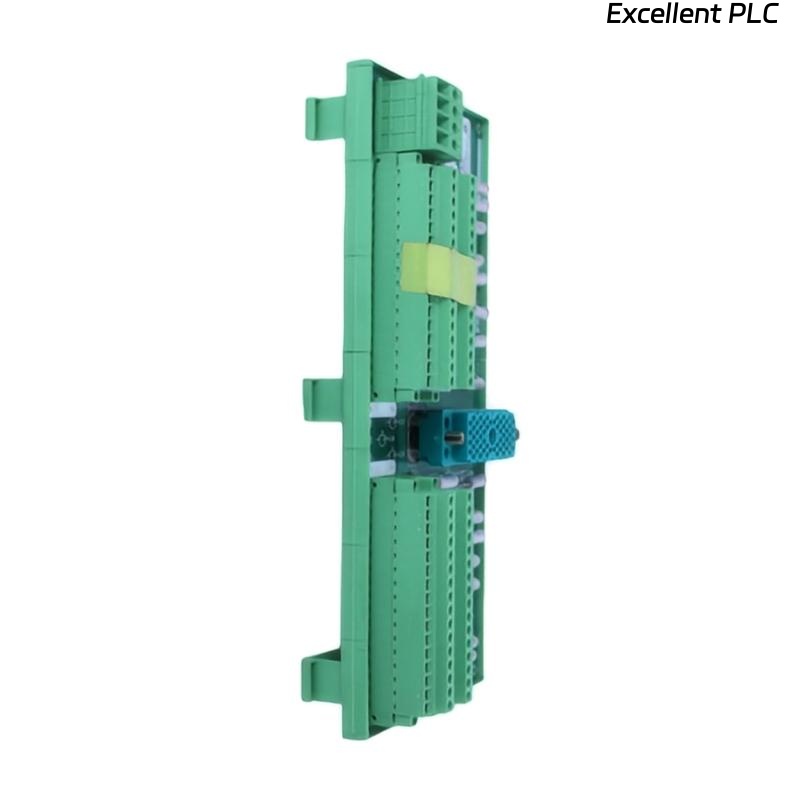

| Mounting Type | Rack-mounted or panel-mounted |

| Dimensions (W x H x D) | 76.2 ×127 × 107.95 mm |

| Weight | 0.75 kg |

| Certification | IEC 61508, SIL 2/3 capable, CE |

Product Applications

The Triconex 9760-210 Digital Input Termination Panel is widely deployed in critical industrial control and safety systems:

-

Process Safety Systems – Consolidates input signals from safety sensors and switches into Triconex safety controllers.

-

Oil & Gas Platforms – Interfaces alarms, pressure switches, flow indicators, and emergency shutdown devices.

-

Power Generation Plants – Collects status signals from turbines, generators, and auxiliary equipment.

-

Chemical and Petrochemical Plants – Ensures reliable digital input acquisition for process interlocks and safety trips.

-

Manufacturing Automation – Centralizes input wiring from discrete sensors, limit switches, and motor starters.

-

Refineries and Pipelines – Provides high-reliability signal termination for distributed field devices.

Product Advantages

-

High Reliability – Designed for continuous operation in safety-critical systems.

-

Enhanced Signal Integrity – Optical isolation reduces cross-talk and noise interference.

-

Ease of Maintenance – Organized channel layout and LED indicators facilitate quick diagnostics.

-

SIL Compliance – Supports Safety Integrity Level (SIL) 2 and 3 applications.

-

Scalable Configuration – Supports a wide range of digital input channel counts.

-

Modular Design – Compatible with standard Triconex racks for easy integration.

-

Reduced Wiring Complexity – Consolidates field wiring into a central, manageable termination panel.

FAQ

1. What digital input types does the 9760-210 support?

It supports standard 24 VDC discrete inputs, such as contact closures, proximity switches, and relay contacts.

2. How is electrical isolation achieved between channels?

Optical isolation is used to prevent interference between input signals and protect the system.

3. Can the panel be hot-swapped in a running system?

No, the panel must be powered down before installation or removal to prevent potential faults.

4. What is the response time for digital input signals?

Typical response time is under 10 milliseconds, ensuring fast detection and reporting to the controller.

5. Are there diagnostic indicators for each input channel?

Yes, each channel has an LED status indicator to quickly identify active or faulty inputs.

6. Can the panel support redundant Triconex configurations?

Yes, it is fully compatible with Triconex redundant and safety-critical system architectures.

7. What is the maximum number of input channels supported per panel?

Depending on configuration, the panel can support between 32 and 64 digital input channels.

8. How is the module mounted in a Triconex system?

It is designed for rack or panel mounting within Triconex cabinets.

9. Is the 9760-210 compliant with functional safety standards?

Yes, it meets IEC 61508 and supports SIL 2 and SIL 3 applications.

10. Can the panel be configured for different input voltage levels?

It is designed primarily for 24 VDC inputs; other voltage levels require signal conditioning or interface modules.

Recommended Related Models (Same Series)

| Model Number | Description |

|---|---|

| 9760-200 | Digital Input Termination Panel, smaller channel count |

| 9760-220 | Digital Output Termination Panel |

| 9760-230 | Analog Input Termination Panel |

| 9760-240 | Analog Output Termination Panel |

| 9760-250 | Relay Output Termination Panel |

| 9760-260 | Mixed I/O Termination Panel |

Popular Triconex Models (Same Brand)

| Model Number | Description |

|---|---|

| 3508 | Triconex Safety Controller CPU |

| 3507 | Triconex Safety Controller Power Supply |

| 3750 | Triconex Redundant Control Processor |

| 9770 | Triconex Network Communication Module |

| 9760-210 | Digital Input Termination Panel |

| 9760-220 | Digital Output Termination Panel |

Excellent PLC

Excellent PLC