| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

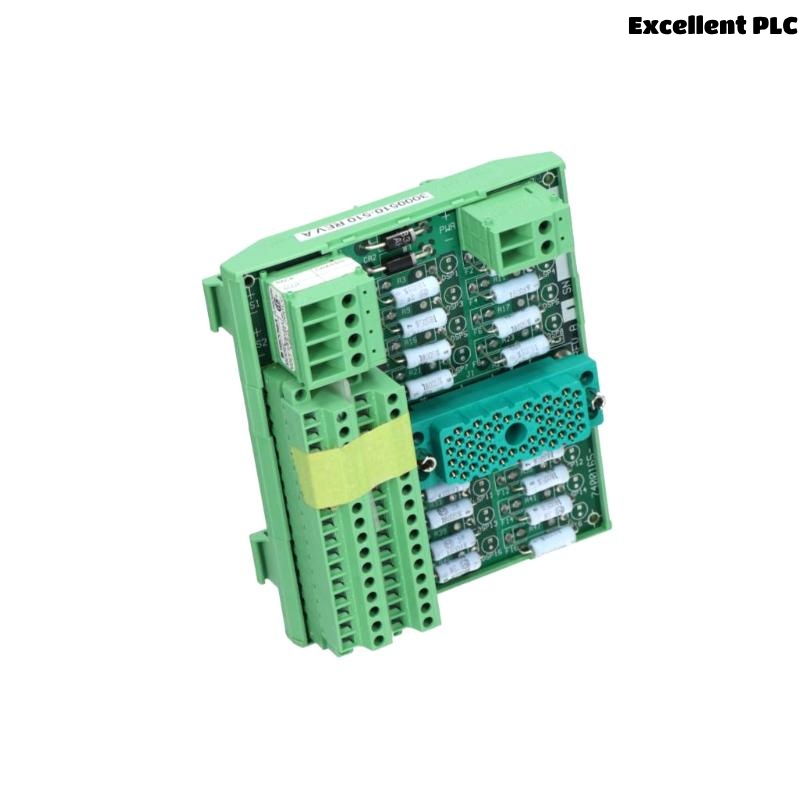

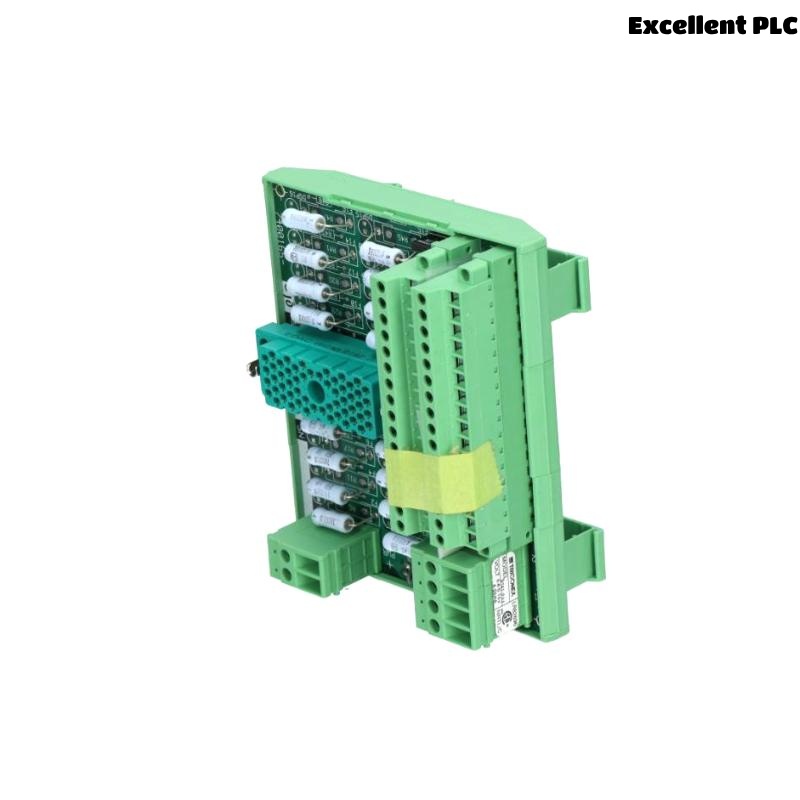

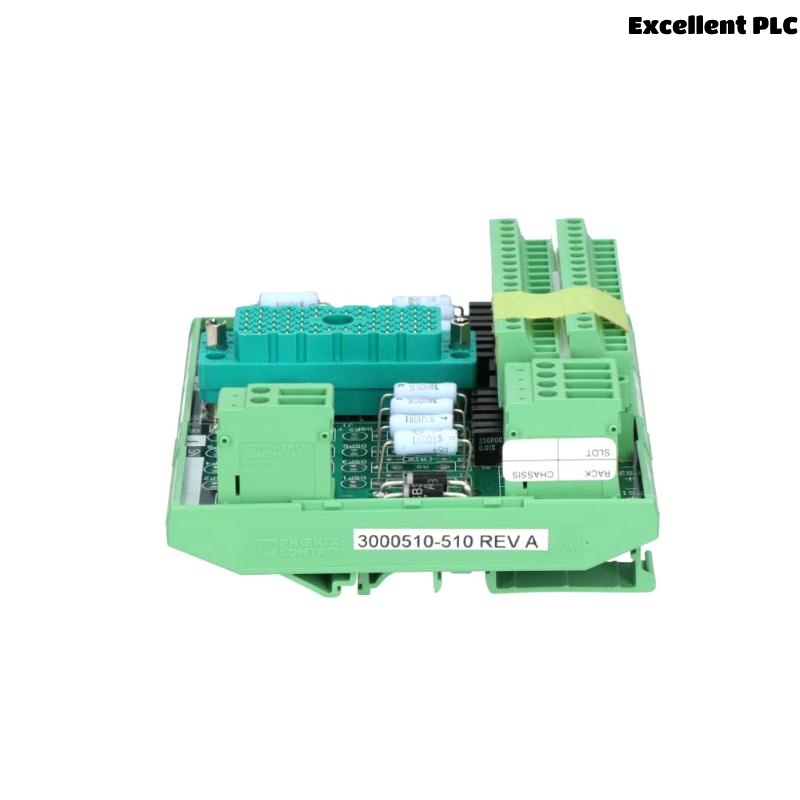

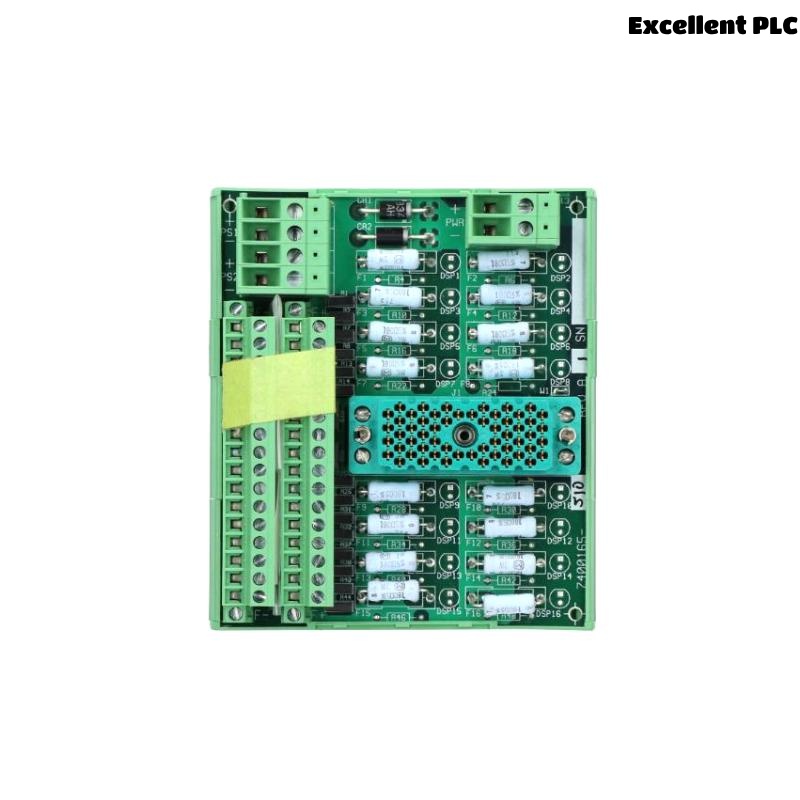

The Triconex 9761-210 Terminal Panel Module (Part Number: 3000510-510) is a dedicated terminal wiring interface designed to seamlessly integrate with Triconex Tricon™ safety systems. As part of the critical infrastructure in safety instrumented systems (SIS), this module facilitates reliable and orderly connection of I/O signals from field instruments to the system’s logic solvers.

The terminal panel ensures ease of maintenance, clean wire management, and high noise immunity. It is engineered to meet the demanding requirements of hazardous and mission-critical industries where safety, accuracy, and fault tolerance are paramount.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Terminal Panel Module |

| Model Number | 9761-210 |

| Part Number | 3000510-510 |

| Function | I/O Field Wiring Interface Terminal Panel |

| System Compatibility | Triconex Tricon™ Safety Systems |

| Supported I/O | Typically used for Analog/Digital I/O Termination |

| Terminal Type | Screw-Type Terminal Blocks |

| Channel Capacity | Up to 32 signal channels |

| Mounting Type | Panel Mount |

| Material | Industrial-grade FR4 PCB + rugged terminal base |

| Voltage Isolation | ≥1500 Vrms |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Shock & Vibration | Complies with IEC 60068-2 standards |

| Certifications | CE, UL, FM, CSA, RoHS |

| Dimensions (W × H × D) | 114.3 ×127 × 107.95 mm |

| Weight | 0.85 kg |

| Mounting Accessories | Supplied with screws and wiring guide |

| Connection to System | Ribbon cable or shielded field wiring harness |

Product Applications

The Triconex 9761-210 module plays an integral role in the functioning of high-reliability process systems, including:

-

Oil & Gas Exploration and Refining – Providing safe and redundant field signal connectivity in offshore platforms and refineries.

-

Petrochemical Plants – Secure termination of analog and digital I/O for reactors and distillation columns.

-

Nuclear Energy Plants – Ensuring reliable and noise-isolated wiring for sensors and actuators in safety zones.

-

Power Generation Facilities – Monitoring turbine parameters and facilitating fault-tolerant system wiring.

-

Water and Wastewater Treatment – Connecting field instrumentation for pressure, flow, and level control.

-

Pharmaceutical Manufacturing – Ensuring GMP-compliant safety and process interlocks.

Product Advantages

-

Field-Wiring Convenience: Clean layout simplifies installation and wire identification.

-

TMR System Integration: Fully compatible with Triconex Triple Modular Redundant (TMR) architecture.

-

High Durability: Resistant to environmental hazards including dust, heat, and moisture.

-

Safe and Isolated Wiring: Enhanced dielectric protection between channels and grounding.

-

Fast Maintenance: Terminal labels and group separation allow for quick troubleshooting.

-

Industrial Grade Build: Built to last in mission-critical safety environments.

Frequently Asked Questions (FAQ)

-

What type of systems can use the 9761-210 Terminal Panel?

This panel is intended for use with Triconex Tricon™ safety systems and associated I/O modules. -

Is the panel suitable for analog or digital signals?

It supports both analog and digital signal termination depending on system configuration. -

Can it be mounted in hazardous areas?

The panel itself should be mounted in a control cabinet, but it supports signals from hazardous-rated field devices. -

What kind of terminal blocks are used?

It uses industrial-grade screw terminals to ensure secure field wiring. -

Does it come pre-wired?

No, field wiring must be connected during installation, but wire labeling aids the process. -

What is the maximum number of channels?

Typically supports up to 32 signal channels per unit, depending on I/O layout. -

Is there electrical isolation between signal lines?

Yes, the panel offers dielectric strength ≥1500 Vrms to isolate signals and avoid cross-talk. -

How do I connect this panel to the I/O chassis?

You can use Triconex-specified ribbon cables or standard shielded harnesses. -

Is the documentation available from Triconex?

Yes, detailed wiring diagrams and technical manuals are available via Schneider Electric. -

How does this panel improve system reliability?

It ensures clean, noise-immune, and organized field wiring which is critical in safety instrumented systems.

Related Models (Same Series or Function)

| Model Number | Description | Application |

|---|---|---|

| 9761-210B | Terminal Panel with Extended Mount Bracket | Same as 9761-210 with mounting flexibility |

| 9760-210 | Analog Input Terminal Panel | For analog input wiring |

| 9762-300 | Relay Output Terminal Panel | For digital output/relay connectivity |

| 9761-310 | High-Density Terminal Panel | For compact control cabinets |

| 9765-210 | 24VDC Digital Input Terminal Panel | For low-voltage field inputs |

| 9761-250 | Shielded Terminal Panel with Ground Rail | Enhanced EMI protection |

Popular Triconex Models (Same Brand)

| Model Number | Function | Key Feature |

|---|---|---|

| 3008 | Main Processor Module | Core logic controller for TMR systems |

| 3721 | Analog Input Module | High-speed AI acquisition |

| 3625 | Digital Output Module | Rugged fault-tolerant output channels |

| 4211 | Communication Interface Module | Modbus and other protocol support |

| 3501E | I/O Chassis Expansion Module | High-capacity I/O expansion |

| 4351B | Enhanced Main Processor | Advanced processing with fast I/O scan rates |

Excellent PLC

Excellent PLC