| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

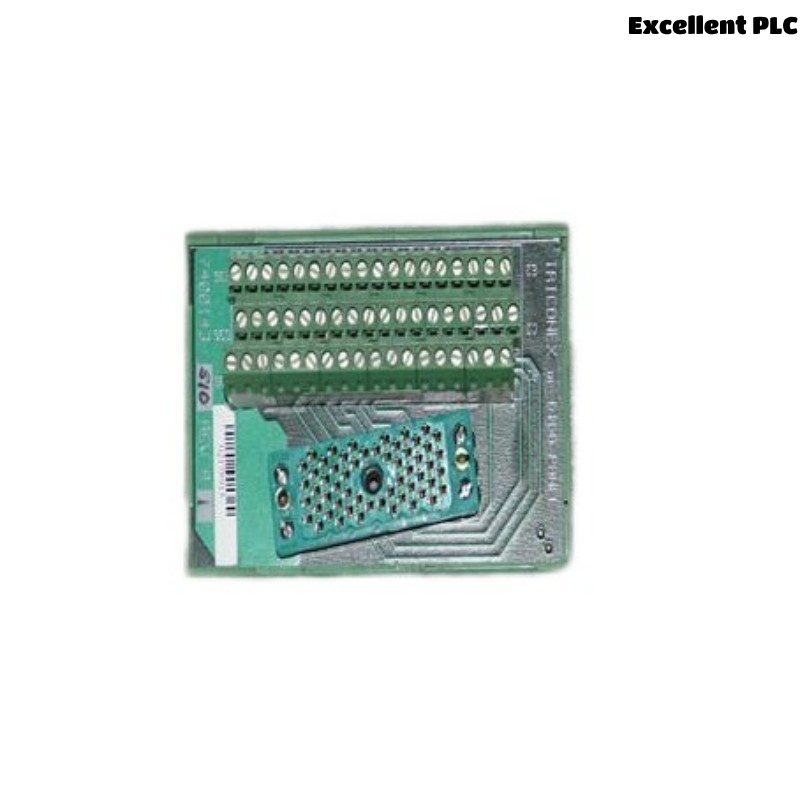

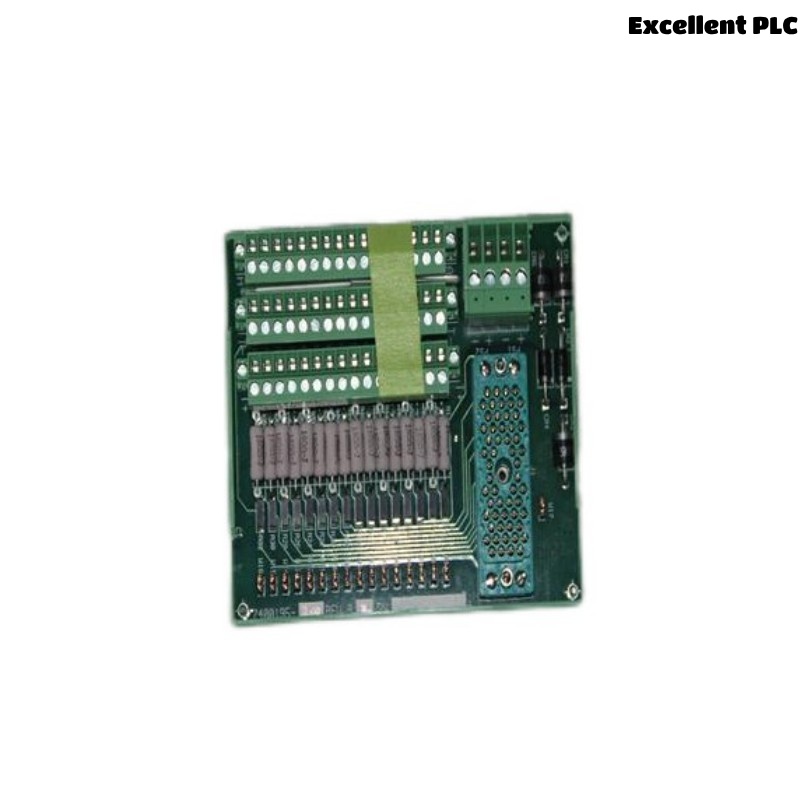

Triconex 9771-220 Overview

The Triconex 9771-220 is a part of the Triconex series, known for providing high-reliability and safety in industrial automation systems. It is an advanced Safety Instrumented System (SIS), designed for critical control applications. The 9771-220 is optimized for use in safety-critical processes where downtime can result in significant operational, environmental, or safety risks.

Built with industry-leading fault-tolerant technologies, the Triconex 9771-220 ensures that processes are continuously monitored and controlled with a focus on safety and efficiency. It supports redundant and fail-safe operation, making it an ideal solution for industries requiring the highest levels of process safety.

Triconex 9771-220 Specifications

| Parameter | Value |

|---|---|

| Model | Triconex 9771-220 |

| Dimension | 114.3 × 145.52 × 107.95 mm |

| Weight | 0.9 kg |

| Operating Voltage | 24 V DC |

| Input/Output Points | 16 Digital Inputs, 16 Digital Outputs |

| Temperature Range | -40°C to +70°C |

| Power Consumption | 5W |

| Certification | SIL 3 Certified |

| Communication Protocol | Modbus, Profibus, Ethernet |

| Enclosure Rating | IP20 |

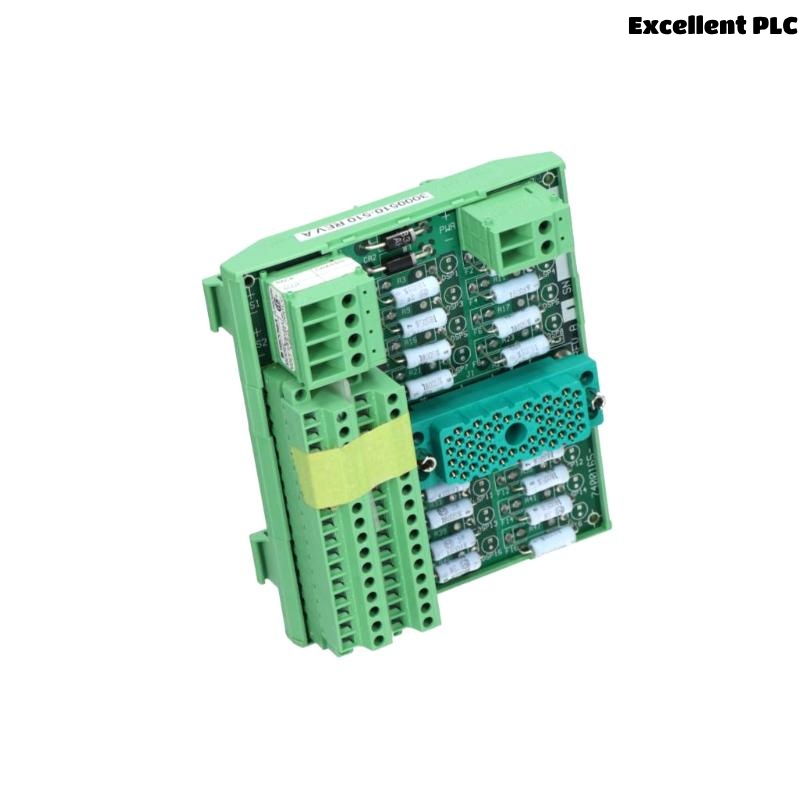

| Mounting Type | DIN Rail |

Triconex 9771-220 Applications

The Triconex 9771-220 is widely used in various industries requiring high levels of operational safety, including:

-

Oil & Gas: For control and monitoring of critical equipment such as drilling rigs, pipelines, and refineries.

-

Chemical & Petrochemical: To ensure safe and efficient operation of chemical reactors, boilers, and other hazardous equipment.

-

Power Generation: Used in critical systems within power plants to maintain safe operations.

-

Industrial Automation: Ideal for control systems that require fail-safe monitoring and process integrity.

-

Water Treatment: Ensures safe and reliable monitoring of treatment plants and pumping stations.

Advantages of Triconex 9771-220

-

High Availability and Reliability: The Triconex 9771-220 is designed with redundant channels and fault-tolerant architecture, ensuring continuous operation even in the event of component failure.

-

SIL 3 Certified: This product is certified for Safety Integrity Level (SIL) 3, meeting the highest safety standards for critical control applications.

-

Wide Temperature Range: The device is operational in extreme environments, with an operating temperature range from -40°C to +70°C, making it suitable for challenging industrial settings.

-

Ease of Integration: It supports multiple communication protocols like Modbus, Profibus, and Ethernet, allowing it to be easily integrated with existing control systems.

-

Compact Design: With a compact form factor and DIN rail mounting, the 9771-220 is easy to install and saves space in control panels.

-

Maintenance-Free: Designed for longevity, the Triconex 9771-220 requires minimal maintenance, reducing operational downtime and costs.

-

Enhanced Safety Features: It provides reliable monitoring of safety-critical processes and has built-in features for fault detection, ensuring high system safety.

Frequently Asked Questions (FAQs)

Q1: What industries can use the Triconex 9771-220?

A1: The Triconex 9771-220 is used in industries like oil and gas, chemical processing, power generation, water treatment, and industrial automation. It is ideal for critical systems requiring safety integrity.

Q2: Is the Triconex 9771-220 easy to install?

A2: Yes, the Triconex 9771-220 has a DIN rail mounting system that makes installation quick and easy, even in tight spaces.

Q3: What is the power consumption of the Triconex 9771-220?

A3: The power consumption of the Triconex 9771-220 is approximately 5W.

Q4: Can I integrate the Triconex 9771-220 with existing control systems?

A4: Yes, it supports communication protocols like Modbus, Profibus, and Ethernet, making it easy to integrate with most control systems.

Q5: What is the operating voltage range for the Triconex 9771-220?

A5: The operating voltage for the Triconex 9771-220 is 24 V DC.

Q6: Does the Triconex 9771-220 have certifications?

A6: Yes, the Triconex 9771-220 is SIL 3 certified, meeting high safety standards for critical control applications.

Q7: What is the temperature range of the Triconex 9771-220?

A7: The operating temperature range is -40°C to +70°C, allowing it to function in extreme environments.

Q8: What type of outputs does the Triconex 9771-220 support?

A8: The Triconex 9771-220 supports 16 digital inputs and 16 digital outputs for versatile monitoring and control.

Q9: What is the weight of the Triconex 9771-220?

A9: The Triconex 9771-220 weighs approximately 2.5 kg.

Q10: Is the Triconex 9771-220 suitable for outdoor applications?

A10: While it is suitable for many industrial environments, the Triconex 9771-220 has an IP20 enclosure rating, meaning it is designed for indoor use only.

Recommended Models (Same Series/Related)

| Model | Description | Key Parameter |

|---|---|---|

| Triconex 9801-221 | High-availability safety system | SIL 3, Redundant Inputs |

| Triconex 9400-201 | Safety controller for critical systems | 16 Digital Inputs/Outputs |

| Triconex 9001-110 | Industrial automation controller | Modbus Communication |

| Triconex 9200-115 | Process safety monitoring system | Supports Profibus |

| Triconex 9300-120 | Fail-safe control for hazardous processes | Compact and Reliable |

| Triconex 9100-210 | Modular control and safety system | Flexible Inputs/Outputs |

Popular Triconex Models

| Model | Description | Key Parameter |

|---|---|---|

| Triconex 9000-101 | High-performance safety controller | SIL 3 Certified |

| Triconex 9070-220 | Advanced fault detection system | 24 V DC Operating Voltage |

| Triconex 9100-115 | Process safety for automation | Easy Integration |

| Triconex 9071-110 | Safety and fault tolerance for control | Modular Design |

| Triconex 9000-105 | Critical infrastructure safety | Long-Lasting Design |

| Triconex 9500-120 | Automation and safety for power generation | Industrial Reliability |

Excellent PLC

Excellent PLC