| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

![]()

Introduction

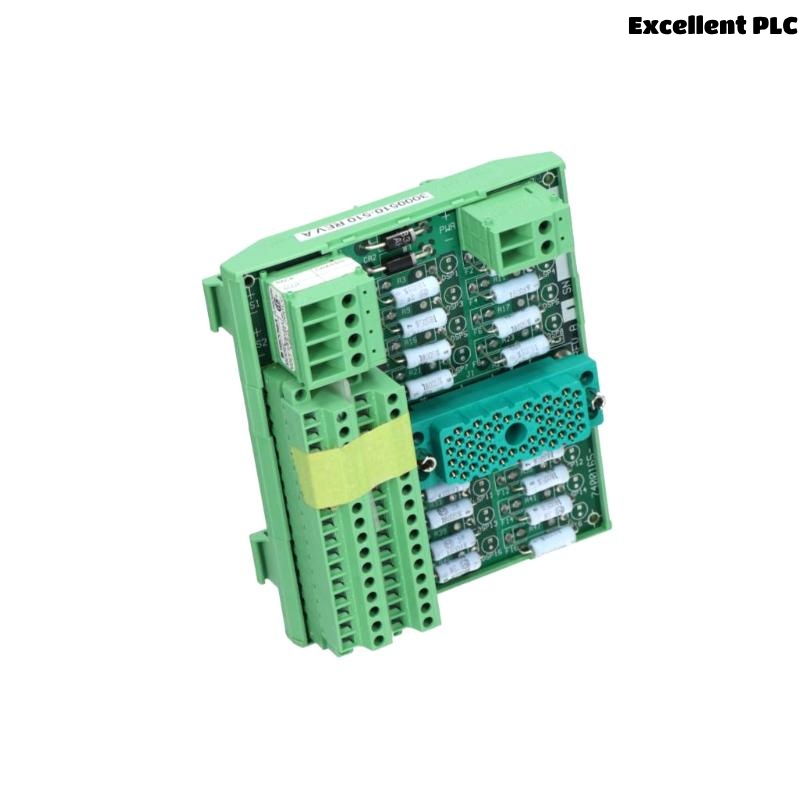

The Triconex 9802 is a high-performance, versatile, and reliable safety system designed for use in critical industrial applications. It is part of the Triconex family, known for its advanced fault-tolerant technology, providing continuous safety and control. This product is primarily used in process automation and safety critical systems where high availability and safety integrity are paramount. It is used in various industries including petrochemical, oil and gas, power generation, and chemical manufacturing, offering unmatched operational reliability and ease of integration.

Product Features

-

High Availability: Triconex 9802 offers advanced fault tolerance with Triple Modular Redundancy (TMR) ensuring 99.9999% system uptime.

-

Scalability: The product can be easily scaled to meet the specific needs of the application, from small systems to large, complex control and safety systems.

-

Flexible I/O Options: Compatible with a wide range of I/O modules for flexibility in configuration.

-

Comprehensive Diagnostics: Features advanced diagnostics capabilities to support proactive maintenance and reduce downtime.

-

SIL 3 Certification: Meets stringent Safety Integrity Level (SIL 3) requirements, ensuring compliance with industry safety standards.

-

Seamless Integration: Supports seamless integration with other control and safety systems, simplifying system design and deployment.

-

Remote Monitoring: Includes built-in communication protocols for remote monitoring and control.

-

Redundancy: Fully redundant design ensures continued operation even in case of hardware failure.

Product Specifications

| Parameter | Value |

|---|---|

| Model | Triconex 9802 |

| Dimensions | 132 x 205 x 48 mm |

| Weight | 2.267 kg |

| Power Supply | 24 VDC |

| Temperature Range | -20°C to +60°C |

| Operating Humidity | 5% to 95% (Non-condensing) |

| Communication Protocols | Modbus, Profibus, Ethernet |

| Certification | SIL 3, IEC 61508, IEC 61511 |

Applications

The Triconex 9802 is widely used in industries requiring high safety and reliability, such as:

-

Petrochemical & Chemical Plants: Ensures safe operation of critical equipment like reactors, distillation columns, and tanks.

-

Oil & Gas Industry: Critical for managing wellhead control systems and emergency shutdown systems (ESD).

-

Power Generation: Used for turbine protection, boiler control, and grid safety.

-

Pharmaceuticals: Provides automated and secure control for pharmaceutical production environments.

-

Transportation: Used in railway control systems, offering safety-critical controls for signaling and track switching.

Advantages

-

Reliability: Triconex 9802 is built to be highly reliable, with features like fault tolerance and redundancy ensuring system integrity at all times.

-

Safety Assurance: With SIL 3 certification, the product guarantees the highest level of safety for mission-critical applications.

-

Cost Efficiency: Reduces the cost of operations by preventing system failures and minimizing downtime.

-

Flexible Integration: Offers a wide range of communication protocols that support easy integration with existing systems.

-

Advanced Diagnostics: Built-in diagnostics tools allow for real-time monitoring and troubleshooting, helping prevent costly failures.

FAQ

-

Q: What industries can use the Triconex 9802?

A: It is ideal for industries such as oil and gas, petrochemical, power generation, pharmaceuticals, and chemical plants. -

Q: What certifications does the Triconex 9802 have?

A: It is certified to SIL 3, IEC 61508, and IEC 61511, ensuring it meets the highest safety standards. -

Q: How does the Triconex 9802 ensure system redundancy?

A: The product uses Triple Modular Redundancy (TMR), which ensures continued operation even in case of component failures. -

Q: What is the power requirement for the Triconex 9802?

A: The unit requires a 24 VDC power supply. -

Q: How can the Triconex 9802 be integrated with other systems?

A: It supports communication protocols like Modbus, Profibus, and Ethernet for seamless integration with existing systems. -

Q: What is the operating temperature range for the Triconex 9802?

A: The operating temperature range is -20°C to +60°C. -

Q: Can the Triconex 9802 be used in hazardous environments?

A: Yes, the product is designed for use in hazardous environments where high reliability and safety are critical. -

Q: What diagnostic capabilities does the Triconex 9802 offer?

A: It includes advanced diagnostic features for real-time monitoring, reducing downtime and increasing system reliability. -

Q: How easy is it to scale the Triconex 9802 system?

A: The system is highly scalable and can be configured for small or large systems, depending on the application needs. -

Q: Is remote monitoring available with the Triconex 9802?

A: Yes, the system supports remote monitoring and control through standard communication protocols.

Recommended Models (Same Series / Related)

| Model | Description | Key Features |

|---|---|---|

| Triconex 9801 | Entry-level Triconex safety system | SIL 3, modular I/O system |

| Triconex 9803 | Advanced system with enhanced diagnostics | Fault-tolerant, remote control |

| Triconex 9804 | High-capacity version for large installations | High redundancy, scalable |

| Triconex 9805 | Compact solution for small applications | Flexible, easy to integrate |

| Triconex 9901 | For complex safety and control systems | SIL 3, comprehensive I/O |

| Triconex 9902 | Enhanced communication and diagnostics | High performance, reliability |

Popular Models from Triconex

| Model | Description | Key Features |

|---|---|---|

| Triconex 9802 | High-reliability safety system | Triple Modular Redundancy, SIL 3 |

| Triconex 9700 | Advanced safety and control system | Flexible I/O, diagnostics tools |

| Triconex 8900 | Modular system for critical processes | Scalable, fault-tolerant |

| Triconex 9903 | Advanced system for large-scale plants | High availability, SIL 3 |

| Triconex 9120 | System for complex control systems | Flexible integration, diagnostics |

| Triconex 7800 | Entry-level safety system | Reliable, easy to integrate |

Excellent PLC

Excellent PLC