| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

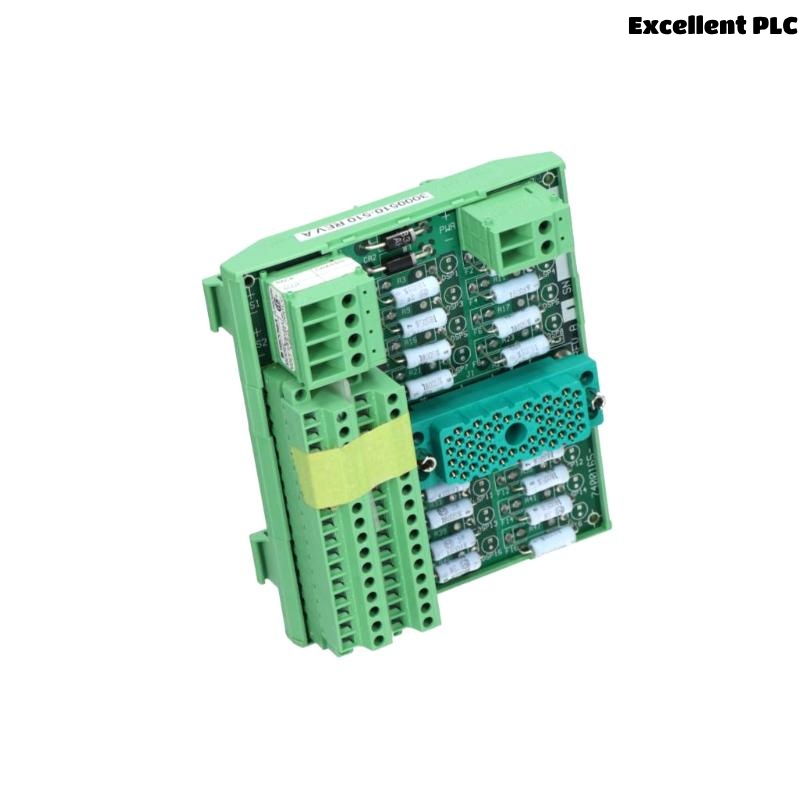

Triconex 9853-610 Overview

The Triconex 9853-610 is a highly reliable and robust safety system designed for critical process control in industrial settings. This model is part of the Triconex safety systems, offering superior fault tolerance, redundancy, and real-time processing to ensure the safety and reliability of operations. Triconex, known for its industry-leading safety solutions, offers this model to help minimize downtime and prevent catastrophic failures in industries such as oil and gas, petrochemical, and power generation.

With its advanced diagnostics and maintenance features, the Triconex 9853-610 delivers high performance and ensures the protection of both personnel and equipment. The unit’s ability to operate in harsh conditions makes it ideal for a wide range of applications where safety is paramount.

Product Features

-

Redundancy and Fault Tolerance: Equipped with hot backup functionality to provide continuous operations even in case of hardware failure.

-

Real-Time Monitoring: Provides real-time status updates and diagnostics, enhancing operational visibility.

-

Advanced Diagnostics: Built-in diagnostics for easier troubleshooting and maintenance.

-

Safety Integrity: Meets SIL3 standards for functional safety.

-

Wide Temperature Range: Operates effectively in extreme environments.

-

Compatibility: Fully compatible with other Triconex products and third-party equipment for seamless integration.

Technical Specifications

Below are the technical specifications of the Triconex 9853-610:

| Specification | Details |

|---|---|

| Model | Triconex 9853-610 |

| Type | Safety System Controller |

| Dimensions | 150 x 118 x 83 mm |

| Weight | 0.4 kg |

| Voltage | 24V DC |

| Power Consumption | 10W |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95%, Non-condensing |

| Mounting | DIN Rail Mount |

| Communication Protocol | Modbus, Profibus, Ethernet |

| Certifications | SIL3, IEC 61508, IEC 61511, UL, CE |

Applications

The Triconex 9853-610 is used across various industrial sectors for critical safety applications. Some of the key applications include:

-

Oil and Gas Industry: For safety systems that protect operations such as drilling, refining, and transportation.

-

Power Generation: Ensures the safe operation of nuclear, fossil, and renewable energy plants.

-

Chemical and Petrochemical Plants: Controls safety systems to prevent hazardous chemical releases.

-

Manufacturing: For ensuring the safety of automated processes, including assembly lines and production facilities.

Advantages

-

High Reliability: Designed for high availability with redundant components and fault-tolerant design.

-

Ease of Integration: Compatible with other Triconex systems and a wide range of third-party equipment.

-

Simplified Maintenance: The built-in diagnostics and status monitoring reduce maintenance efforts and downtime.

-

Cost-Effective: By reducing the risk of system failures and improving uptime, this model helps to lower operational costs.

-

Compliance with Safety Standards: Fully compliant with international safety standards, ensuring the safety of personnel and equipment.

Frequently Asked Questions (FAQs)

1. What is the main application of the Triconex 9853-610?

The Triconex 9853-610 is primarily used in safety-critical environments where reliability is essential, including industries like oil & gas, power generation, and chemical plants.

2. How does this product handle faults or failures?

It features redundancy and fault tolerance mechanisms that allow continuous operation even if one component fails.

3. What certifications does the Triconex 9853-610 hold?

This product is certified for SIL3 safety integrity, in compliance with IEC 61508 and IEC 61511 standards.

4. Can the Triconex 9853-610 be integrated into existing systems?

Yes, it is fully compatible with other Triconex systems and supports protocols like Modbus and Profibus for easy integration into third-party systems.

5. What temperature range can the Triconex 9853-610 handle?

The device operates efficiently in temperatures ranging from -40°C to +70°C.

6. How is the maintenance of this system managed?

It comes with advanced diagnostic tools that simplify troubleshooting and maintenance, helping reduce downtime.

7. What is the typical power consumption of the Triconex 9853-610?

It consumes around 10W of power.

8. Is the product suitable for outdoor installations?

Yes, the system is designed to operate in harsh environments and is weather-resistant, making it suitable for outdoor installations.

9. What communication protocols are supported?

The product supports Modbus, Profibus, and Ethernet communication protocols.

10. What is the weight of the Triconex 9853-610?

The product weighs approximately 2.5 kg.

Recommended Models

Here are six related models from the Triconex series that you may find useful:

| Model | Description | Key Features |

|---|---|---|

| Triconex 9853-620 | Similar safety controller with enhanced diagnostics | Improved monitoring capabilities |

| Triconex 9853-650 | High-performance controller for large systems | High availability and reliability in critical operations |

| Triconex 9860-700 | Advanced version with expanded I/O support | More I/O channels, ideal for complex installations |

| Triconex 9852-610 | Compact and cost-effective solution for smaller setups | Smaller form factor with all essential features |

| Triconex 9854-610 | Controller with higher processing power | Faster response times for time-sensitive operations |

| Triconex 9860-600 | Entry-level safety controller | Ideal for small to medium-sized systems |

Popular Models from Triconex

Here are six other popular Triconex models:

| Model | Description | Key Features |

|---|---|---|

| Triconex 9651-500 | Safety I/O module | Reliable, high-density I/O configuration |

| Triconex 9620-700 | SIL3-certified emergency shutdown system | Perfect for emergency safety shutdowns |

| Triconex 9622-200 | Small form-factor emergency control system | Compact and flexible, ideal for constrained spaces |

| Triconex 9630-600 | Power plant controller | Designed for high-demand, industrial applications |

| Triconex 9645-300 | Modular I/O for critical applications | Expandable I/O with redundancy options |

| Triconex 9650-900 | Real-time monitoring system | Excellent for real-time diagnostics and control |

Excellent PLC

Excellent PLC