| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

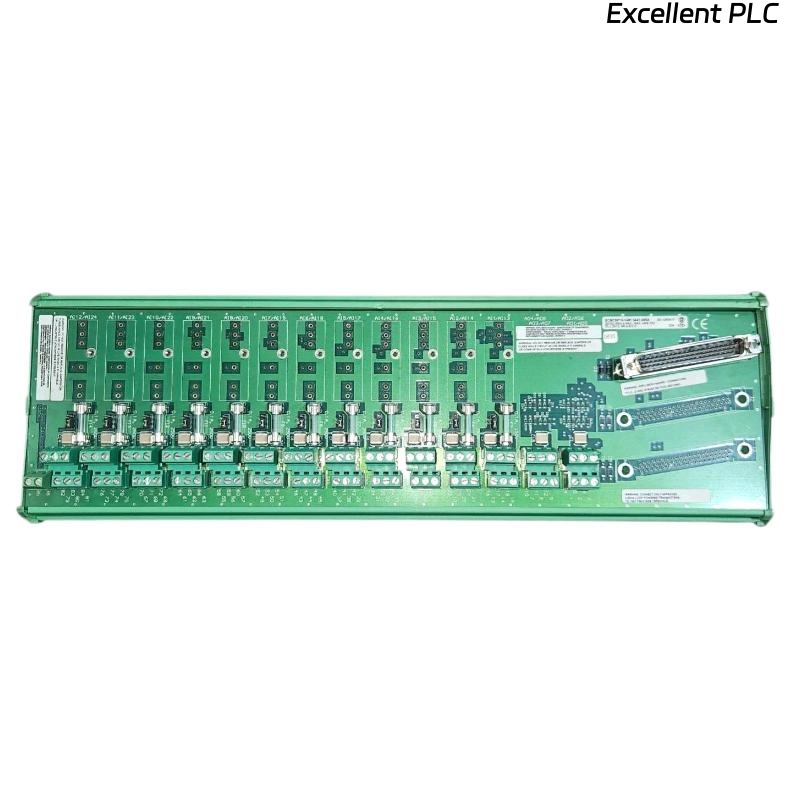

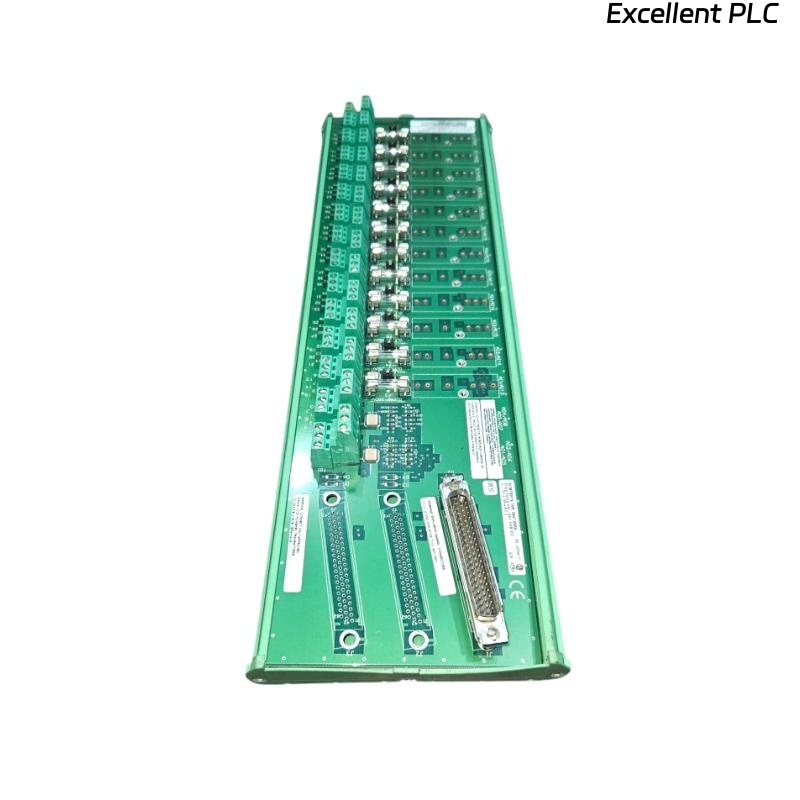

The Woodward 5441-695 DataForth FTM Module is a field termination module (FTM) designed to facilitate the integration of Dataforth signal conditioning hardware with Woodward control platforms such as the MicroNet and MicroNet Plus systems. As a specialized interface module, the 5441-695 provides secure, efficient, and organized signal routing between field devices and control systems.

The FTM module supports a variety of analog and discrete signal types and ensures signal integrity through isolation and noise reduction features. It is an essential part of systems requiring accurate signal conversion and high-fidelity transmission across industrial environments. This module is especially useful in turbine, engine, and process control applications where robust I/O connectivity and conditioning are required.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 5441-695 |

| Module Type | DataForth Field Termination Module (FTM) |

| Signal Support | Analog voltage, analog current, discrete (digital) signals |

| Compatible Signal Range | ±10 VDC, 4–20 mA, TTL, 24 VDC |

| Connection Type | Screw terminals (field side), plug connectors (controller side) |

| Isolation Type | Optical and galvanic isolation |

| Channels Supported | Up to 32 input/output channels (depending on signal type) |

| Compatibility | Dataforth SCM5B modules, MicroNet & MicroNet Plus systems |

| Diagnostics | Signal status LEDs, fault monitoring (with controller support) |

| Operating Voltage | 24 VDC nominal |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Mounting Method | Panel or DIN-rail mounted |

| EMC Compliance | CE compliant, industrial-grade immunity |

| Dimensions (W x H x D) | 120 x 180 x 40 mm |

| Weight | 0.38 kg |

Product Applications

The 5441-695 FTM module is used in systems that demand accurate signal conditioning, isolation, and reliable data transmission between field sensors and control processors. Typical use cases include:

-

Turbine and Engine Control Systems

-

Industrial Process Automation

-

Power Plant Monitoring Systems

-

Compressor and Pump Control Panels

-

Signal Isolation and Conditioning for Harsh Environments

-

SCADA and Remote I/O Interfaces

-

Safety-Critical Signal Routing Applications

Product Advantages

-

Flexible Signal Compatibility

Supports a wide range of analog and digital signal types, including voltage and current loops. -

Seamless Integration

Designed to interface directly with Woodward MicroNet platforms and Dataforth SCM5B signal conditioning modules. -

Enhanced Signal Integrity

Built-in optical and galvanic isolation minimizes noise and prevents ground loops. -

Robust Diagnostics

Integrated LED indicators and system compatibility enable real-time signal monitoring and fault detection. -

Industrial Ruggedness

Built to operate in high-temperature, high-noise environments with robust electrical immunity. -

High Channel Density

Offers up to 32 I/O channels per module, reducing panel space and simplifying system architecture. -

Reliable Termination

Field-tested screw terminals and modular plugs ensure secure, vibration-resistant connectivity.

FAQ

-

Which signal types can the 5441-695 module interface with?

It supports analog voltage (±10 VDC), current (4–20 mA), and discrete signals (TTL, 24 VDC). -

Can I use Dataforth SCM5B modules with this FTM?

Yes, it is specifically designed to support the Dataforth SCM5B signal conditioning series. -

Does the module provide electrical isolation between channels?

Yes, it features optical and galvanic isolation to protect the system from noise and transients. -

How many channels are supported on one module?

The module supports up to 32 channels, depending on configuration and signal type. -

Is it compatible with Woodward MicroNet Plus controllers?

Yes, it integrates fully with MicroNet and MicroNet Plus systems. -

Does the module offer any onboard diagnostics?

Yes, it includes signal status LEDs for each channel and supports fault feedback to the controller. -

Can it be mounted on a DIN rail?

Yes, it supports both DIN-rail and panel mounting options. -

What is the input power requirement?

It operates on a nominal 24 VDC power supply. -

Can it isolate analog and digital signals simultaneously?

Yes, the module is designed to handle mixed signal types with channel-specific isolation. -

Does the module meet industrial EMC standards?

Yes, it is CE compliant and built to meet strict electromagnetic compatibility (EMC) standards.

Related Models (Same Series or Functional Group)

| Model Number | Description | Function | Special Feature |

|---|---|---|---|

| 5441-693 | Standard MicroNet FTM Module | General I/O termination | Compatible with most I/O cards |

| 5441-694 | FTM for Discrete Digital I/O | Digital signal routing | Optimized for high-speed digital inputs |

| 5441-696 | Isolated Analog Input FTM | Voltage/current signal interface | Enhanced channel-to-channel isolation |

| 5441-697 | Thermocouple Signal Conditioning FTM | Temperature sensor interface | Built-in cold junction compensation |

| 5441-699 | RTD Interface Module FTM | RTD temperature sensor interface | 2/3/4-wire RTD compatibility |

| 5441-700 | Pulse/Frequency Input FTM | Speed/flow sensor interfacing | High-resolution pulse capture |

Popular Models from Woodward

| Model Number | Description | Application Area | Key Features |

|---|---|---|---|

| 505XT | Steam Turbine Digital Governor Controller | Steam turbine control | Redundant support, auto-tuning |

| 2301E | Speed and Load Sharing Controller | Generator and engine control | Flexible PID control, analog/digital I/O |

| Atlas II | Programmable Control Platform | Turbine and compressor control | IEC 61131-3 compliant, modular architecture |

| Peak150 | Digital Speed Control Module | Diesel/gas engine speed control | Field programmable, compact form factor |

| Flex500 | Modular Automation Controller | Process and turbine automation | Multi-loop control, SCADA-ready |

| 9905-940 | Synchronizer and Load Controller | Power generation systems | Auto sync, multi-generator load control |

Excellent PLC

Excellent PLC